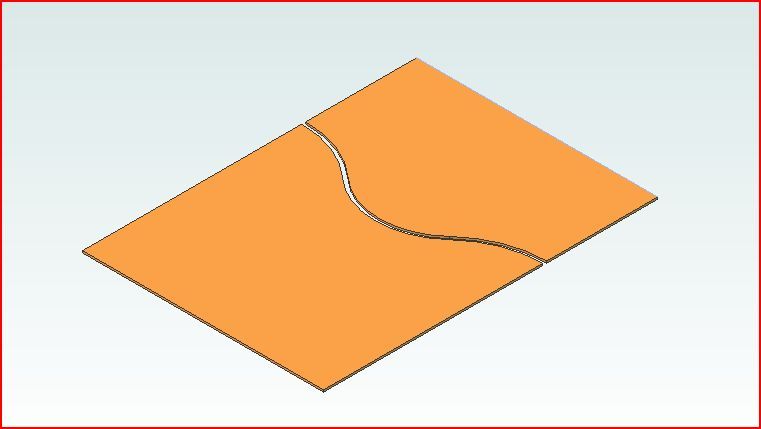

I admit I gave up on trying to work out whether I had 3 teeth in the material – I tend to pick the blade according to how coarse the work is. If I'm sizing a ring I'll use a coarser blade as they track better in thicker material, while for finer work I'll go for something a bit more refined. 4/0 is my go-to blade for cutting 0.7-1.0mm sheet, although if I'm piercing thicker steel (around 3mm) I might well use a 4. The blanking dies I've been cutting in 1/16 O1 I've used 2/0 although the shapes haven't really needed blades that fine.

They're a more delicate tool than a hacksaw, requiring a gentler touch. As for depth of throat – OK, I've got between 1 and 8" saws but you can twist the ends of the blade 90 degrees and cut across; it's a bit of a bodge, but it can be helpful.

If you want a gucci sawframe then I like my Knew Concept frames – they are a bit Marmite though; some people don't get on with them at all. That said, I use a couple of much, much cheaper frames as well – sub £10. Just don't skimp on the blades and use a bench pin to support the work.

Michael Gilligan.

Michael Gilligan.

]

] Something to do with the old saw (?!) about what everything looks like when you have a hammer.

Something to do with the old saw (?!) about what everything looks like when you have a hammer.