Hi Everyone!

Once again, thanks for the interest in My thread, it is really great to recieve such sound and useful advice!

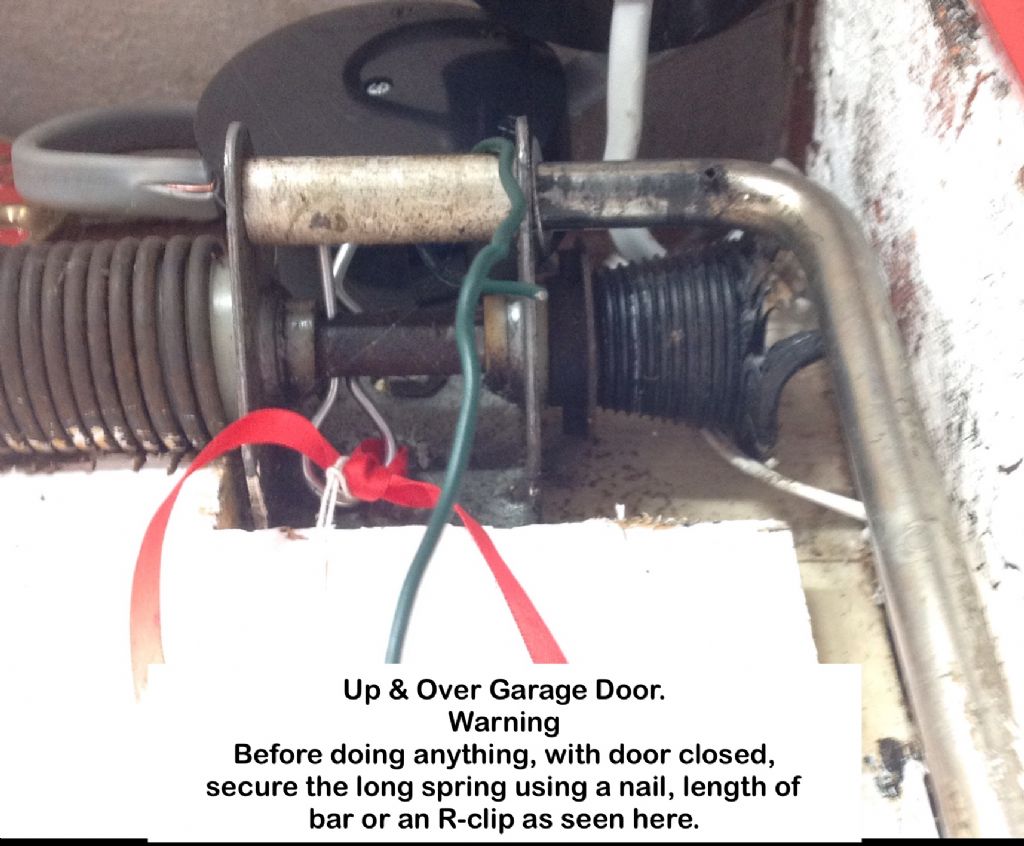

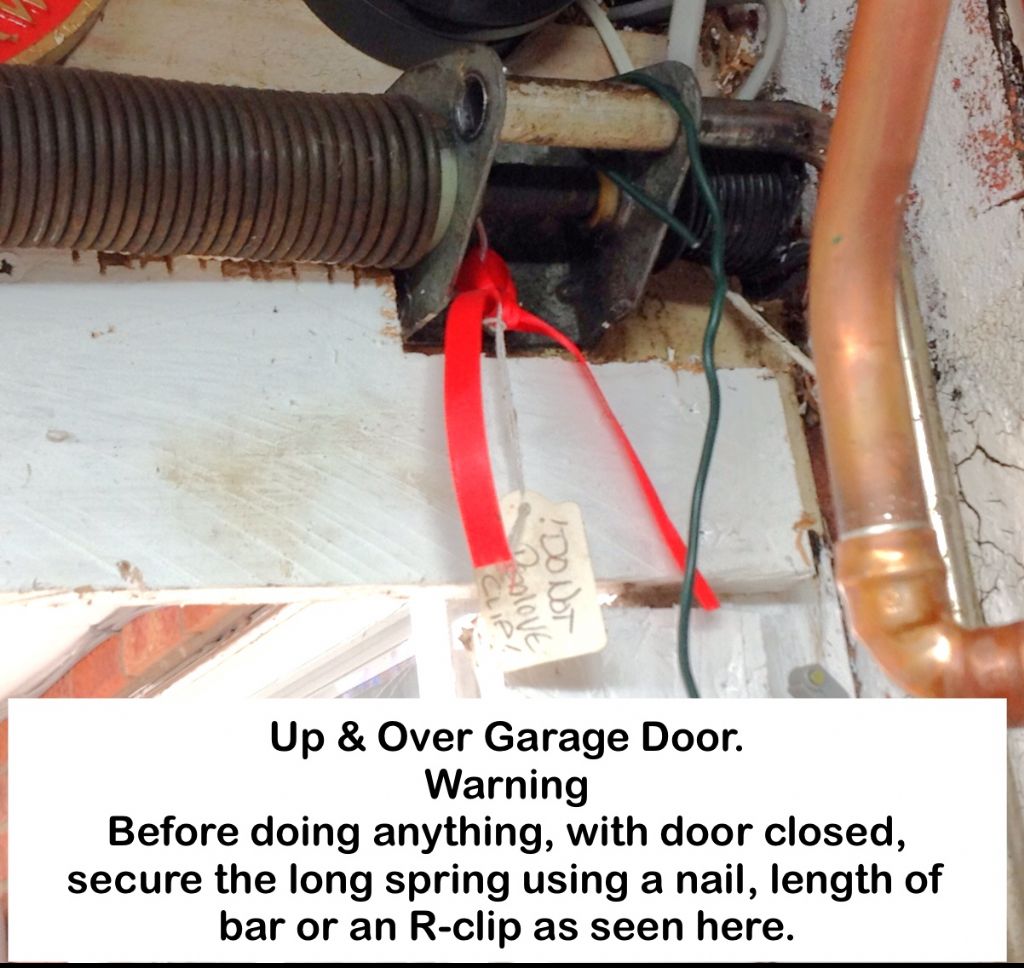

Geoff, thanks for the warning about the door springs, I fitted this door as a replacement many Years ago so I was aware of potential dangers, but thanks anyway!

John H :- Noted !

!

I omitted to mention that We unfortunately have a shared drive, which consequently entails parking My car tight up against the garage door to allow the neighbour access to Their parking space, this was the reason for fitting a side entrance door to save having to move the car to access the garage (the car has to be moved onto the road,if I can find a space anywhere!)

So Basically, the main garage door is rarely used, it was opened a couple of weeks ago to get My lathe in, the last time it was opened was to paint it, seven years ago!!

The only other large piece of equipment left to come in will be a mill, I thinking table top,at the most a Centec 2, which will be pulled in before any door alterations take place.

As for projects,I think stationary engines and large static veteren vehicles (up to 1/8 scale ) will be My maximum, so not a problem there.

Looking outwards from the garage,I really think a 'U' shaped layout will work best for Me, with a bench across the garage doorway, lathe to my left, mill maybe on the bench in left-hand the corner at 45deg, Bench in front of Me with vice on right hand side, then the entrance door and finally,on My right,the grinder and hot work bench.

Cupboards under the long bench will take care of tooling stoage, plus My Lathe (Super 7) is on a Myford stand,so storage in there too, plus there will be room above the lathe for shelving or shadow boards for lightweight storage.

The roof above the working area will be insulated and panelled off,at the far end of the garage left open for roof storage of long stock items.I hav'nt got a scrap bin,not made any(yet!)

We are not planning on moving in the future,but I know things can change,so everything I'm thinking of doing (including a full upvc panel with top window),could be reversed if necessary.

Howard. duckboards were My thought too,or rubber matting(found a relatively cheap supply on Ebay,thought of lining the cupboard shelves as well)

As for lighting, I'm thinking 3x 5' tube fittings. plus lamps for the machines will give Me what I need.

Andrew:-

I did have a look online as to planning considerations,two things I found were if a brick wall were used,additional footings could be required, not a problem with a upvc unit, the other thing was loss of car parking space,not an issue because We have never had a car in it! But I will check before moving forward.

Once again,many good ideas to consider, I know that setting up a workshop is always a 'work in progress', but planning as much as possible in advance is always a good idea!

Again, many thanks to Everybody for their help and advice, I am overwhelmed by the helpfulness and friendliness of Your responses!

Cheers, Pete

Edited By Morty on 25/05/2019 18:54:23

Edited By Morty on 25/05/2019 18:56:12

Samsaranda.