Posted by JasonB on 05/08/2018 15:42:55:

You can take that blade out of the holder and put it straight in the toolpost, thin strip of metal between blade and screw will help

Thanks Jason.. Do I have to Shim the side out first so it actually reaches the screws?

Posted by Michael Gilligan on 05/08/2018 16:12:11:

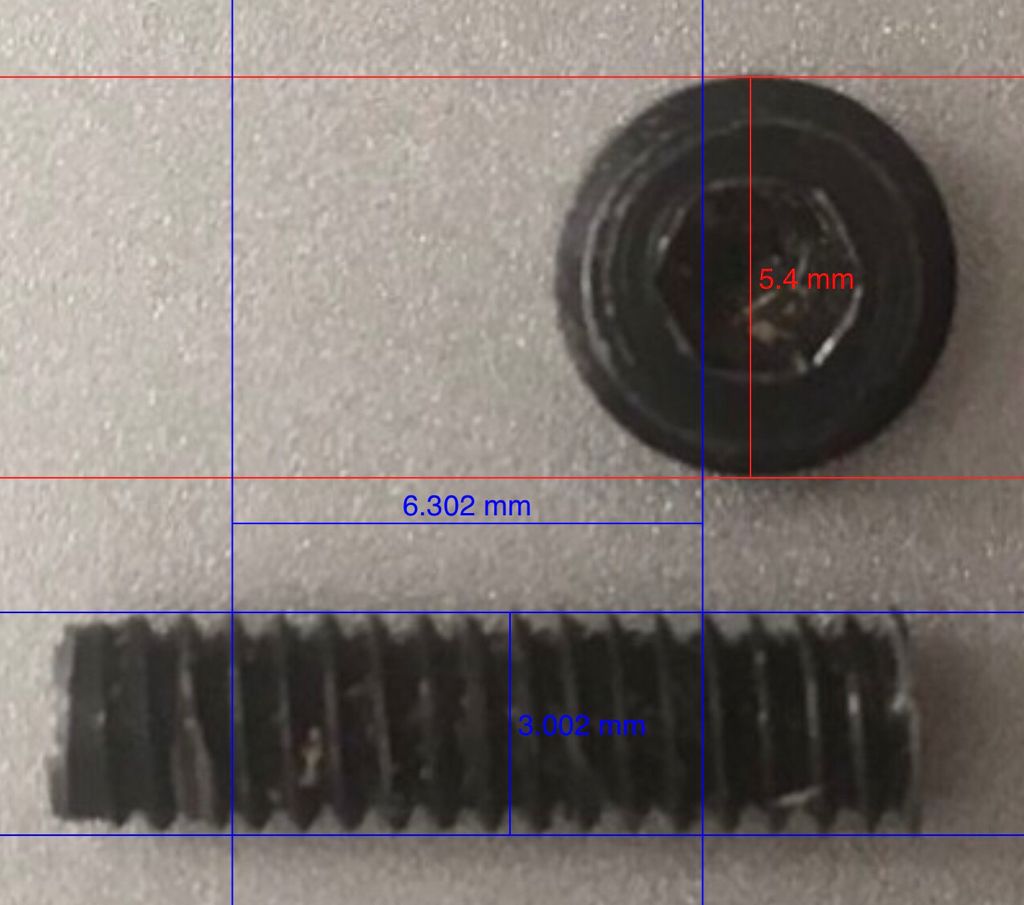

Going by your photo … Yes that is a metric screw: The proportions of the heads differ noticeably between Metric and Imperial.

If it's M3 then the socket should be 2.5mm a/f … So I guess you were using a 3/32" a/f wrench.

Yes I was indeed using a 3/32 the 2.5mm allen key definitely didn’t fit, I just double checked to make sure.

Posted by Frances IoM on 05/08/2018 16:31:00:

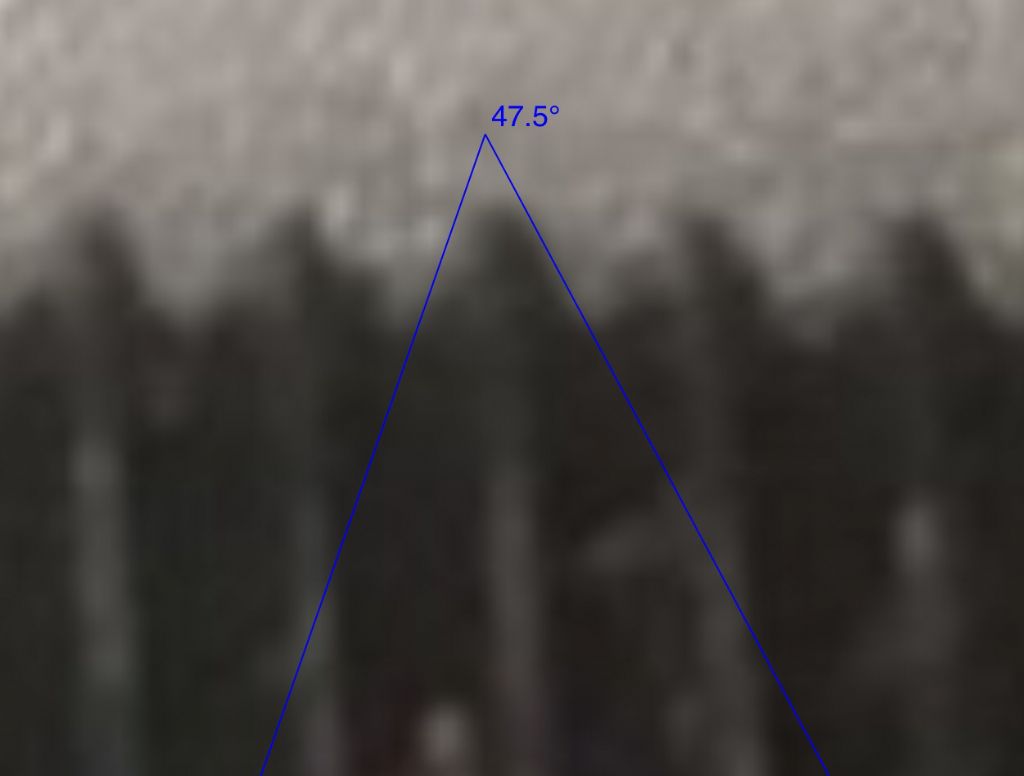

how on earth did you take the head off a cap head screw ? normally the thread will give way – anyway sounds as though a thread gauge can be added to your shopping list – 3mm Iso coarse are 0.6 mm thread; also suggest that if you do buy a grinder (+ safety goggles) you move away from the kitchen table to do any grinding.

I honestly think it was a really poor screw from looking how it broke off. It left me with a donut shaped cap with the threaded part all in one peice. Having rebuilt a lfew engines I generally have a good feel for fasteners but this was like cheese. Yes, good tip about the grinder, I would definitely get a sore ear for that on the table if nothing else!

Edited By Steve Sherlock on 05/08/2018 16:48:28

Howard Lewis.