Posted by Plasma on 22/03/2019 05:53:15:

…

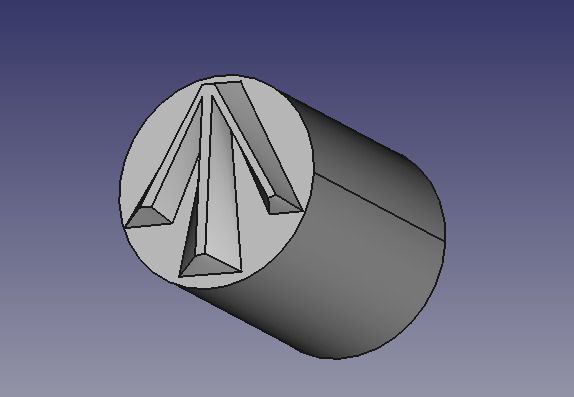

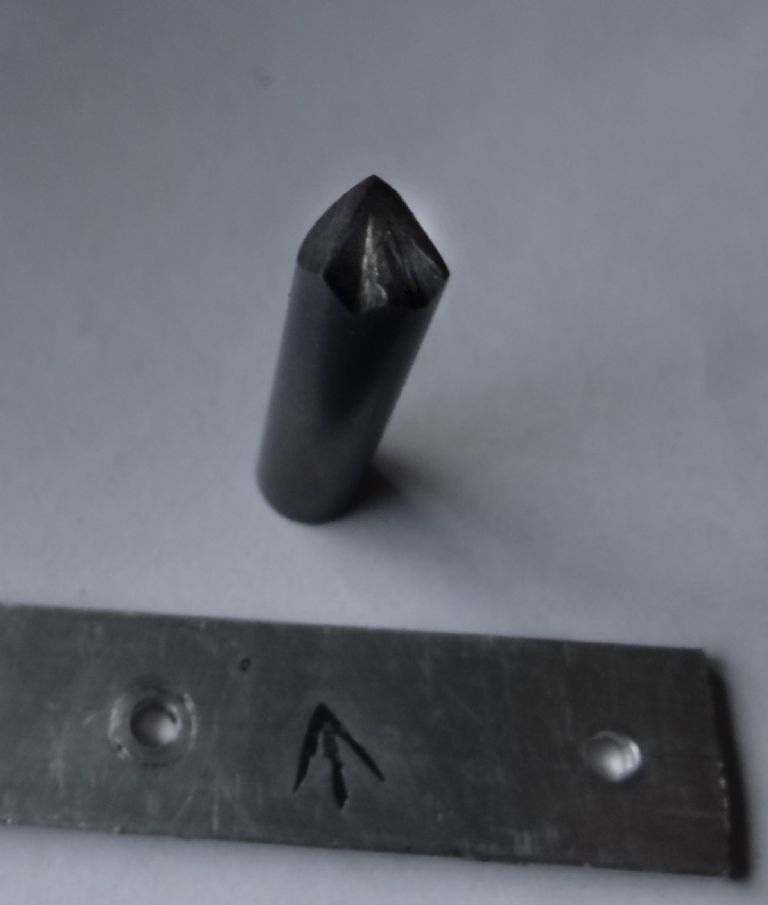

One nice tip for finishing a punch marked item is to flood the mark with silver solder and the file it back to flat so the mark becomes a bright print rather than a dark indent.

Best regards Mick

This sort of advice is why the forum is so valuable: I would never have thought of that!

I guess the forum delivers due to its attracting a wide range of technical interests. Everything from fine knifes and clockmaking to traction engines and blacksmithery, via astronomy, gun-smithing, amateur radio, CAD, CNC, microcontrollers and a dozen other technologies! Lots to learn from each other.

I wonder if anyone knows how to replace the black filling in the engraved graduations of steel-rules? I have several hard to read rules where the original filling is all but gone. The problem seems to be finding a paint thick enough to stick in the hollows while remaining thin enough to wipe cleanly from the plain surface. The various inks, paints and waxes I've tried either stick firmly to everything or wipe off leaving nothing behind in the graduations. Boot-polish works but it soon wears off.

Ta,

Dave

Edited By SillyOldDuffer on 22/03/2019 10:38:25

BETTY HUNT.