It may be a lever lock, but to me looks more like a pin-type cylinder lock.

If so, there are two basic types.

In the first, as I think this is, when the key is inserted fully in the cylinder whose tail operates the bolt, each tooth and gap moves a pair of pins in a radial hole, to align the unconnected joint between them with the internal surfaces of the lock body and cylinder, allowing the latter to rotate with the key. The pin ends are rounded or chamfered to ease them across the edge of the hole.

When the key is withdrawn, a spring above each pin pair returns the pins so one of each pair straddles the boundary, keying (in a shaft and wheel sense) the cylinder rigidly to the body.

If I am right about the lock type here, examining the flat along the top of the lock may reveal the pressed-in sealing plugs that retain each spring and pin pair.

(Why a pair of pins, not just a single pin? A lock with single pins would need a key that simply puts the base of each in line with the lock wall – not secure against a fluted strip of constant width beyond the initial ramp. Using two pins ensures that over-height key teeth would make the lower pins straddle the boundary.)

'

In the second , as used to be used on cars , filing-cabinets and the like, the pins are replaced by thin plates; but I am not sure if they work as in the pin type or by emerging to pull an outer cylinder round with the inner, holding the key.

'

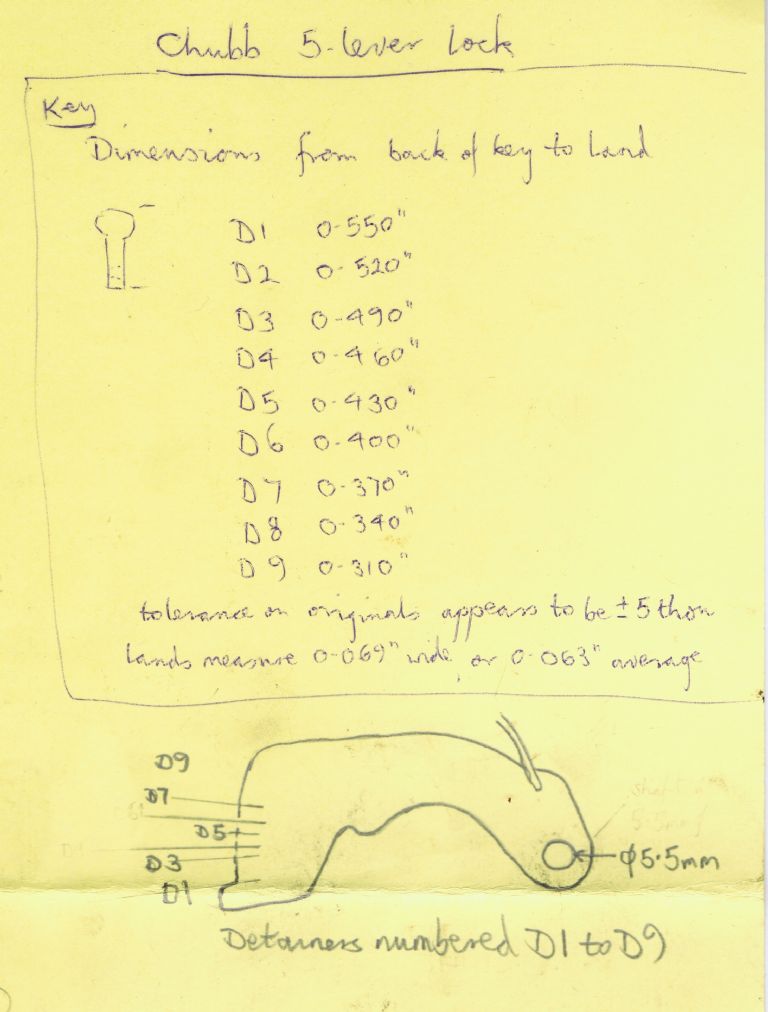

I would think if this one does use levers, the principle is essentially the same – but if so you need know the true lift of each lever, as with the pins. I am not surprised you can't find the dimensions on line – it's not something that reputable lock-makers and repairers are likely to publish, for obvious reasons.

You are better off simply buying a new lock and keys. The tolerances on locks and keys are close and though no doubt feasible for your milling, the combinations of dimensions make it hard to know the real dimensions from a badly-worn key, and if the lock is worn as well, the chances of success are even lower.

Places like Toolstation and Screwfix are probably open but by on-line or telephone order preference, and collection at doorway, as in Lock-down 1 last Spring.

'

I have made a key for a pin-in-cylinder padlock whose proper keys were long-lost, by filing a brass-sheet blank to shape (flutes as well). It was a right faff, and more a challenge than a serious proposition. I could do it thanks only to my having read a description of the principle, many years previously!

To measure the key, I polished the lock side (between the curved flanks) to see the brass sealing-plugs against the surrounding brass. The plugs were about 3-4mm diameter, so by very carefully drilling and tapping each M2 I could withdraw them by screw and spacer.

Once I'd laid out each pin pair, spring and plug in order, it was head-scratching time to work out what I had actually to measure and calculate for the pin travels, along with their pitch, cylinder diameter and fluting.

I had no milling-machine at the time. It was all file work. Having filed the flutes so the rectangular blank could enter the stripped cylinder, I profiled each hill and dale, starting I think at the inner end, to make its associated pin-pair rise to the correct altitude. This was with the lock all open so I could measure the depths in progress.

It took a long time, a bit at a time over days, but eventually I had the key work and I could re-seal the pins and springs into their bores.

Was it worth it?

Frankly, no; not least because the one, home-made key would be difficult if not impossible to copy properly on a standard blank in a commercial key-cutting machine. It was a good-quality lock, and I had originally asked a locksmith if he could make new keys. He replied that yes he could, but at a cost far above that of a new lock and pair of keys of similar type and quality. Hence my DIY attempt.

I still have it somewhere but dare not use it, with only one, hand-filed key!

= = =

I digression… One of the simplest but most secure locks I have encountered is a "special", on an equally special door. It consists of a large, stainless-steel screw with a head profiled to fit the unique set of 2 or 3 keys that were made, working inside a long steel tube to engage a hole in the frame; the lot being of welded steel. The lock is reached via a hand-hole in the door, and the screw-head is deep within the tube, so nothing is visible even as a clue from outside. I know it because I profiled the head to fit the key.

Peter Cook 6.