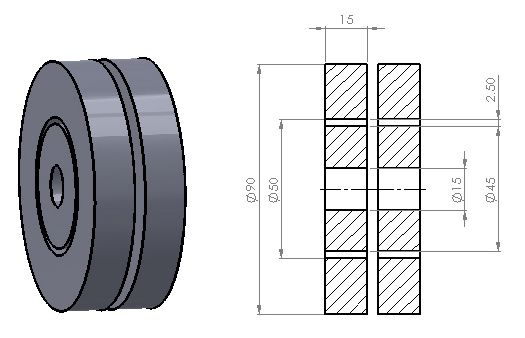

One thing I missed on this is the 100mm dia bar, maybe because cms were used. That's too big for the chucks that normally come with a southbend. The best bet for holding it would be the 4 jaw with the jaws reversed but even that is a bit risky without more support. The 4 jaw will hold work far more securely than the 3 jaw.

The best way to do it would be to use the fixed steady. Chuck the work, set the steady and face and centre drill the end. Remove the steady fit the centre and skim up the work right back to the chuck, just a light cut. Set the steady again, it now has a surface that is running true, leaving enough space to make the 2 smaller ones. Drill and bore, turn the od and part them off. Same with the larger ones but you will finish up with the steady rather close to the chuck. Maybe closer than it can get, you'll have to check. In that case you should be ok parting off the last one without the steady as the projection will be low.

When mounting it in the 4 jaw adjust the jaws to get it running as near true as you can not forgetting to tap the far end to get that running as true as the part in the chuck. Final adjustment if needed to get something very true is done while fully tightening the chuck. If that doesn't work out go back to adjusting the jaws. It takes a bit of practice.

I might have ordered up suitable slices of material but if the faces needed to be rather parallel an expanding mandrel would have to be made as well. Not easy with bores this large.

LOL this assumes that the bar is long enough of course which unless the measurements are messed up it isn't even if no material is wasted making them, 4 x15mm = 60mm which is > 40mm It's probably big enough to make 1 without any parting off unless the faces need to be parallel. The o/d could be turned by doing half and then reversing the work in the chuck and doing the other half, Bore and then part off and finish the thicknesses individually. They faces could be trued up to the bore and made parallel but that would need an expanding mandrel – easy to make for small bores but not for ones of this size.

John

–

Ian S C.