Coming back to the original question – the "what" rather than the "why" – and always a difficult thing on a forum!

I bought one of these levels (the 200mm version) a few weeks ago. I was also concerned about the "bit of rust" comment but mine was clean, no rust apparent. What was a problem was that the bubble had fallen out! The thing comes in a fitted case with a bit of foam packing, and was well wrapped in bubble wrap, but had probably been dropped or thrown in transit. The bubble assembly – the vial – is plastic, and it's glued into a piece of channel section pivoted at one end and bearing on a spring-loaded adjuster screw at the other. The glue had given way and the vial was loose. I fixed it back with a bit of PVA glue (my thinking was strong enough to hold it, weak enough that I could remove it if necessary). I tweaked it on my carefully shimmed surface plate so that it read the same when turned end-for-end, and it seems to be holding its calibration fairly well. I cannot detect any rock on my surface plate (a 300x300x20 slab of plate glass). This is not Moore and Wright, Hilger, etc, quality but it works. If I put my thinnest feeler gauge under one end, the bubble moves the number of divisions that I would expect. Again, not metrology lab standards, but a reasonable sanity check.

I bought it to help align the profile rails on a CNC router that I am building. It's a welded steel structure with steel box sections about 1800mm long carrying the rails, and due to manufacturing and welding distortions, there was a dip in the middle of roughly 1.5mm. I used an epoxy bed to get close to level, bolted down the rail, then used the "precision" level (with feelers as necessary) to measure height differences every 200mm. I'm assuming that this was fairly accurate as I found a +-0.1mm variation; after inserting the calculated shim thickness and remeasuring I was within about 0.05mm which is more than good enough for this job.

So, as a level it's not the best in the world, but it's certainly not the most expensive either. You get what you pay for, it does the job, and even with the Christmas post, I ordered it one day and it arrived the next.

ianj.

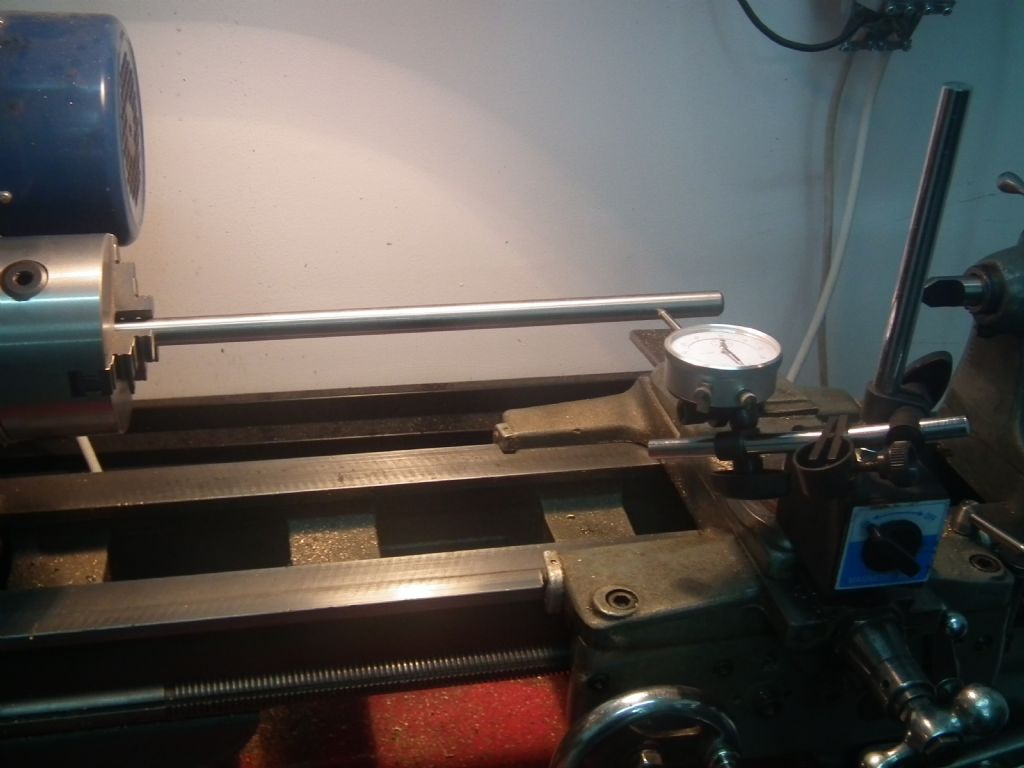

to get the machine to cut parallel to within 1/10 of a thou over 10" which in my book is very good.

to get the machine to cut parallel to within 1/10 of a thou over 10" which in my book is very good.