Posted by john fletcher 1 on 24/12/2017 17:44:45:

…

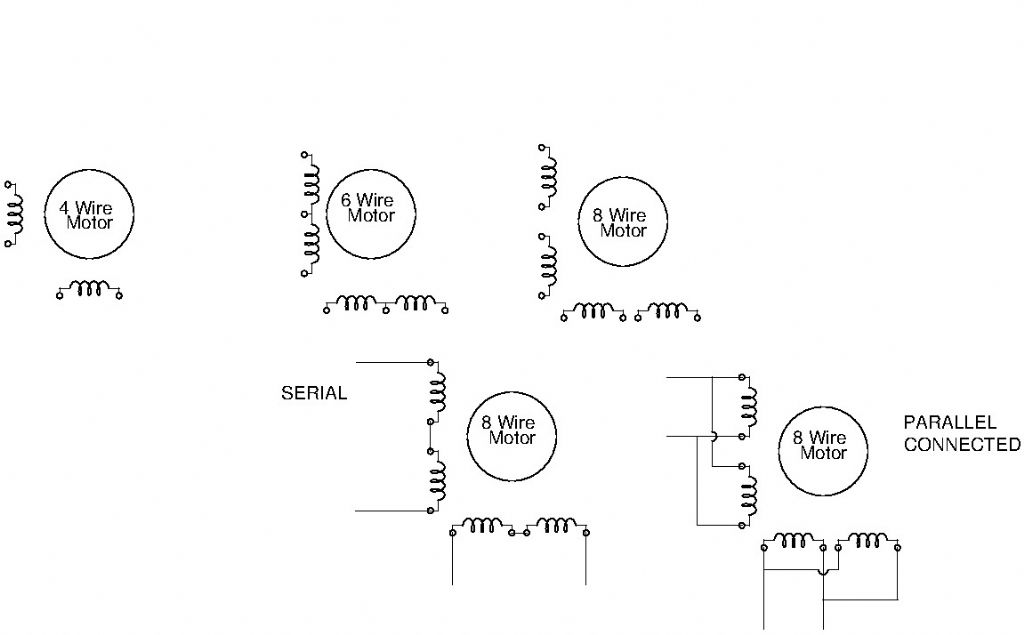

When I looked at the motor Nema 23 motor details from Zapp Automation it shows a motor with 8 wires, but on page 69 of issue 249 it shows a captive plug with 5 terminals and presumably a 4 wire motor. Will some one put me on the straight and narrow. …

Hi John,

These motors come in 4-wire, 6-wire and 8-wire versions. They will all work with 4-wires.

The diagram shows the possibilities, and their essential similarity. The 6-wire motor is the same as a 4 wire motor except the coils have a centre tap. You just ignore the centre tap.

Eight wire motors go a step beyond the 6-wire centre tap type by winding 4 separate coils on the motor. Bit more complicated. There are two ways to wire these for 4 wire operation as shown above, serial and parallel.

Which to use depends on the specification of the particular motor and your power supply, but usually wire them in serial as shown bottom left.

Most web sellers put specifications of their stepper motors on line so you know the wire colours and voltages.

Dave

Mark Simpson 1.