Posted by not done it yet on 24/05/2020 06:48:46:

A question I do have re cast iron, is it possible to surface harden cast iron, …

Some castings come with surfaces already hardened? 🙂 People sometimes go to considerable trouble to reverse that characteristic – or just send them back for a replacement.🙂

The usual way is to quickly cool molten cast-iron in the mould, producing chilled cast iron. Chilling creates a hard skin, sometimes extremely hard. Obnoxious when castings that must be machined later are accidentally cooled too fast at the foundry. And it's not unusual!

This page quotes methods from Machinery's Shop Receipts and Formulas. Published in 1911 when H&S wasn't a major concern and many anti-social chemicals were sold over the counter no questions asked. Typical example:

I have successfully case-hardened cast Iron, using the following receipt: Pulverize and mix together equal weights of saltpeter, prussiate of potash and sal-ammoniac. Make a dipping solution by adding to each quart of cold water 1 ounce prussiate of potash and ½ ounce sal-ammoniac Heat the cast iron pieces till red-hot, roll them in the powder, and then plunge them into the liquid.

Sal-ammoniac is Ammonium Chloride, easily obtained and and prussiate of potash is either yellow Potassium Ferrocyanide, or red Potassium Ferricyanide. Unfortunately Saltpetre is Potassium Nitrate – an explosives precursor, and a bit tricky to buy. I guess the mix hardens cast-iron by Nitriding.

I don't think the process is particularly dangerous, but a controlled chemical is needed and the object has to be brought to red-heat. I'm not aware of a modern equivalent that can be bought off the shelf or prepared at home using ordinary stuff.

I'd put the Machinery's Recipe in the 'possible but impractical for me' category. But someone prepared to flash the cash and jump through the hoops needed to get the chemicals could have a go.

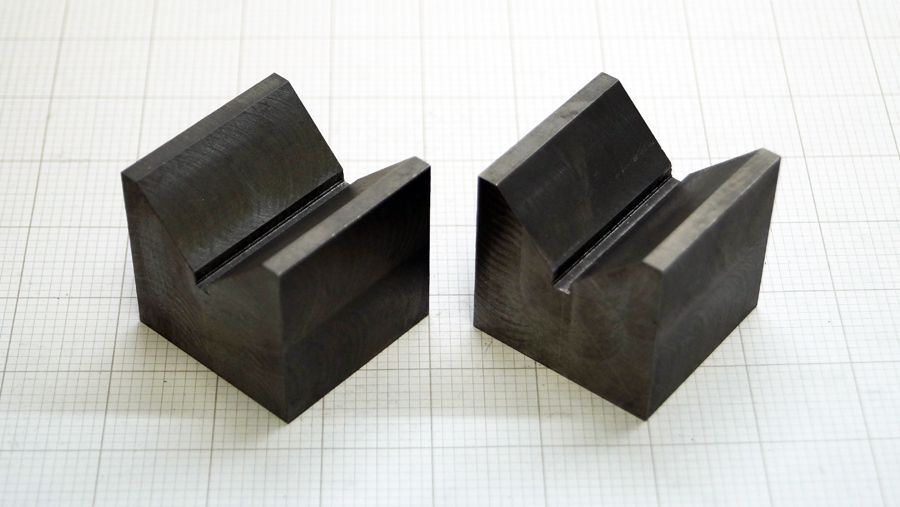

Probably easier to make V blocks out of steel…

Dave

SillyOldDuffer.