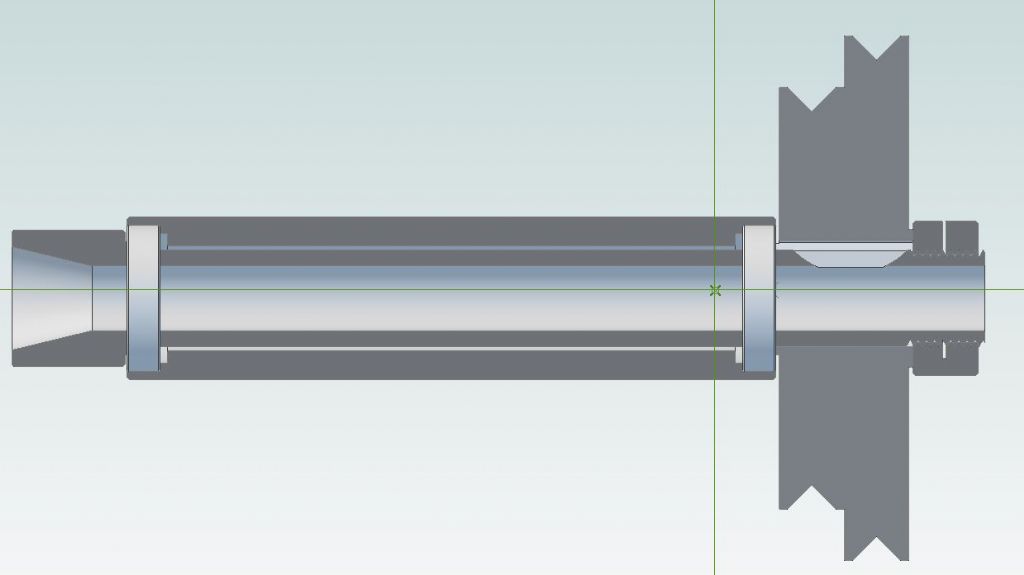

Plenty of small lathes just use a pair of ballraces for the spindle and end play is dealt with by threading the end of the spindle so a nut/nuts can be used to take up the play.

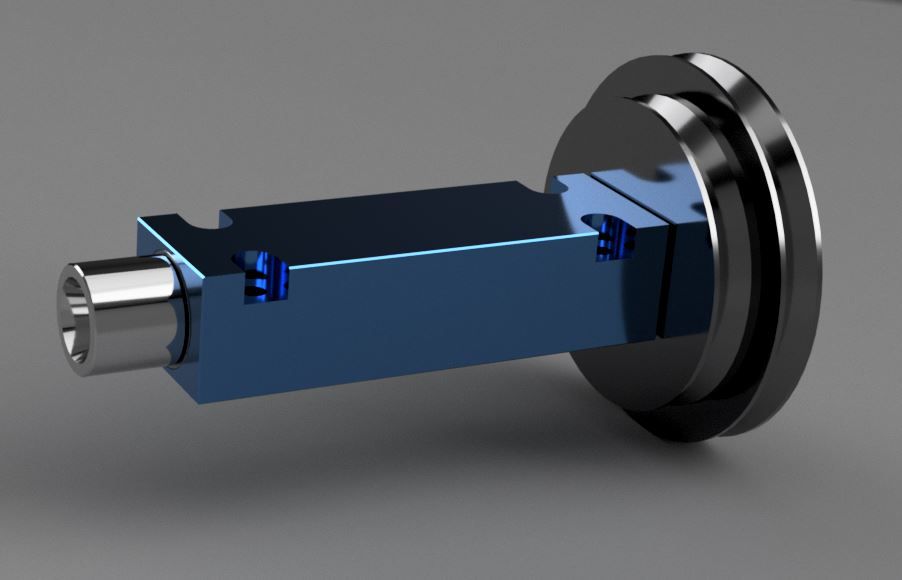

Assuming a 12mm dia spindle with a larger "head" to accomodate the collet taper then you can get thin ballraces 12mm ID and 18mm OD which you should be able to get into say a 20mm casing, could even narrow it down in the middle if you want to get it into a toolpost. This would mean a small amount of overhang due to the bearing not being around the widest point of the collet.

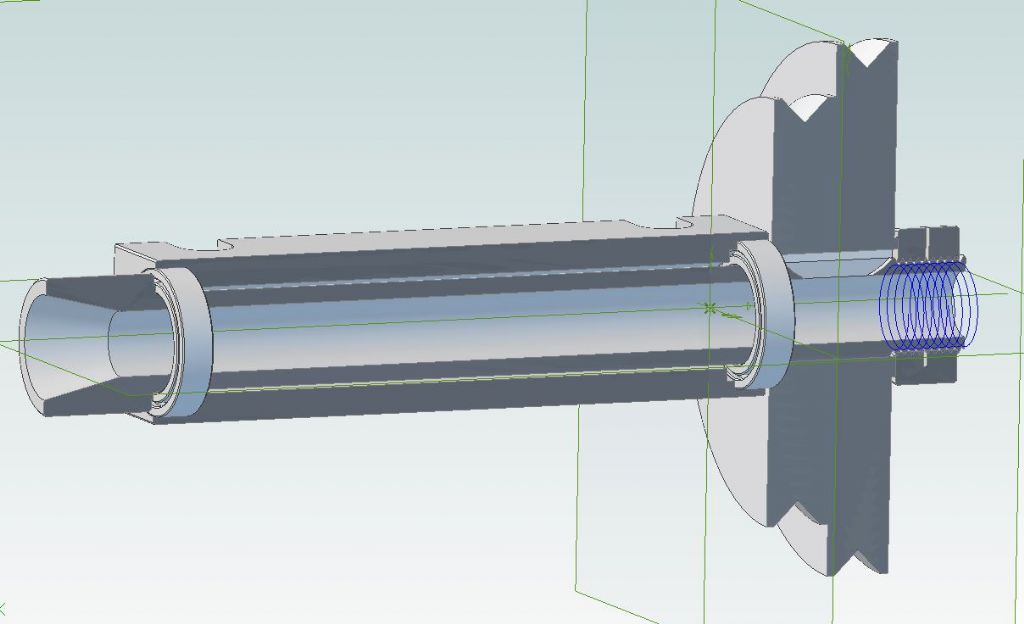

If you wanted to have the whole of the spindle within the bearings then you would need say a 15ID x 24OD thin bearing at the tapered end but could still use the smaller 12mm ID at the far end. Body would need to be 26mm or 1" at a push but could still be thinned down for most of it's length to make it easier to clamp but I would think one flat face would be a good idea.

The "head" would bear against the inside of one bearing and your fine threaded nut against the one at the opposite end. Spindle protrudes beyond the nut so your drawtube can bear on the end of the spindle

John Wright 19.