Posted by John Haine on 14/05/2020 21:21:05:

My understanding was always that metric lathes had their cross slide calibrated in mm off the diameter, imperial in inches off the radius (i.e. actual tool infeed). All the metric lathes I have owned/used follow this convention.

Footling about in the history of machine tools, modern lathes combining a lead-screw, slide-rest, and change-gears are due to Henry Maudslay. Around 1800 he appears to have established the British practice of working in depth of cut rather than reduction in diameter. Not daft, but neither is it ideal because diameter working is more common.

The down-side of being an engineering pioneer is it tends to embed old ways of doing things firmly in the minds of workmen, making it very difficult to change later. Turners trained on depth-of-cut are upset and bothered by diameter dials and vice-versa.

Countries that joined the industrial revolution later were free to improve on British ideas. As most lathe operations reduce diameter, it's handy to graduate dials for that, because it reduces the amount of arithmetic needed slightly and reduces errors.

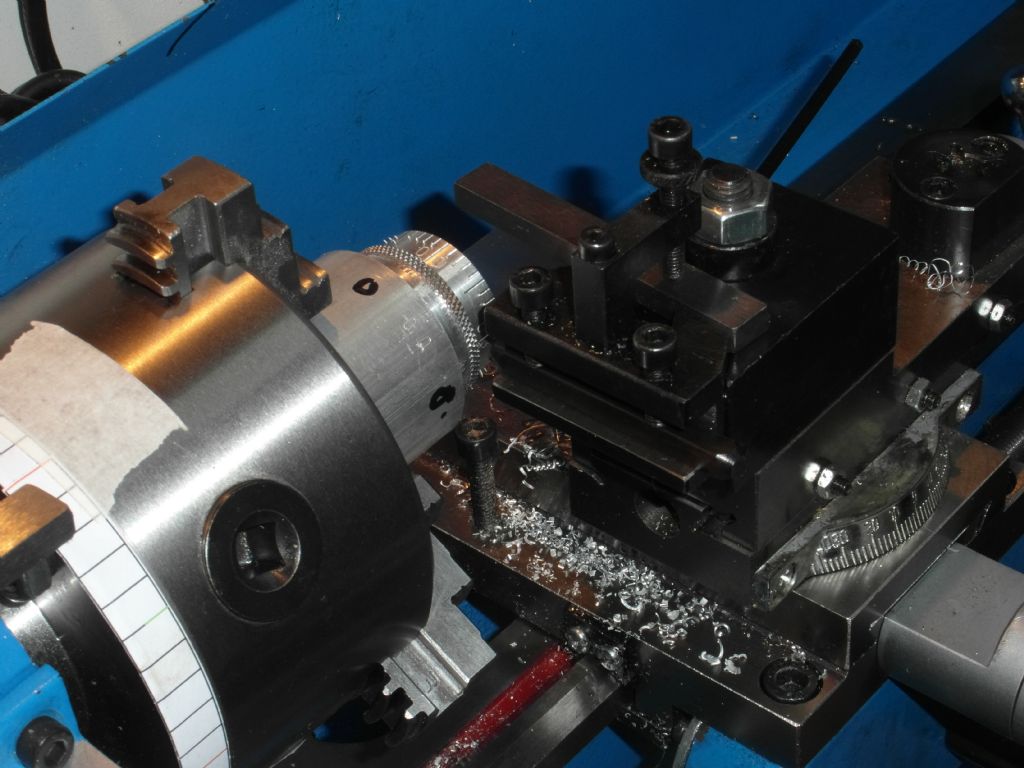

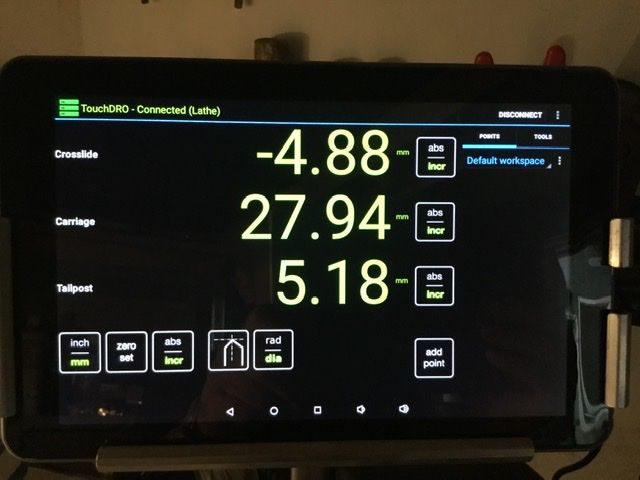

So British lathes, workshops and factories preferred depth-of-cut graduations for historic reasons, while everyone else prefers diameter. But it's far from consistent: later British lathes do diameters whilst some foreign lathes do radius. Much less of a hot issue these days because most manual turning is done by intelligent chaps who can do either, rather than lines of semi-skilled workers turning in factories and likely hating it! CNC can do either or both and fitting a DRO pretty much makes the dial graduations irrelevant.

Dave

Nigel McBurney 1.