MiniMill Table Accuracy

MiniMill Table Accuracy

Home › Forums › Workshop Tools and Tooling › MiniMill Table Accuracy

- This topic has 20 replies, 9 voices, and was last updated 11 November 2011 at 09:53 by

Peter G. Shaw.

-

AuthorPosts

-

19 April 2011 at 14:12 #67138

Peter G. Shaw

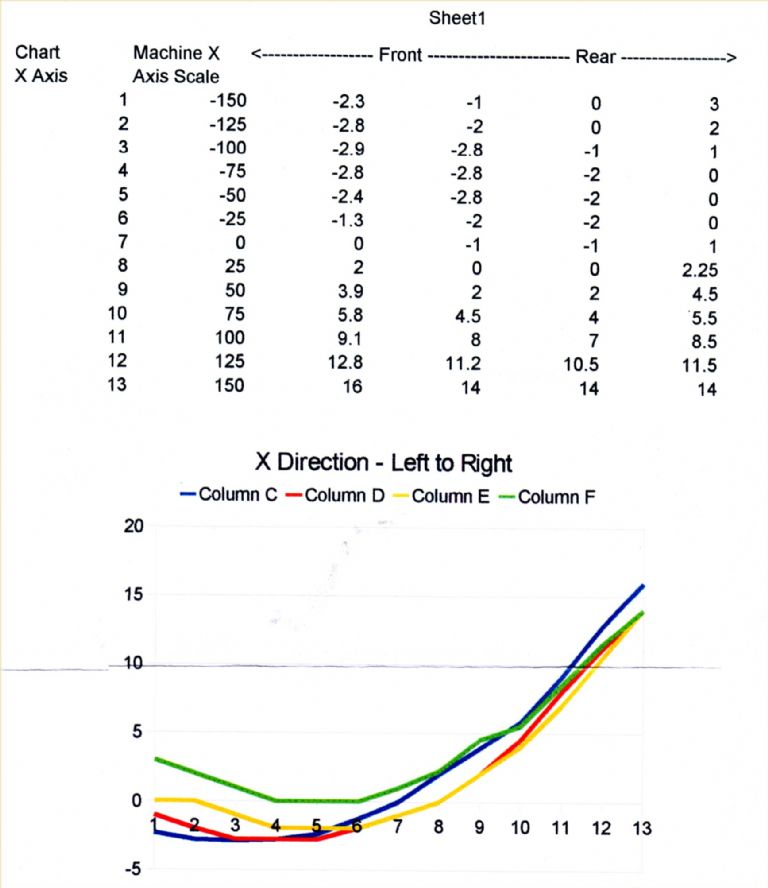

Participant@peterg-shaw75338Hi Folks,I’d like some thoughts on a problem I think I have with my 2008 Warco MiniMill. In brief, I think I have a problem with flatness of the table and would welcome thoughts on how to prove it further and/or what to do to it. I have thoughts of my own which I will put in as I go through.At this point it is worth pointing out that I am well aware of the problems associated with Chinese machinery, but would like to improve it if possible.Above is a table of readings, and the resultant graphs. I have done this twice on two separate days and although the actual readings differ, probably due to different postioning of the dti, the graphs are for all practical purposes identical.Here is what I did.I mounted a plunger type dti with its spindle almost exactly under, and in line with the machine spindle. The head, and hence dti, were lowered onto the table to show about 2mm deflection. (I do not think that the actual deflection matters.)The table was then moved to one end of the X travel and readings on the dti then taken every 25mm for the full length of the available travel.The table was then moved in the Y direction to place the dti on another of the four ground rails making up the table top, and the measurement exercise repeated. Note that when moving the table in the Y direction, rather than move the actual milling head, I lifted the dti spindle by hand when crossing the slots in the table. I did this because I thought that moving the head would result in loss of vertical positioning and hence loss of measurement accuracy.In the data table above, column 1 refers to the X numbers on the graph. Column 2 is the actual measurement scale on the front of the X axis of the table. As you will see, this150mm – 0 – 150mm. Columns 3 to 6 are the readings taken on the dti and are effectively plus/minus zero, where zero was actually 2mm. (Hope that makes sense.) Finally column 3 is the rail nearest the operator/front whilst column 6 is the rail farthest away, ie nearest the machine vertical column.As you will notice, there is a large deflection at the right hand side and a much smaller one at the left hand side.Obviously, the question is where is the discrepancy?Is the table out of truth? As far as I can tell without an accurate known straight edge, it does appear to be.Is it possible that the table is designed to be concave to allow for bending when subjected to weight? But considering that the measurements were taken at a point where the table is fully supported underneath this does not seem realistic.Could it be that the actual dovetail slides are wrong? In this context, please note that David White some time ago bought an X-Y table and promptly used lapping powder to improve the slideways. It is my intention to do the same as some of the slideways frankly look to have been carved out with an angle grinder.It seems to me that what I need to do is to firstly make new gib strips as the originals have triangular depressions in them as caused by a drill bit which has not started to cut correctly. The new gib will be fitted with 4mm ball bearings on the end of the adjustment screws.Secondly, to lap the slides as per David White.Thirdly, to skip the top in situ using a high speed TCT cutter.Another comment is that I think the table also tilts in the Y or back to front direction, but that could be that the head requires shimming.Ok, comments please.Regards,Peter G. Shaw19 April 2011 at 14:12 #16643Peter G. Shaw

Participant@peterg-shaw7533819 April 2011 at 15:29 #67143Roger Woollett

Participant@rogerwoollett53105I wonder if the table is tilting. Replacing the gib strip sounds a good idea. While you are at it look at the dovetail on the other side. It has been known for the “point” to be too sharp and not allow the proper surfaces to mate.19 April 2011 at 16:09 #67145dcosta

Participant@dcostaHello Peter!Good afternoon.For some months I also had a suspicion (like Yours) about my milling machine, an Optimum BF20.

A few days ago, when working on a important part of my shaper I decided to use my recently made tram tool (yes, one that uses two DTI) to test it and also to tram my milling machine and finally know if it has a problem or not.

So I trammed the milling machine and by the way, even knowing I can do the same without the tram tool, I could do a quicker operation with the new tool.

At this point I must say I used to test the alignment of the table using an articulated arm to support the DTI with a magnetic base attached to the metal bench board underneath the milling machine. And I found that the side where the table stood up was the side opposite to that where the magnetic base of DTI support stand.

After the tram of the milling head and not finding any reason to explain the difference of about 0.10mm I decided to use another support and magnetic base for the DTI, which being shorter, couldn’t be attached to the same board. Instead I had to fix it to the metal face of the column (which is rectangular) of the milling machine.

Surprise, surprise…: the table was perfectly flat. The explanation I find is that the weight of the table when it is coming more to one side slightly distorts the board on the other side. Ant with it goes the DTI…

Perhaps there is another explanation but by now I can’t find …Hope this helpsDias CostaEdited By Dias Costa on 19/04/2011 16:16:28

19 April 2011 at 17:46 #67153Peter G. Shaw

Participant@peterg-shaw75338Roger,Will bear that in mind next time I dismantle.Dias,All my measuring was from the mill spindle itself. I had wondered about trying it from the metal bench it sits on, but your report makes me think it is a bad idea.In respect of tramming, I only have a single dti, and yes I have seen the double dti tool and even considered making it. My tramming was done from the spindle itself, that is with an adaptor in a collet which in turn is tightened into the spindle. The dti is then fastened to the adaptor on a long arm so that I can swing it from side to side. The table testing was done using the same spindle adaptor, but with an attachment that allowed the dti spindle to be aligned with and under the machine spindle.Graham,Sorry for the misleading lack of info. It is the old thing, I know what I mean and I subconciously think you know what I mean as well. Anyway, the reading -2.3 actually means 0.023mm less than the zero (2mm) position. In effect, I use the 2mm loading on the dti as a pseudo zero and then measure + and – from that. So -2.3 is actually 2.00-0.023 = 1.977mm. A minus reading means then that the dti is reading less which means that that part of the table is lower than the zero or 2mm position, whilst a plus reading means that the dti is reading more which means that the table is higher than the pseudo zero point.The mill is the Warco MiniMill, which is an X2 clone. (Warco will hang me for saying that as it is actually made by Real Bull.) I do not have a known good 12″ steel rule: perhaps something for Harrogate. I do have issues with Rabone and Chesterman as I have one of their 6″/150mm rules which is noticeably out on the metric scale compared to another 5 cheap rules, and I find it rather difficult to believe that all 5 , or is it 6, rules are incorrect whilst the one Rabone & Chesterman is correct. Strangely, the imperial scales all agree. Rather than use Silver Steel, I did wonder about PGMS, or more likely, a length of gauge plate since that appears to be ground to specific limits. Another possibility may be to use three lengths of ms flat and grind one edge of each piece together using valve grinding paste in a similar fashion to making surface plates.I do not think that the gibs are slack, but then as I have no other engineering experience, I have nothing to compare against. To adjust them, I generally nip them up until I can no longer detect any sideways movement of the moving slide at either end of fixed slide, whilst ensuring that the slide can move easily without binding. I also use Rocol Slideway spray. Since I detect movement by feel, I suppose it is possible that they may be on the slack side.The reradings were taken with loose locks. Tomorrow I will repeat the tests but this time locking all slides for each test.(As a rather off topic thing about feeling things, I went on one training course, rattled through the practicals and was then given a problem, which I was assured would slow me down. It did not and I cracked the problem literally in a few seconds. How? Well, the practical was on equipment containing a lot of relays and this particular fault set up an inter-action between three of the relays. By placing my fingers gently on the relays, I was able to detect the sequence, a quick look at the diagram, and straight to the one and only thing it could be. Needless to say, the instructors were not exactly excstatic.)Regards,Peter G. Shaw19 April 2011 at 20:38 #67164Pat

Participant@patHi PeterSince I am having problems posting this may end up as a duplicate for which I apologise to everyone in advance.I have a similar mill XJxx12 on the bench for conversion to CNC. This mill has had no serious use other than cutting a bit of delrin. I have repeated your X axis test and find that the table is within 0.005 mm +/- over the full 300mm traverse. The same result is obtained using either the rear edge of the table or the front edge. The gibs are adjusted on the light side and are as supplied. I have verified the tram for both X and Y and my sample is OK.May I suggest you start by verifying that the tilt adjustment on the mast is set correctly. The general shift in your graphs would indicate that the mast requires tramming. The Z – X plane is most readily adjusted via that big nut on the back of the machine having first removed the locating pin. Take care as the mast is heavy and can topple out of control. A rope to the ceiling is good if you can arrange such a thing in the interest of safety.I also suggest that the gibs are not the main contributor to your problem until you start to do some cutting.Correcting the tram with the curves you have plotted should end you up with something of the order of 0.02mm +/- on the X over the 300 mm travel and 0.01 or better over the shorter Y traverse.Tramming (adjusting the mast to be at right angles to the table) details for the X2 are available on the web. Ask if you can’t find them.Hope this helps – Regards Pat19 April 2011 at 22:22 #67176Pat

Participant@patHi PeterNote that you are off line at present so may I suggest that you again look at the curves you have so magnificently plotted. Take one say the blue curve joint the two ends with a straight line and try and imagine the slope which is anti clockwise. A bit more imagination will let you average the correction. This means that the mast is tilted and requires moving clockwise to correct the general tilt of the curves. This will greatly reduce the deflection on the DTI. If you repeated the same measurements but traversing the Y axis using the ends of the table as the reference you will probably see a similar off set in which case the remedy is to shim the base mounting of the mast to the base of the mill casting under the two screws either side of the mast.However the WARCO / Red Bull mills are in my experience reasonably well set up at the factory so it is unlikely that the head will be significantly out of parallel with the mast. Again the procedure for shimming this is well described on the web but requires the mill to be pulled to pieces to separate the two castings making up the head housing. See the illustrated parts list to get an idea of what is involved!As a general observation check the tram each time you start out making a valuable part. There are some fancy dual DTI bits of kit sold for this but a single DTI and mount will work as well but take a bit more time and a bit of care to achieve satisfactory results.This all takes more words to describe than to check!Regards – Pat19 April 2011 at 22:42 #67177Les Jones 1

Participant@lesjones1Hi All,I do not think poor tramming would influence these results. The only time the Z axis is moved during these tests is to bring the DTI in contact with the table so the Z axis not being perpendicular to the X and Y axis would not matter.Les.20 April 2011 at 02:51 #67187Pat

Participant@patHi LesI still think Peter’s main problem is with tramming as the figures he has posted indicate he has a table that is higher at one end than the other. (There are also some other problems evidenced in the figures but the mast being out of square to the X axis is the worst.)These mills have a mast that can be pivoted to achieve inclined machined surfaces. The figures and curves indicate the right hand end of the table is some 10 to 15 mm high. Tramming will correct this and from the curve shape he should then expect to find a traversing error of +/- 1mm or less. It is difficult to estimate this with out printing the curve but it should be of this order.Try thinking of the machining a wedge on this mill and you will see what I am trying to describe. However I might be wrong but having seen this problem with the tilting mast mills before I might be jumping the gun as I hate the reduction in rigidity introduced by the mast pivot. The Warco / Red Bull has more metal and some better machining than some of the other X2 designs but it is still a weak point.Hope this explains my reasoning – regards Pat20 April 2011 at 04:04 #67189Pat

Participant@patHi Les& PeterSorry I now see what you are saying Les. Yes Les is right this is not a tramming issue.Peter please ignore my posts about checking the tram. My error in getting my pet hate with the mast pivot as the cause of the tilt to the curves yo have plotted Peter.The lack of squareness is with the motion of the X axis with respect to the table top not with respect to the mast.The central casting of the crossed ways would be my hunch as to where the error is. Check that the dove tails are properly seated – clean and free from raised dings or crud. Someone else has pointed out the need for clearance at the base of the dove tail on the non gib side. The size of the discrepancy / foreign body you are looking for is the equivalent of about 3mm as seen at the cross slides I calculate form the apparent skew of the curves.Striping the cross slide arrangement is relatively easy as is the reassembly.Very embarrassed by my jumping to conclusions about the tramming and thanks to Les for pointing out my error.Good luck Peter hope you sort this out without spending real money as there will be loads to covert at Harrogate.Regards – PatEdited By Pat on 20/04/2011 04:05:50

20 April 2011 at 10:08 #67201Peter G. Shaw

Participant@peterg-shaw75338Hi folks,No I have not done anything yet – it is too early in the day for me.However,…Pat,Tramming, or rather a slight lack of it, was how I originally came to the conclusion there was something wrong. I then set the tram to try to achieve a balance, although not too well perhaps.This does suggest another avenue to explore, ie to reset the tram to balance the L-R using just one of the rails. (Incidently, what is the correct name for the rails?) Then repeating the tests.Graham,This machine has two handwheels on this slide, however I only ever use the right hand side one. Partly because I am mainly right handed, but also because it is more convenient as I can stand at that end.All readings are taken the same way, although not necessarily in the same direction of travel. Reading 1 is when the table is at extreme right hand position. Reading 13 is taken when the table is at extreme left hand position. In other words, Reading 13 is taken when the right hand hand-wheel (and associated components) are almost hard up against the fixed portion of the slide.Now then, the brain cells have started working. This means that the weight of the slide is concentrated on the left hand side of the base structure, and this in turn will cause a tilting effect with the LHS trying to move down, and the RHS thus trying to move up – which is exactly what the readings are saying. This could also be happening at the other extreme because the graphs are tending to show this. Which could possibly be slack gibs.Hmm, lots more testing to do.There is one other thing which may be a pointer towards me having set the gibs not tight enough. I have read somewhere that some people have changed leadscrew sleeve bearings to ball bearings thus allowing the rotary motion to beome much easier. In turn, this has allowed the gib stribs to be tightened thus reducing the slack on the slide. This machine is already fitted with what I believe are thrust ball bearings at each end of this slide. Possibly another pointer to slack gibs.Whew, what a lot to do!I shall report back.Peter G. Shaw20 April 2011 at 16:47 #67222Dusty

Participant@dustyPeterremember to check both x and y axes, as you will no doubt realize slackness in one can effect the other. A good test is to remove the leadscrew and try pushing the table up and down the machine. If you can push it without any effort it is too slack. You should feel some resistance.20 April 2011 at 17:54 #67224Pat

Participant@patHi PeterI have just removed the table form the XJxx12 and found there is very little clearance between the edge of the dovetail and the dovetail recesses. On this example there was dirt impacted in the recess that was causing some problems with the gib adjustments hence the strip down clean and lube with slideway spray on oil.Having reset the gibs I measured the turning force using a spring balance on the handle at it requires 1.5 Kg to get the axis moving and about 1 Kg being sufficient to keep it on the move.During the CNC conversion I intend to improve the clearances at the root of the dovetails and to lap / polish the inclined faces as they are full of parallel groves but otherwise OK.After the exchange from Lee and in the light of the crud I found impacted in the root of the dovetail on the X axis it might be worth cleaning this out. Simply remove the two socket headed screws at each end of the table slacken the nut in the centre of the hand wheels – remove the gib screws and the gib can be slid out by rotating one of the table end plates. The table then lifts off. Take care as mine had some very sharp edges and I sliced my thumb! Clean and reassemble.Regards – Pat20 April 2011 at 19:58 #67239Pat

Participant@patHi GrahamPoint taken and I might even try and scrape them as I have the scrapers I was forced to make way back to sort out some very large cast base plates and for some reason they have followed me around for the last forty years. I am a great believer in the Rocol slipway for minimizing stick slip. Thanks for the timely reminder.Regards – Pat20 April 2011 at 20:10 #67242Peter G. Shaw

Participant@peterg-shaw75338Hello everyone – there are too many people to individually name!Here is what I have done today:Looked at the slides with the aid of a mirror and light. I did not want to dismantle without carrying out the test detailed below first. Noticed that one end of the gib was rubbing on the slide and has created a noticeable scratch on the surface. The other end was clear of the sliding surface.Mounted the magnetic dti holder on the bottom of the column, thus eliminating the column top and milling head, and set the dti approximately in line with the machine spindle. Repeated the tests. No real difference, ie still a large difference at the rhs.Then tried all the tests again but this time with both X & Y locked up tight for the measurement. Very slight difference as the X lock was activated, but overall no real difference.Removed the leadscrew and all its bits and pieces. Then tried pushing the table back and forth. Quite difficult to get started but then generally easy once moving. Checked for gib slackness with the table at each end of the travel. With the table to the right, there was no discernable slackness, whilst at the other end, there was a small amount of slack. A slight adjustment has eliminated most of the slack, and the table still moves back and forth under manual pressure.Also under this condition, although the dti was not moved (as far as I know), the actual readings were different, but the overall effect was the same of the rhs being high by about 0.25mm and as the graphs showed, the majority of the movement is at the rhs end, ie when the table is moving towards the left. To me, this indicates that there is some non-linearity somewhere.The slides and dovetail recesses all seem clean and oily – no bits sticking up. No dirt in the recesses.The Y slide is quite tight, however I will recheck this because there is the possibility that the handwheel adjustment may be overtight.I am now attempting to determine by means of an accurate straight edge whether or not the table and/or the dovetails are twisted or warped. This has been made more complicated by my discovery that one of my so-called surface plates, a granite table thingy bought following a recommendation on an early thread on this forum, is actually hollow. It does seem that my scratched glass plate may be flat and that an unused ruler out of a cheapish combination set (see thread elsewhere on this forum) may be ok to use as a straight edge. More experimenting tomorrow after cutting the grass!Someone asked how much use this machine has had. Answer is “not much”. It is nearly three years old, but spent most of months 2 to 13 out of action because I managed to break the plastic gears within the first month. And it becomes too darned cold in my garage in winter. Since the repair, all it has done is to trim up a pair of aluminium 3-way angle plates and some small bits of steel milling – nothing at all strenuous.Gib screws are flat ended. In an edition of MEW some time ago, there was a comment that a round end, eg ball bearing, was the best method to use. As it happens, I have a quantity of 4mm balls looking for a home and my intention is to make new gibs and make new screws complete with ball ends. However, to make new gibs requires me to create an angled surface, which requires something like a milling machine. Bit like the “There’s hole in my bucket” song. But now that I know I have problems, I can probably mill them using the better end of the table.Dovetail angle. Yet another problem to sort out. My initial measuring of the existing gibs suggests 62° which seems an odd sort of value. Now that I have removed the table, I can have a go at measuring the dovetails properly. Incidently, if the gibs are 62°, and the dovetails 60°, this would explain why the gib is cutting into the dovetail.If nothing else, this will keep me off the streets!Regards and thanks,Peter G. Shaw20 April 2011 at 20:27 #67243John Shepherd

Participant@johnshepherd38883From experience, I would not take it for granted that the

casting holding the spindle and the one with the vertical dovetails are in

alignment. They are held together with just 4 screws and no locating feature.

(If it is an X2).I had all sorts of problems setting up my X2 until I

realised this was the problem. What I

was doing when tramming the head was compensating for the misalignment. All was

well until the head was moved on the column from the position it was trammed

then it was inaccurate.Not the solution to your current problem perhaps but one to

watch out for.Edited By John Shepherd 1 on 20/04/2011 20:29:06

Edited By John Shepherd 1 on 20/04/2011 20:30:03

Edited By John Shepherd 1 on 20/04/2011 20:31:44

Edited By John Shepherd 1 on 20/04/2011 20:34:06

21 April 2011 at 12:31 #67281Pat

Participant@patHI PeterIt is the Y axis slide-way that should be checked at the table is tilted left to right. Cleaning and readjusting the X axis is good but they both need to be correct. . The Y slide way can be cleaned insitu with suitable solvent – white spirit is what I use as it does not cause rusting like paraffin does. The gib screws should be snugged down uniformly a bit at a time on each screw. If you hold the allen head grub screw still and nip up the locking nut they will be just a bit on the tight side. Slacken each one off 1/8 turn at a time so that the hand wheel turns under a firm but not excessive action or if the lead screw is not fitted you can just push the table. (It is important that each screw is treated equally when slackening off.) The travel should be smooth from one end to the other. I assume you have checked the gib strips are flat and not bent as it is important that the gib makes good contact along the entire length with the dovetail slope as well as having all the gib screws set to the same pressure. The gib strips on the machine I have on the bench fro conversion fill the gaps with just visible clearance as well as being flat and with a good finish on the working faces.Since the gib is there to force the sliding part down onto the flat reference surface I suggest that the angle of the top and bottom surface is not critical provided the top is free from sharp edges and burrs. On the sample I have they are nicely rounded.I still suspect that you have dirt in the Y axis slide on one side and that this is lifting the way off the reference surface having the effect of tilting the table. If you are going to strip both X & Y slides then this can be checked by manually positioning the slides less the lead screws and gibs and using the DTI to verify that the table does not tip when it is repositioned resting on the flat surfaces (reference faces) of the ways. You could also check that the sharp edge of the dovetail has clearance on the mating recess. On the mill I am working on the recess clearance is minimal and I will increase this by filing away a little of the sharp edge.Good luck with the investigation. Regards – PatEdited By Pat on 21/04/2011 12:32:59

10 November 2011 at 21:00 #77629Peter G. Shaw

Participant@peterg-shaw75338Hi folks,An update on the above problem.I sent the table to Brian Caddy of Slideway Services for regrinding. I have today received notification that it is now ready to be returned, along with the comment that this was one of the worst tables that he has ever had to regrind.Which suggests that all my testing was absolutely spot on.So it’s now down to a major rebuild of the machine, scraping and lapping the badly ground slides and making and fitting new gibs. I have done one so far, and taken the opportunity to a) fit locating pins as suggested by “Former Member” and b) fitted 4mm balls between the adjustment screws and the gib strip itself. In order to ensure that the dimples were correctly located, the gib was clamped to the main slide, a screw inserted with a 4mm hole down the centre, and a 4mm drill inserted to create a dimple sufficiently deep to take the ball. This predrilled screw was made in the lathe so the hole should be concentric with the thread.Unfortunately, this has lead to another problem in that the gib strip has to be in place before the two parts of the slide can be mated and this leads to other re-assembly problems. I think I can get round it, but if not, then it means that the locating pins may have to be screw-in instead of push-fit.Ah well, it all adds to the fun!Regards,Peter G. Shaw10 November 2011 at 21:11 #77632Sub Mandrel

Participant@submandrelHello Peter,I’m confident my X2 isn’t as banana-like as yours. Nonetheless, I had to scrape the joint of the column and the base – my first proper attempt at scraping, so it was long and slow and turned both the air and my fingers blue. End result, a front-back error of over a thou was removed and the whole set up became significantly more rigid.Neil10 November 2011 at 22:03 #77638blowlamp

Participant@blowlampPosted by Peter G. Shaw on 10/11/2011 21:00:33:…and lapping the badly ground slides and making and fitting new gibs…… fitted 4mm balls between the adjustment screws and the gib strip itself…Peter G. ShawPeter.If you’re still looking for contributions to this rebuild, then I’d have to advise you NOT to lap the slides and forget about fitting balls between the adjusting screws and gib strip.Remember that lapping will not discriminate between which surfaces it removes material, so if you’re planning on using your newly ground slide in this process, be aware that it too will be lapped.Use a scraper and a 3 cornered file etc to match the saddle to the slide, but leave the grinding paste out.As for the balls – what purpose do they serve?Because you’ve pinned the gib strip to locate it, there is no longer a need to drill any dimples, which is a good thing in my book because I find dimples can cause a slide to wedge tight at the most inopportune time.Why not make some push-pieces, with angled ends that reflect those of the dovetails, to interpose between the screws and the gib strib and are turned down and let in to the screw ends for support and location?Martin.11 November 2011 at 09:53 #77654Peter G. Shaw

Participant@peterg-shaw75338Martin,I must admit to having concerns about lapping in on the new slide, but if you could see the existing mating slides you would realise why I said it. Probably the best thing now would be to scrape using the newly ground slide as the master.Balls? (No, not being rude!).I’m not an engineer, hence I am attempting to incorporate the suggestions made by other people,and the fitting of balls was one of them. In fact, the particular article said that this was probably the best of all possibilities and as it seemed relatively easy, I decided to do it. It is of course entirely possible that I am going well and truly over the top with this.The idea of push pieces, made from copper or brass, may well be a possibility. I say copper/brass because my lathe uses them in a couple of places, one being the locking screw for the saddle, and I assume is used because it is softer than steel.What is certain is that I wito look most carefully at how the machine is assembled as what I have already done has made re-assembly somewhat more difficult.Regards,Peter G. Shaw -

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Workshop Tools and Tooling › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Milling for beginners book, Where?

Started by:

andy198712 in: Beginners questions

- 8

- 14

-

24 August 2025 at 22:48

Mark Easingwood

Mark Easingwood

-

Bending copper tube?

Started by:

Bo’sun in: Workshop Techniques

- 7

- 7

-

24 August 2025 at 22:17

Macolm

-

Lathe tool inserts

Started by:

Andy Brocklehurst in: Beginners questions

- 3

- 5

-

24 August 2025 at 22:13

Andy Brocklehurst

-

Recommendations for book on clock repairs

Started by:

Andy Stopford in: Clocks and Scientific Instruments

- 4

- 4

-

24 August 2025 at 21:40

Brian Merrifield

-

Quartz clock movement

Started by:

duncan webster 1 in: Electronics in the Workshop

- 2

- 3

-

24 August 2025 at 21:37

duncan webster 1

-

THE MAUDSLAY TABELE ENGINE

Started by:

sivtek1 in: Stationary engines

- 4

- 7

-

24 August 2025 at 20:27

Michael Gilligan

Michael Gilligan

-

Progress no.1 restoration

Started by:

flyingsailor in: Workshop Tools and Tooling

- 9

- 12

-

24 August 2025 at 19:52

duncan webster 1

-

A4 stainless

Started by:

David Ambrose in: Materials

- 14

- 22

-

24 August 2025 at 19:15

old mart

-

Blackgates 3 Way Toolpost Casting

Started by:

John McCulla in: Materials

- 13

- 23

-

24 August 2025 at 19:00

duncan webster 1

-

Softening epoxy

1

2

Started by:

John Haine in: General Questions

- 18

- 26

-

24 August 2025 at 18:59

old mart

-

Joined 24 August 2025

Started by:

simon912 in: Introduce Yourself – New members start here!

- 3

- 3

-

24 August 2025 at 18:59

noel shelley

-

The stand alone weight for tower clock

1

2

Started by:

dk0 in: Clocks and Scientific Instruments

- 12

- 38

-

24 August 2025 at 18:33

bernard towers

-

Denford Orac refit

Started by:

Richard Evans 2 in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 3

- 5

-

24 August 2025 at 16:59

Richard Evans 2

-

Manual for Warco GH750 or Chester Cub 630

Started by:

Gavlar in: General Questions

- 7

- 17

-

24 August 2025 at 16:03

Gavlar

-

THE MAUDSLAY TABELE ENGINE

Started by:

sivtek1 in: Introduce Yourself – New members start here!

- 2

- 3

-

24 August 2025 at 11:57

sivtek1

-

CNC Coolant

1

2

3

Started by:

Steve355 in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 13

- 53

-

24 August 2025 at 11:37

Steve355

-

Phone Phreaking

Started by:

Michael Gilligan

in: Clocks and Scientific Instruments

Michael Gilligan

in: Clocks and Scientific Instruments

- 11

- 14

-

24 August 2025 at 11:35

John Haine

-

QCTP for chester lathe

1

2

Started by:

Chris12 in: Beginners questions

- 11

- 26

-

24 August 2025 at 11:11

dk0

-

Material advice

Started by:

tobyonekenobi in: Materials

- 10

- 21

-

24 August 2025 at 10:57

tobyonekenobi

-

Model Aircraft Engine

Started by:

Alan Charleston in: Suggested Online Resources

- 2

- 2

-

24 August 2025 at 09:38

Michael Gilligan

Michael Gilligan

-

Smart & Brown Model L lathe help required

Started by:

AJAX in: Manual machine tools

- 1

- 4

-

23 August 2025 at 21:45

AJAX

-

This weeks oddity!

Started by:

Martin King 2 in: Help and Assistance! (Offered or Wanted)

- 4

- 5

-

23 August 2025 at 17:29

Martin King 2

-

Asong power feed?

Started by:

Hollowpoint in: General Questions

- 5

- 6

-

23 August 2025 at 16:55

Stuart Smith 5

-

New member, progress no.1 rest

Started by:

flyingsailor in: Introduce Yourself – New members start here!

- 5

- 7

-

23 August 2025 at 16:11

flyingsailor

-

My week this week! My workshop videos

1

2

…

11

12

Started by:

Phil Whitley in: The Tea Room

- 16

- 297

-

23 August 2025 at 16:05

Phil Whitley

-

Milling for beginners book, Where?

-