I like it, especially the graphic identifying A,B,C,D on the banjo.

Nit picky suggestions:

If source and warranty are considered important, I suggest a hyperlink or button rather than 'View Source', because the latter is too techie for most. Anyone knowledgeable enough to want to look at the source can crack that on their own, but the Warranty should be as simple to find as possible.

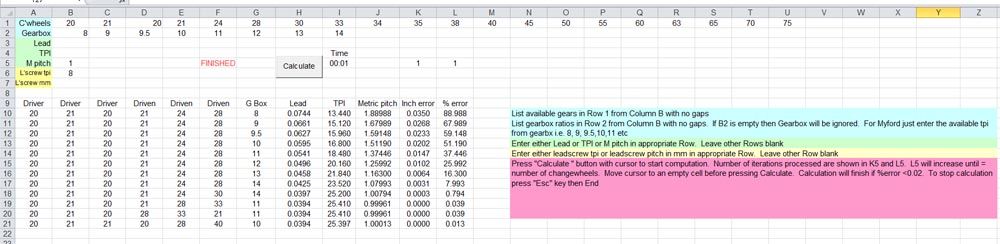

As all up to date engineers are metric (discuss!), I'd prefer a natural metric interface rather than converting to TPI. Perhaps a button that switches between TPI and pitch?

Mildly useful if the table had columns showing actual TPI and pitch as well.

Advanced topic: not all gear combinations will fit on the banjo, and it would be good to highlight potential time-wasters. For example, one of the solutions for 12tpi is 35 80 60 70 which engages two large diameter wheels. To identify misfits the maths would have to compare relative diameters derived from the number of teeth. I think it's possible but could be wrong!

Bugs/Features:

Gear sets containing duplicate gears tabulate duplicate results. Try 20, 25, 25, 30, 35, 40, 45, 50, 55, 60, 63, 65, 70, 75, 80, 85. Duplicate results should be removed from the table.

Take a gold star Calum – nice work.

Dave

PS Gold star for Hairy Pete too. Is this like buses? You wait 3 hours in the rain and then 3 turn up together!

Edited By SillyOldDuffer on 19/07/2021 14:08:06

Roderick Jenkins.

Roderick Jenkins.