There's a couple of reasons

The original motor can happily run all day doing higher torque work, even my good old bosch drill is starting to give up the ghost from hole drilling in the press. Modern electric motors don't like being worked too hard

I don't want to be messing about with different electric motor mountings and fitting them onto individual gadgets around my cross slide and headstock

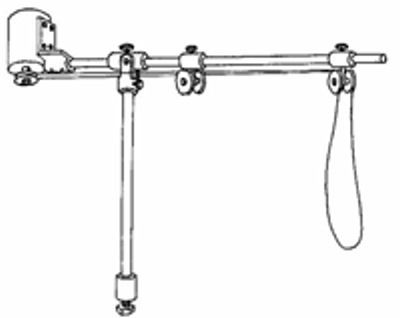

I would much prefer to have a simple belt pulley on each gadget where I snap on a small belt and it runs all day if required

This also means I have loads more room for the gadget, there's no motor setup in the way, only a small belt to the overhead drive

If I can sort the torque issue then I can do all sorts of things like a small power slotter for making gears with the workpiece in the headstock as an indexing tool

edit:

Finally, for whatever reason this kind of stuff pushes my buttons because it provides multiple solutions

Longer pieces can also be indexed and worked on along the length of the lathe, the old M series is an extremely strong stiff unit

If the job gets too tough the belting will slip, there's no more motor burn-out issues on these one-off big jobs we occasionally run into, so you can focus on solutioning the machining problem

Edited By Ady1 on 12/10/2012 12:06:05

Hopper.