+1 for what Hollowpoint says about the Marlco tool. I have one. Excellent device. The Hemingway kit is essentially same design but, I think, a little smaller.

Nice (new) sharp knurls make a huge difference to how well the job goes. I have my doubts about the quality of standard fit knurls on the low end tools. I'd budget for a new set anyway if picking up a used tool. Only takes one bad go on stainless steel to rip the sharp edge right off. Or worse. Got two nicely D shaped ones on my Marlco that way. But I suspect the previous owners had bought on price not performance.

The new ones I got from Zoro seem good despite a more affordable (not cheap tho' price compared to some other pro suppliers.

price compared to some other pro suppliers.

A potential disadvantage of push tools is that the work needs to be stiff enough to stand the strain without bending.

The hand held nutcracker type are quite easily made and surprisingly effective on normal jobs. Not for stainless tho'.

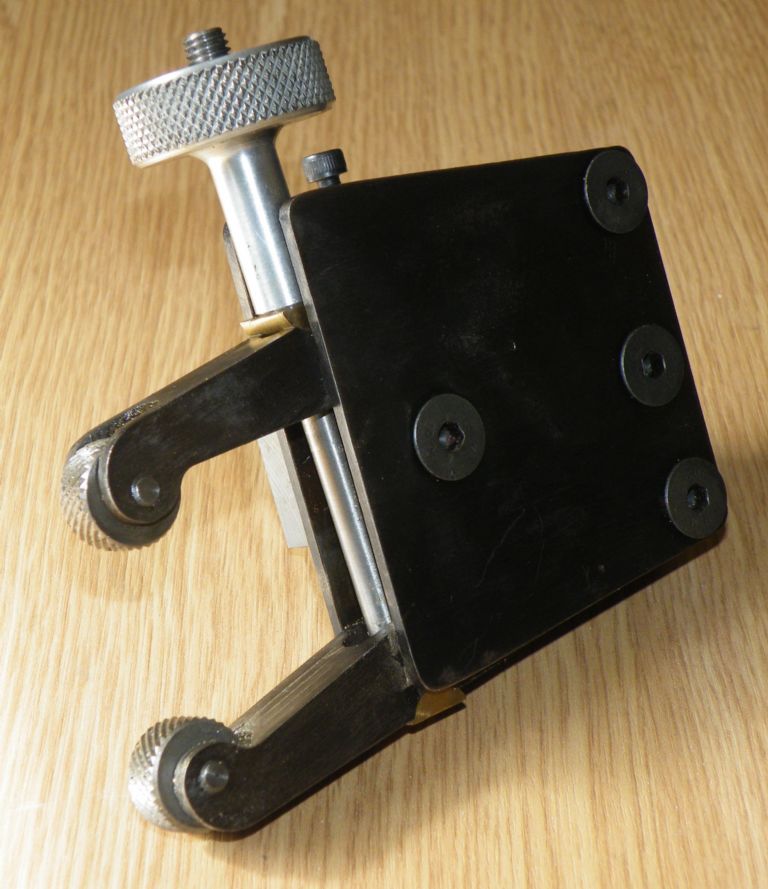

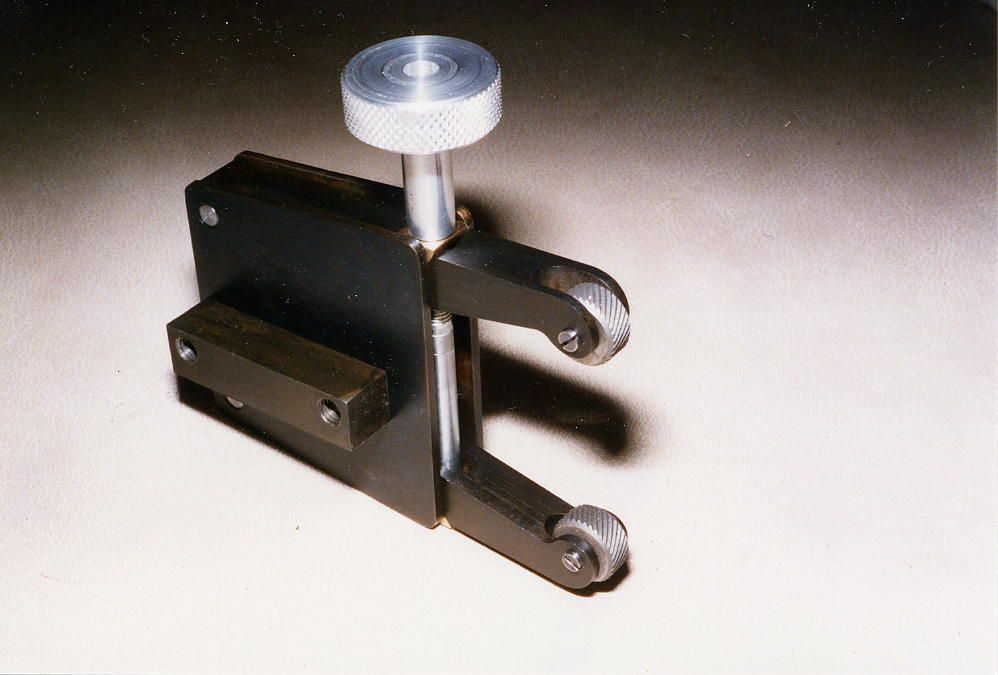

This is mine, a proper commercial product.

The design has been replicated for a Model Engineer article published 29 th January 1999.

American Magazine Popular Science for October 1941 has brief DIY details for a very similar one **LINK** or Google for Nutcracker Knurling Tool.

Also one in May 1965 edition of the American Practical Mechanics magazine **LINK**. Somewhat larger I think.

Clive

Edited By Clive Foster on 11/05/2020 13:28:10

KWIL.

price compared to some other pro suppliers.

price compared to some other pro suppliers.