What started as a simple (CAD) depthing exercise between the wheel teeth and pinion leaves of John Wilding’s large wheel (290 x 8) skeleton clock, turned into a rather protracted undertaking.

See here … **LINK**

There were complimentary hints too, that I should instead direct it for M.E. publication. However, for various reasons I am no longer attracted to the idea. I had already enjoyed (and struggled) with submitting three articles and have a clear idea of how much work is involved.

As mentioned in other places, I have never carried out a practical depthing exercise of gear wheels/pinions. Perhaps I was lucky enough to get away with drilling the pivot holes in the skeleton clock plates even before I had cut the wheels, pinions and arbors. However, following John Stevens’ design, the clock has been running since about 2011.

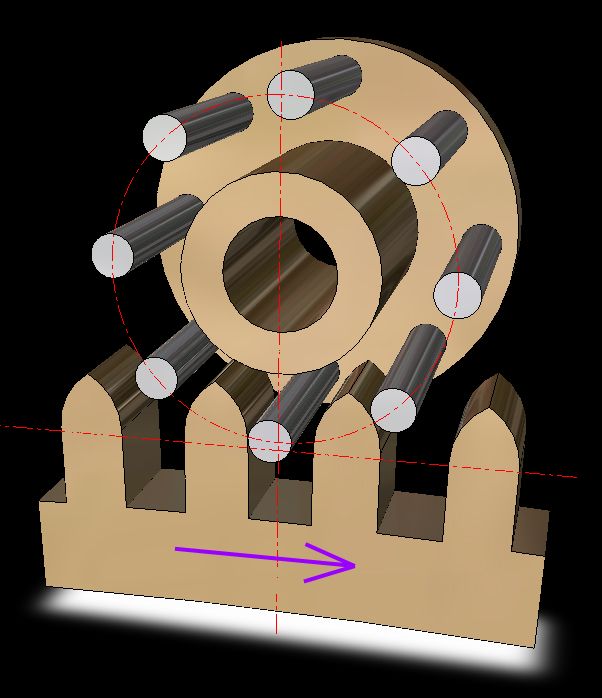

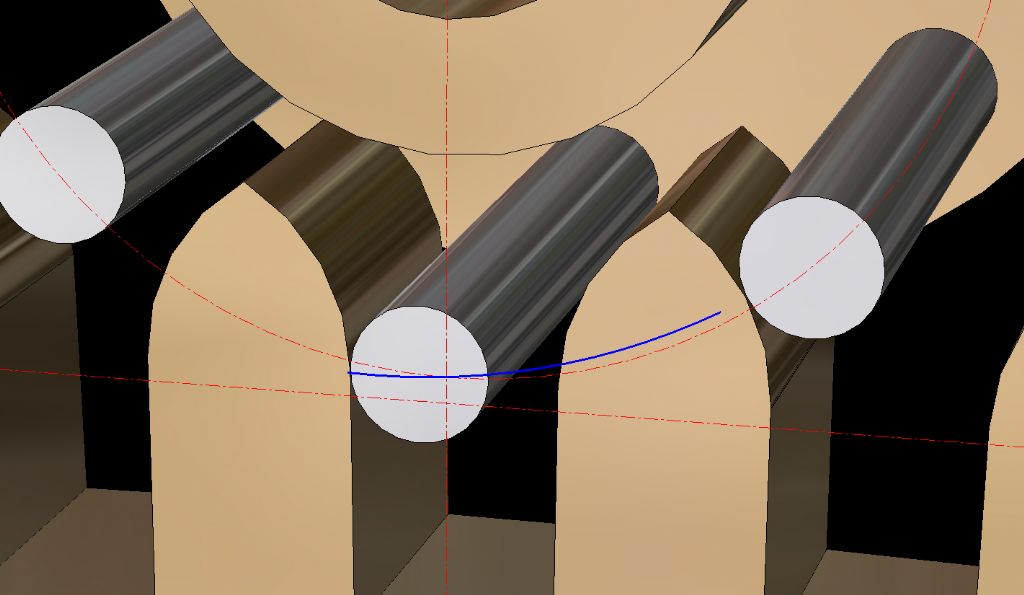

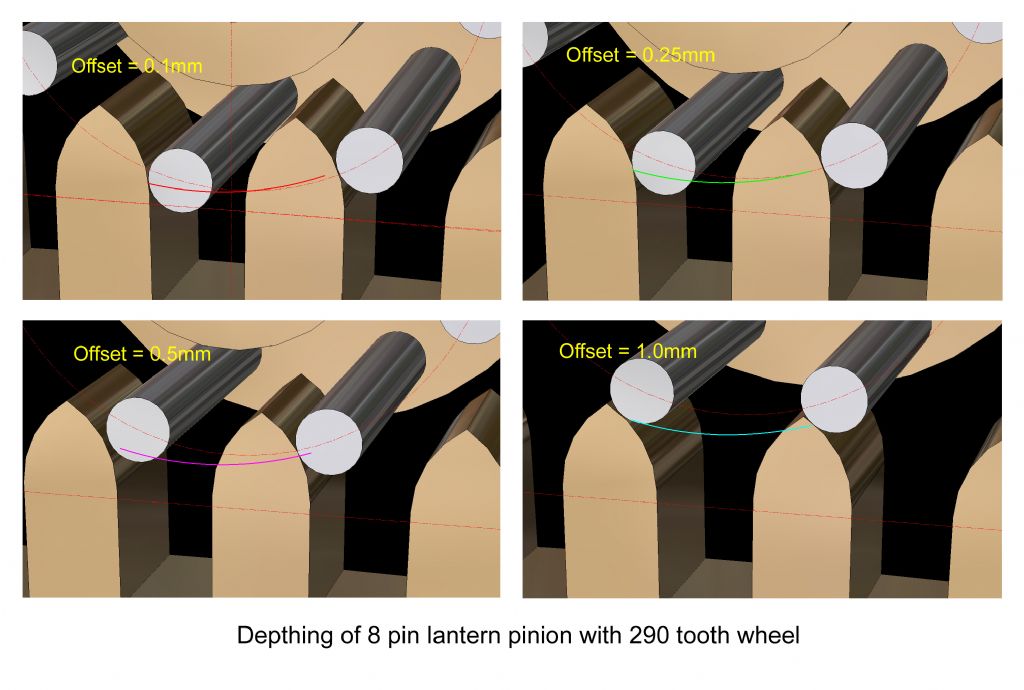

In conjunction with the meshing details in the previous thread, and Michael Gilligan’s interesting suggestion, these latest images show how an 8pin lantern pinion would mesh with the large (290tooth) wheel (refer John Wilding’s ‘Large wheel skeleton clock).

As before, I constructed the wheel teeth according to ‘involute’ data via BS 978: Part 2. The diameter of the lantern pins matches the thickness of the pinion leaves in the previous thread. Obviously, the front disc of the lantern pinion is missing for clarity.

As before, this series includes meshing-depth decreases from ‘on centre’ to include offset of 0.1mm, 0.25mm, 0.5mm, and 1.0mm. The wheel teeth drive the (pinion) pins to the right.

This is incomplete. Please go to Part B

Sam

Sam Stones.