Hi Dave,

Almost but the clamping bolt that holds the two parts together is slackened after the main big clamping bolt and then the rear dowel is pulled out. Then offset the tailstock by sliding it sideways and nip up the bottom bolt and then the main bed clamping bolt.

The tailstock parallel slide is a very good fit inside the top shears so it has true alignment with the bed. You will notice that the headstock sits on a flat surface so it can rotate on the pivot bolt. Unlike the ML7 and S7 which has a similar arrangement to the tailstock. Also on the ML7R / S7 there are pusher screws at the headstock end to align the headstock by a tiny amount. These screws are the same ones as the tailstock uses for offsetting.

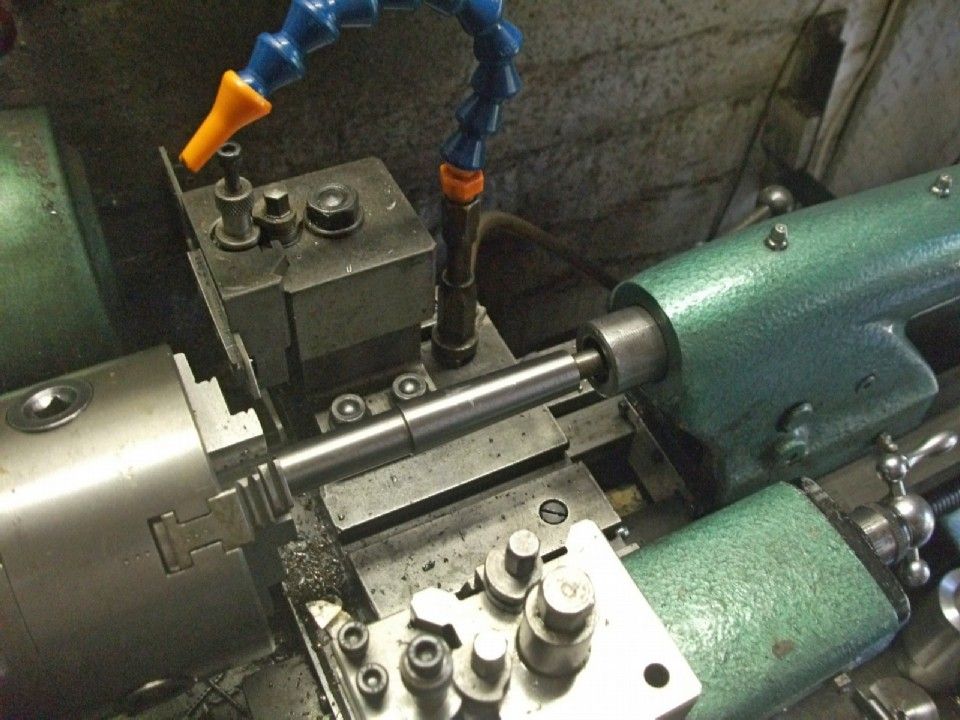

There is one weakness on the Grayson tailstock which is the barrel locking screw. This often breaks the casting and it is very difficult to weld the cast iron pieces back together. Mine has this broken part and I have never bothered to get it repaired as the S7 came along at the right price.

On early ML7 lathes the bed was different to the later ML7R and the Super 7. When Myford brought out the Super 7 they scrapped the early bed design and the ML7R and the Super 7 used the new bed design. It has wider top shears to better cope with the higher cutting loads. Also they eliminated the internal bed slideways, that is why the internal slideways on the later versions have a gap between the internal slides and the bed top shear, it was redundant but they used up the earlier castings until new ones were introduced.

There wasn't much difference between the ML7R and the Super 7, the Super 7 was a rich mans version and it had the countershaft clutch, better vernier dials, a longer cross slide and a few other twiddly bits which the cheaper ML7R didn't get. By standardising on parts you can retrofit a ML7R to Super 7 specifications quite easily. The main difference is the headstock design. The Super 7 has the newer spindle with the taper bronze front bush and the two angular contact rear ball bearings to control end float. In the end the ML7R and the Super 7 became almost the same machine and the cost of the ML7R became too high as for not much extra you could buy the S7 version, so Myford dropped the ML7R and continued with the S7 version.

On my Grayson I made a long cross slide as per the Super 7 by hacking it out of a piece of steel with my (then) new vertical milling machine. I bought the new cross slide handle and nut assy from Myford and it made a big difference to working on the lathe.

On my Grayson the headstock is missing. I was going to make new front and rear bearings as per the S7 and sent it to a local company to do the machining. After a few months of not hearing anything from them I found out that they had folded and the liquidators had come in a cleaned out all the stuff, including my partially modified headstock and the chuck backplate from a new 4-jaw chuck I had loaned them as a gauge to cut the front register and thread. So my Grayson is sans headstock and the 4-jaw chuck is minus its backplate  Seems it was sold for scrap to raise some funds. I still have all the other bits but without a headstock it is just quietly gathering dust.

Seems it was sold for scrap to raise some funds. I still have all the other bits but without a headstock it is just quietly gathering dust.

Edited By John Fielding on 26/02/2016 08:12:19

Keith Long.

Seems it was sold for scrap to raise some funds. I still have all the other bits but without a headstock it is just quietly gathering dust.

Seems it was sold for scrap to raise some funds. I still have all the other bits but without a headstock it is just quietly gathering dust.