Colchester Student Mk1 Won’t Start

Colchester Student Mk1 Won’t Start

- This topic has 796 replies, 39 voices, and was last updated 5 June 2021 at 16:31 by

Phil Whitley.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Transwave converter – plugged in motor, tripped RCD

- What a flipping cheek !

- Traditional fly press uses

- Unusual lathe chuck

- Help Wire 3 Phase 2 Speed Motor

- What is this Colchester accessory used for?

- Mary beam engine

- Boiler Design – issue 4765

- Recommended storage for heavy lathe tooling

- Suspicious Post? (Letters)

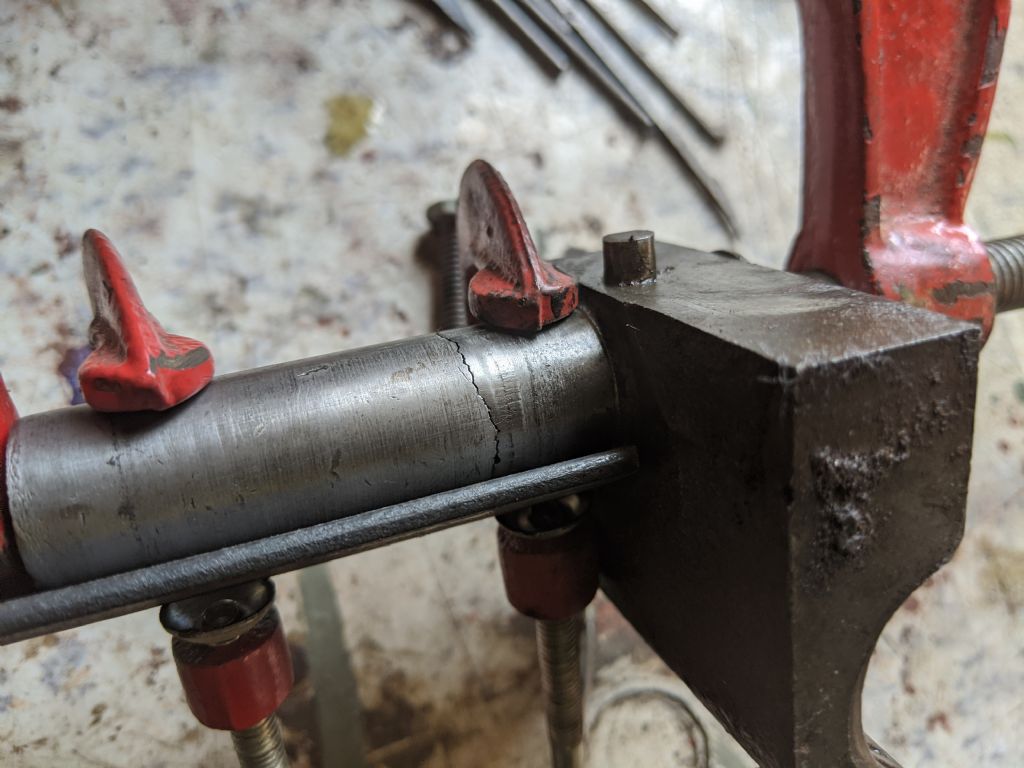

) but the machine definitely works and will work in the near future. Or at least I hope…

) but the machine definitely works and will work in the near future. Or at least I hope…