Well I needed to machine down a bit of brass to a smaller size and just so happened to have one of the same DT cutters from ARC as part of the pile of stuff Ketan sent me for the articles so thought I would see what it cut like.

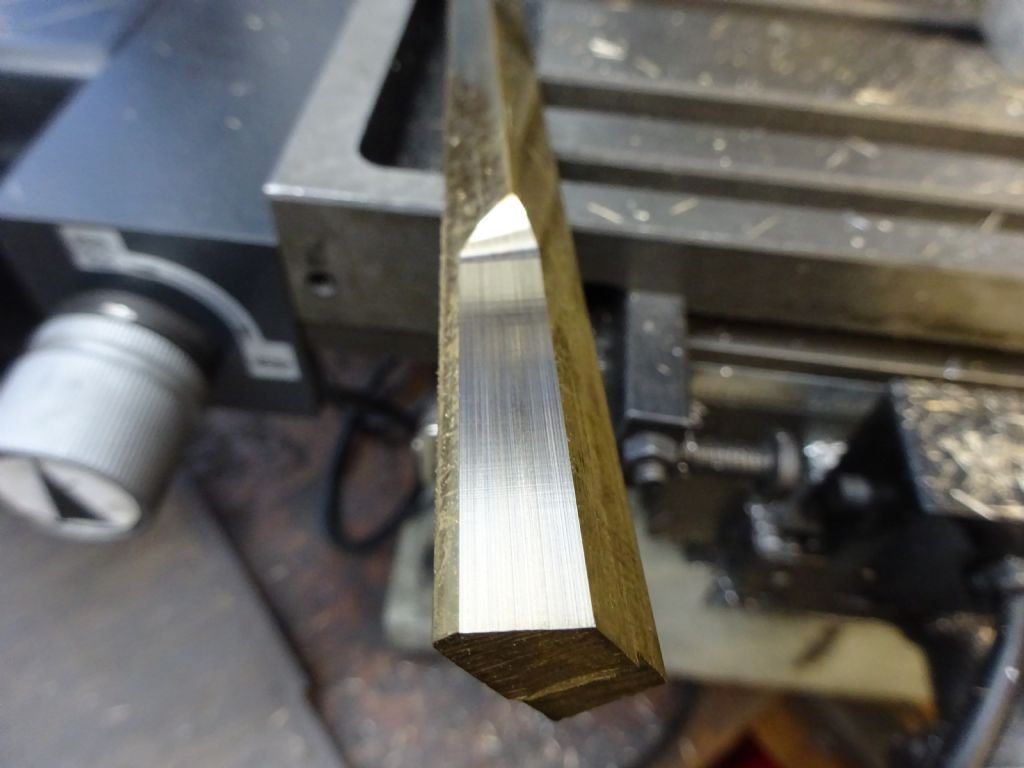

Brass is 5/8 x 3/8 and I just popped it in the chuck with a little over 2" sticking out, would support better if it were an actual Gib I was making.

Cutter is about 8mm high so I set the large dia just below the bottom of the bar so say 7.5mm vertical height of cut. Decided to take a decent cut and do it all in one so at the bottom the depth of cut was 4.3mm

Would up the vari speed to what sounded about right maybe a bit on the fast side to what I would normally have gone for. I later got the laser tacho out and was actually running at 1560rpm

Started up the mill and wound it in by hand as I assumed Martin does not have power feed, counting the turns I would say I was going a bit faster than 1 turn per sec so that would give a feed of 7-8" per min and I think it would easily have taken faster but may have been pushing it at 600mm/min maybe 300mm/min would have be max on my machine.

Some visible lines along the work but could not detect them with a finger nail and likely just down to the grind of a hobby priced cutter, very minimal marks across the work which could be down to speed of feed or not the best support to the work. There was no noticable metal removed as the work was would back to the start of the cut so that would also indicate minimal deflection due to a blunt cutter.

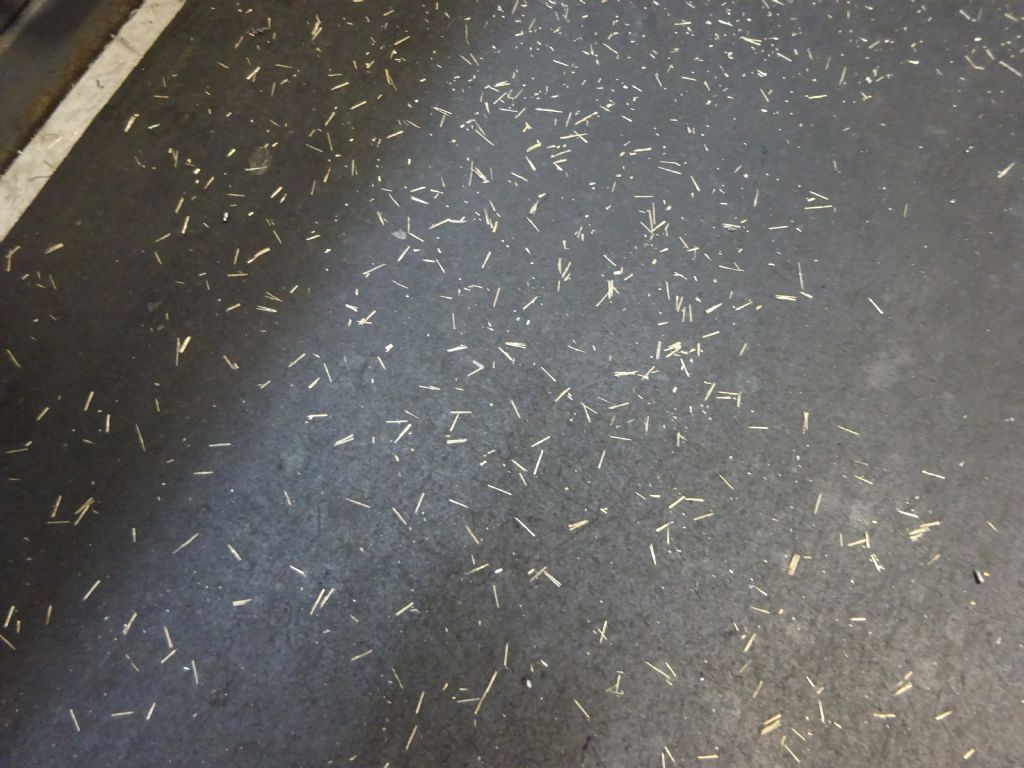

Swarf was nice little needles not dust that you get with too small a tooth loading.

machine is a 10yr old Sieg X3 with original gibs and I can't remember when I last adjusted them but over a year ago and my machine does get used.

J

Martin Shaw 1.