I have a Warco 220 lathe which is a rebadged Mashstroy 210T. The cross-slide dial is dual calibrated but I only use metric divisions. The dial shows amount taken off the diameter which I do not have any problem with at all. If anything, it is convenient because I usually measure the diameter of the workpiece, determine how much to take off, and then set up the cross-slide to reduce the diameter by that amount. The vast majority of what I do concerns work in the round, indeed I cannot recall any occasion where the linear movement (2mm pitch by the way) has been necessary. In any case, I can't see it being a problem halving the dial readings.

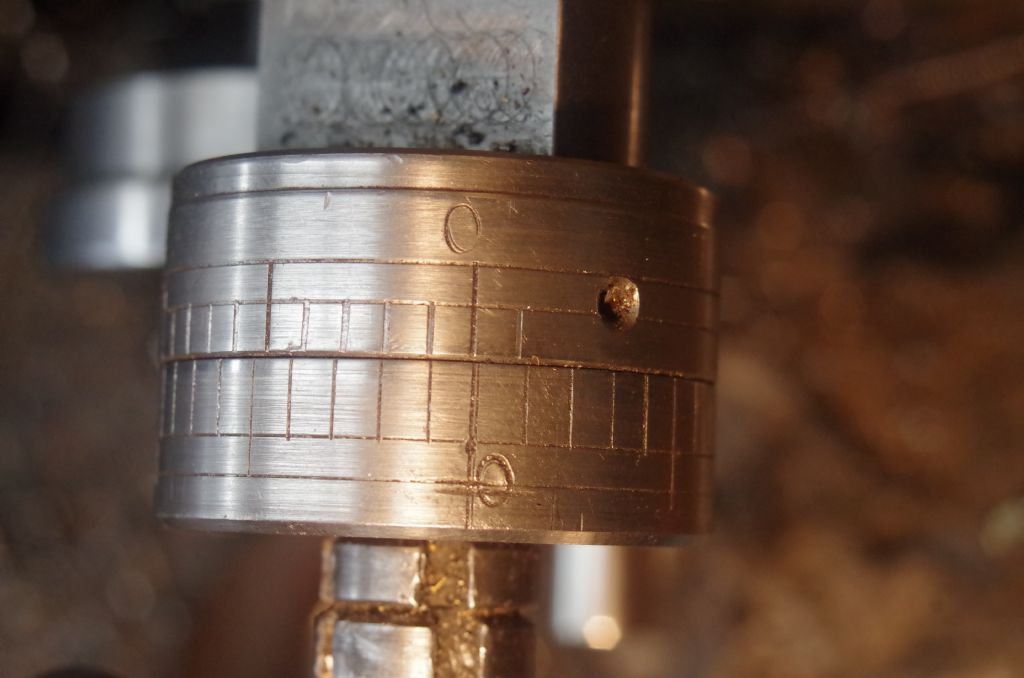

Where the dials do fall down is that the graduations are 0.05mm apart which means that for diameter reductions of less than 0.05mm, I have to estimate how far to turn the dial past the appropriate marking, however, I do find it relatively easy to estimate down to 0.01mm by using the guidelines suggested in a document produced by the National Physical Laboratory – Good Practice Guide No.40 in which they suggest that the thickness of the calibration lines on the dials should be equivalent to 20% of the distance between calibration lines. Therefore, for me to remove 0.01mm from, say, a diameter of 10.01mm, requires me to set the dial markings such that one side of the appropriate movable dial marking coincides with the opposite side of the fixed or fidudicial line.

Estimating to 0.025mm is easy – halfway between any two marks. Similarly, 0.0333mm or 0.0666mm is easy – simply set the movable dial such that the fixed marking is at 1/3 or 2/3 as appropriate.

The same article also discusses the effects of heat, or the lack of it, and certainly in my case, with temperatures in my shop which can vary between cold and warm (extreme variations of these and I abandon work) there would seem to be very little point in me attempting to work to 0.001mm.

The document mentioned above was recommended by someone, possibly Neil Wyatt, as being available for download, which is what I did, hence I cannot tell you how to obtain it. What I can say, is that it is a very interesting read covering, as it does, micrometers and caliper, including care & maintenenance along with how to use them.

Peter G. Shaw

Nigel McBurney 1.