Posted by Nicholas Wheeler 1 on 27/10/2021 10:35:50:

How much material do you need to remove to produce your edge? That, and how many parts are needed would be the biggest factors in deciding what tool I would use to do the job. Your small production run of 64 instantly elevates it to a machine job for me. 64 parts is not a small run for a home shop! And I wouldn't have finalised the design until I had proven methods for producing all of the parts

You keep writing you want to grind the edge with your whetstone, and I think that's what is causing some of the problems; whetstones are for refining an already created edge, not roughing them out from a blank.

A) Amount of material to remove

The amount of material I need to remove, depends purely on the skill and accuracy of my cutting the steel sheet by hand, but I would guess between 1 and 2 mm would be a reasonable amount to have to remove. Although if I have my (heavy beast of a) disk sander out could quickly reduce that to 0.5 to 1mm to remove.

To get clear, yes clearly I would not make x64 parts before 'finalising' the design (as best one ever can in these situations).

[Obviously if I am making larger numbers and if the design seems finalised, then I would consider getting someone to laser-cut them, but typically there would be a £60 to 100 setup cost plus 5 to 10 days of delay to factor in… and even then I would still need to get them cleaned-up/resurfaced/deburred and filleted to make sure that they aren't to sharp. ]

B) Machining

I'll have another got at using my Proxxon MF70 after my new parallel steels arrive.

C) Using a whetstone

> whetstones are for refining an already created edge, not roughing them out from a blank.

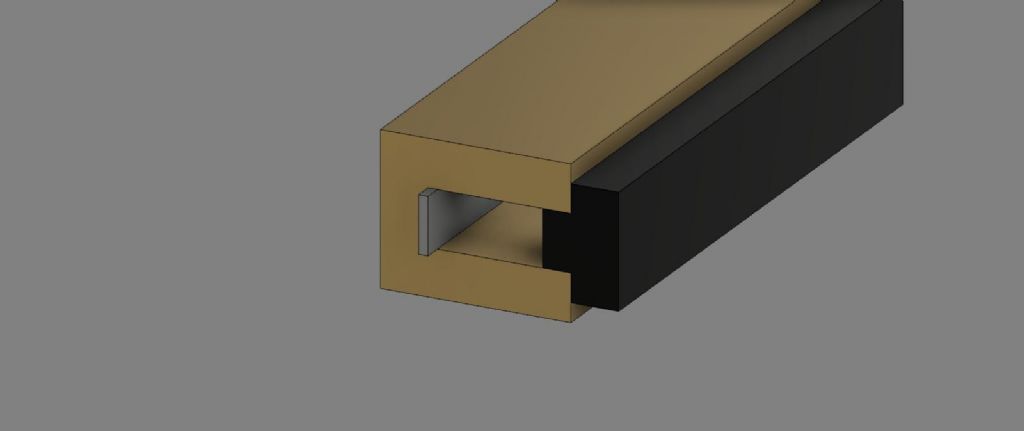

Yes exactly. It's just that I want to keep the face on each cut edge at exactly the correct angle (in this case 90° whilst I refine its surface, and a long a narrow (1mm) surface that is rather tricky.

whilst I refine its surface, and a long a narrow (1mm) surface that is rather tricky.

Btw, yes I have tried sticking them a number of them together with double-sided tape. This definitely helps maintain accuracy but it's rather time consuming to add the tape, accurately stick them together, remove, clean up etc… (plus I keep running out of d/s tape!)

FYI, the reason why I do need such accuracy is because the magnetic pull between two mating surfaces which have been magnetised is dramatically affected by the closeness of the fit.

i.e. If the surfaces do fit together well, then the magnetic pull will increase dramatically and both a much smaller, cheaper, lighter magnet can be used, together with smaller/cheaper/lighter steels.Yes, I have some Kapton tape somewhere. Good suggestion. Although as I recall it bonds almost too well. What would you normally use to remove it – Isopropanol/Acetone? (I have both).

D) Dykem

Is there anything special about Dykem's layout blue? At c. £15/bottle it's not exactly cheap. Mind you a Jumbo Edding 850 Permanent Marker Pen is c. £9.25, and probably contains a lot less fluid…

– How long does it take to dry?

– How do you remove it?

– How bad are the solvent smells?

Thank you for all your thoughts

More later.

K

Edited By John Smith 47 on 27/10/2021 12:53:32

John Smith 47.

whilst I refine its surface, and a long a narrow (1mm) surface that is rather tricky.

whilst I refine its surface, and a long a narrow (1mm) surface that is rather tricky.