Robin, I have a very similar lathe, albeit Axminster branded. It sits on the wonky flagstones of a 200 year old cellar, using eight (four per pillar) 80mm diameter rubber feet on M12 studs (I got them from WDS I think):

I was lucky enough to have to have the generous help of a professional engineer (the late John Stevenson) in setting the machine up. He spent half an hour muttering, twiddling the nuts and checking the ways with a level before announcing 'that's good enough'. No shimming or anything like that, and it was indeed 'good enough' – it turns parallel between centres to < 0.01mm over 400mm. The lathe weighs about 600kg, of which I reckon about 100-120 kg is in the stand and the rest in the machine – so it's the tail wagging the dog – but it seems to work.You'll get there! It won't twist after it's been set up properly – at least mine hasn't.

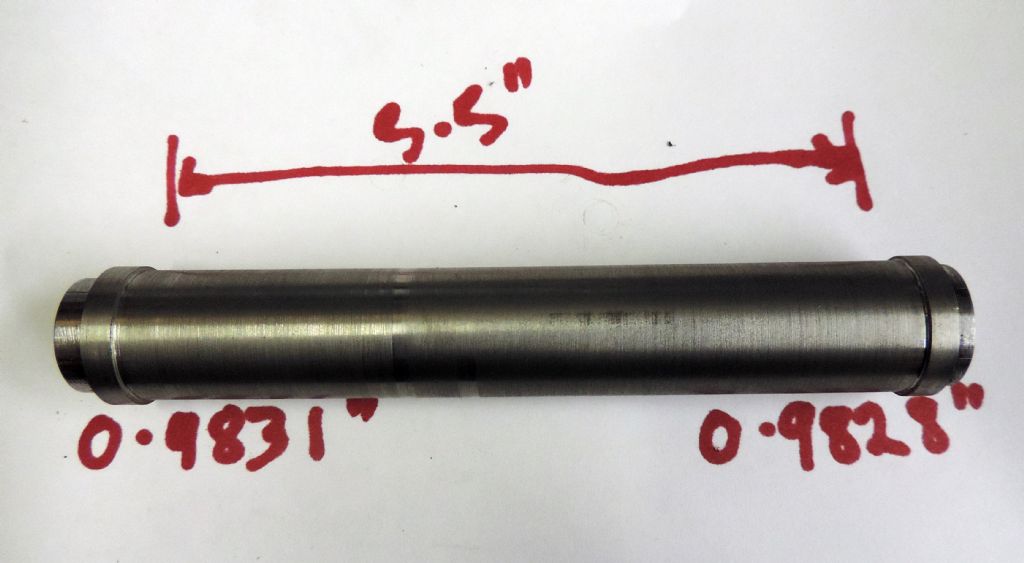

Your method of projecting the spindle axis by holding a piece of what looks like rolled BMS in a 3-jaw is, unfortunately, not good . For starters, the bar cannot be relied on to be round/straight and the chuck won't hold the bar dead on axis anyway. Then there's gravity. You need to think about what exactly you're measuring and why. And re-read what others have said upthread.

Another Robin.

Howard Lewis.

It seems to be improving all by itself but I think it will twist wildly out of shape the moment I stress it.

It seems to be improving all by itself but I think it will twist wildly out of shape the moment I stress it.