To my mind, ChrisH, there are two sorts of saddle stop.

The first is only useful if you are traversing the saddle by hand, and consists of something like the one Neil (Stubmandrel) has shown. On repeated cuts, the saddle bumps up against it, stpping the saddle in the same place each time. For obvious reasons, you can't use it when the saddle is being traversed under power.

The second sort can be used under power, because it either:

(a) cuts off power to the motor when the saddle reaches a predetermined point; this is tricky, because inertia in the motor and spindle may cause problems with repeatability, and trailing wires to switches are needed.

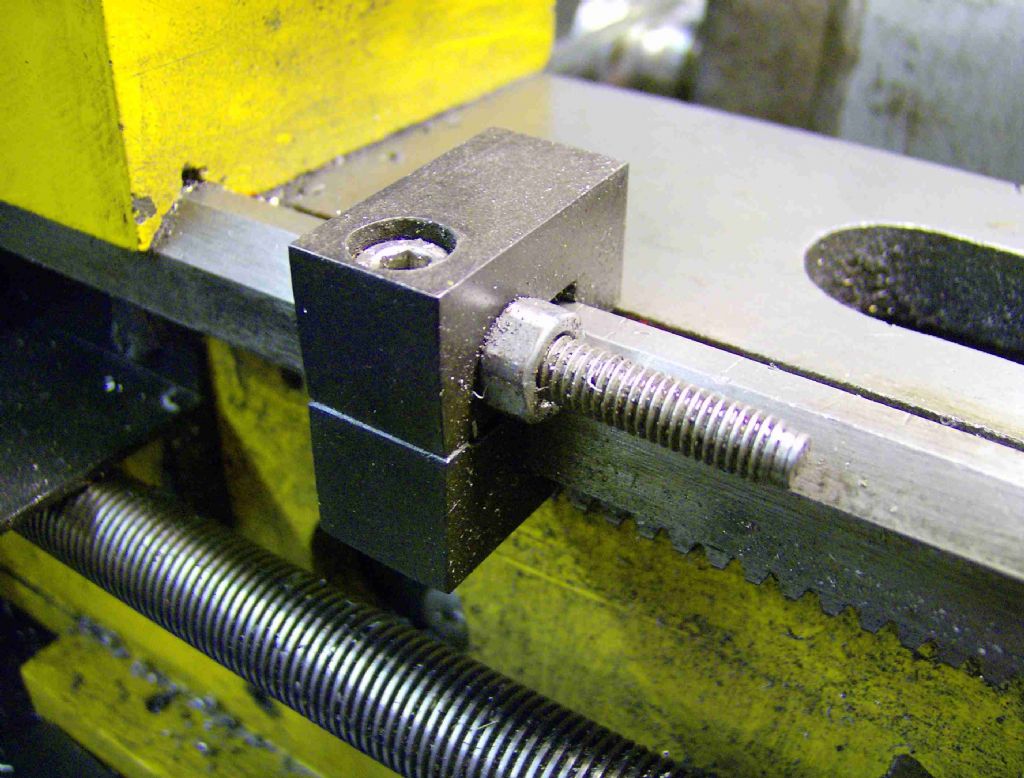

(b) disconnects the power feed by triggering a dog clutch on the leadscrew (as on a Cowells lathe) or by opening the half nuts. I made one which opens the half nuts, which is shown here:

< http://andysmachines.weebly.com/semi-automatic-saddle-stop.html >.

I got the idea from John "GadgetBuilder", though the geography of my lathe meant I could work more in two dimensions than three. His is here:

< http://www.gadgetbuilder.com/ThreadingTools.html#AutoStop >

Andy

michael howarth 1.