Posted by Bazyle on 29/08/2019 13:18:09:…

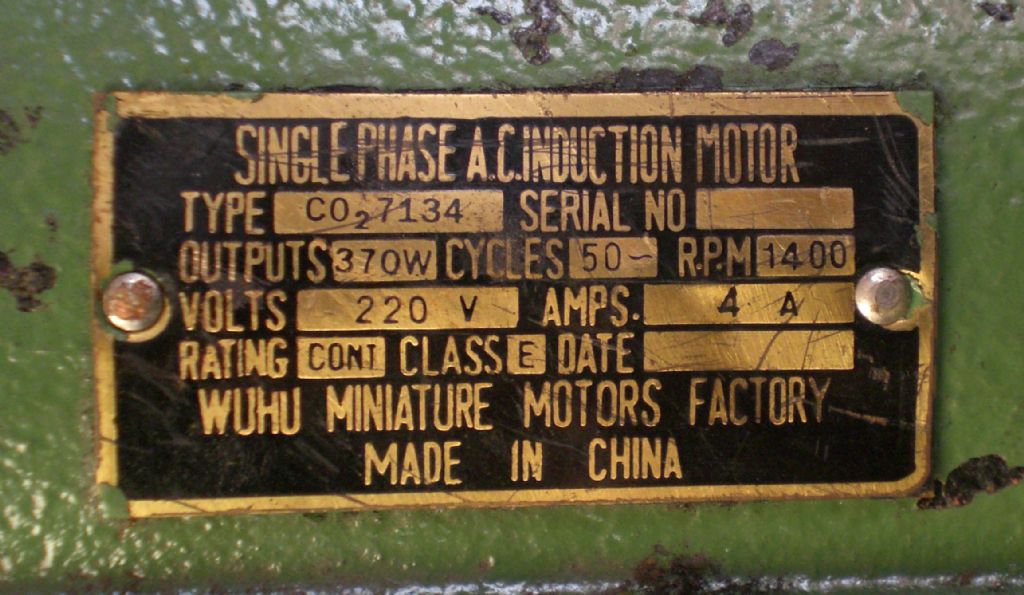

Rating plates can be misleading…

Very true! The numbers given in adverts lack all the detail needed to give more than a rough idea of a motor's performance. While rating plates are much more useful, they too fail to provide the data needed to really understand how good or bad a motor actually is.

To get that information, you need some kind person to measure the motor's behaviour over it's operating range on a dynamometer. This results in a graph that discourages advertising gloss. Manufacturers seem reluctant to publish performance graphs; presumably they think ordinary consumers don't need to know. (Which is probably true.)

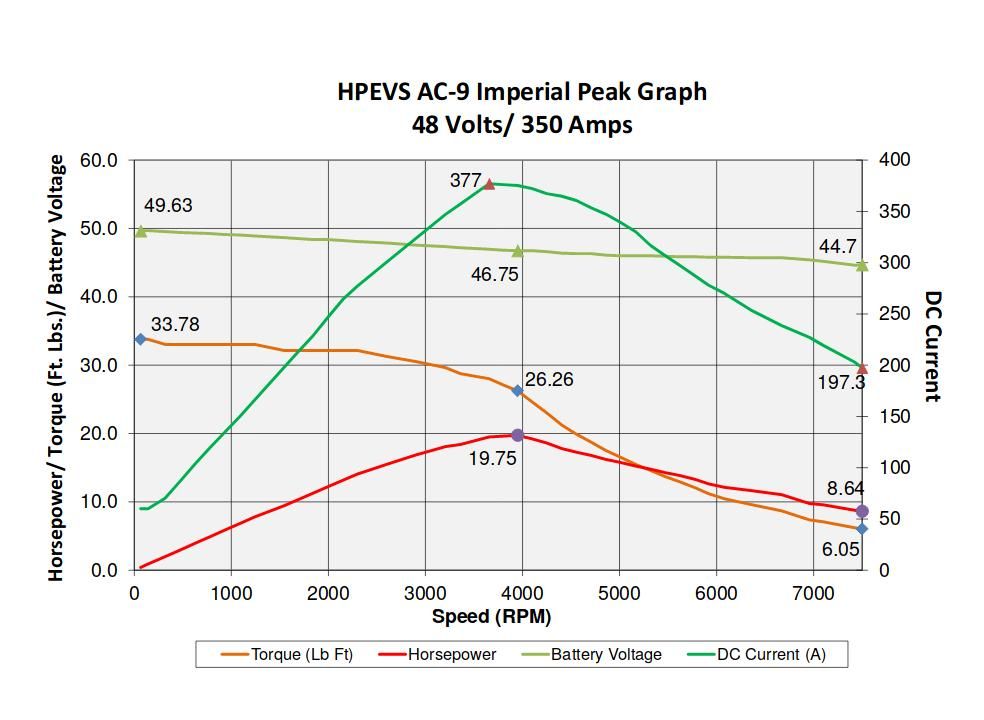

However, this seller does provide Performance Graphs from which I pinched this example, a golf-cart motor:

As can be seen, the graph shows the performance of the motor varies considerably. Torque tends to drop as the Power Output rises. Peak power output occurs at about 4000rpm. Current and power output are related but do not track exactly. Although efficiency isn't measured directly, it can be inferred that motor efficiency peaks between 3500 and 4000rpm, and while running the motor slow reduces efficiency, running it much faster is even worse.

One important fact not captured in this example is temperature. Although far more informative than a few numbers stamped on a plate the graph gives no clue as to whether this particular motor is continuously or intermittently rated. As the motor is intended for a golf-cart, I guess it's intermittently rated, perhaps 60 to 80%. It's probably expected to work hard pulling a couple of chubby golfers between holes but then has several minutes to cool while they putt and tee off. Nor is there any information about vibration or expected life.

A great deal depends on the type of motor too. The AC/DC motors used on old sewing machines behave very differently from a 3-phase motor on a lathe, which is different again from a brushless motor. Perhaps the worst electric motors are the single-phase types but even they do a decent enough job as proved by many satisfied Myford owners.

Fortunately it can be assumed most motors operated in their comfort zone will be – very roughly – about 80% efficient. Big motors tend to be more efficient than small ones and modern motors are usually better than older ones. This is partly because designs are better optimised and partly because superior materials are available. Superior materials can mislead. Improved insulation means motors are run a lot hotter than was possible before. You can't just stick your hand on a new motor and decide it's too hot. It might run hot by design and heat need not mean the motor is inefficient.

Or it could be faulty. Magic smoke is always bad news…

Dave

SillyOldDuffer.