I'm very impressed at your speed Herman, you seem to be getting things done very quickly. It feels like I've been working on my lathe forever(not in a bad way)

Anyway, today I cleaned the light bulb contacts with a bit of 600 grit. They were definitely not clean, but now they are

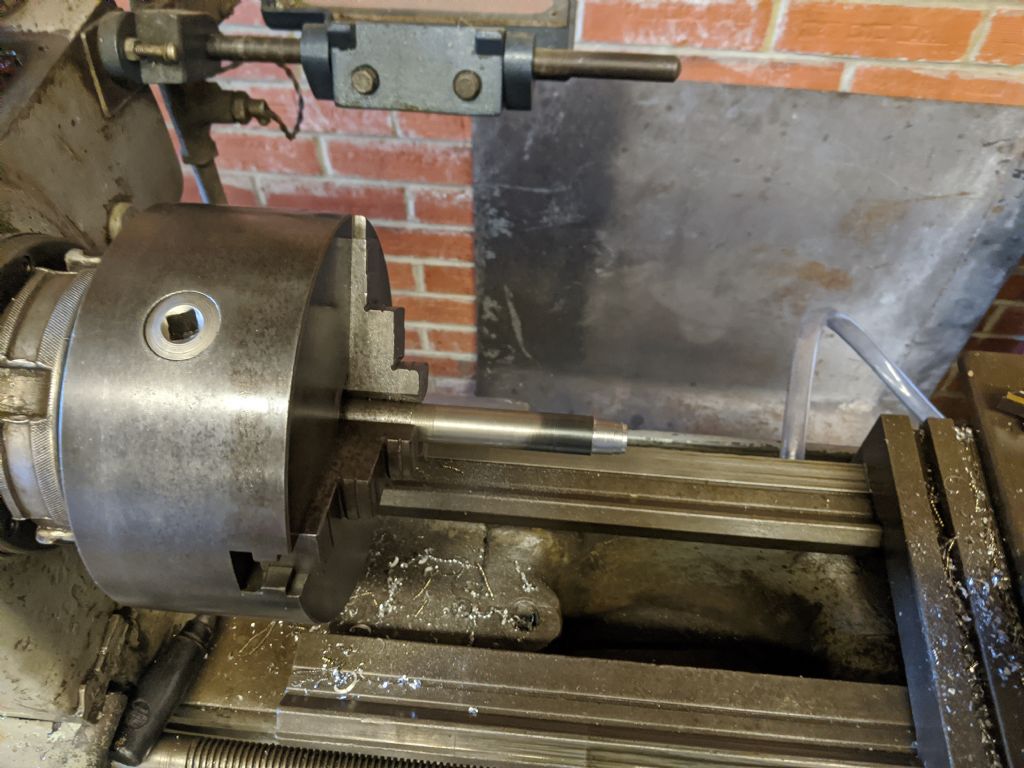

Then I began work on a dedicated ring spanner for the tailstock. I wanted to make this a large spanner, bigger than the original which I have seen pictures of. So, I'm using a piece of 10x50x220mm steel I started by laying out the nut, then chain drilling and filing till I had the fit I was looking for

I liked the size and shape of one of the spanners I had, so I made it a similar shape

So I shaped it with an angle grinder, grinding disk, then flap wheel, then I moved to the belt grinder which I used to get to final shape then round all the edges

Then I used a surface conditioning wheel to get a consistent surface finish all over, which I then cold blued

Initials and year stamped in to show when this has all been done.

I think its very comfortable. Not hard to find, and its not symetrical, so you get more clearance instead of it hitting the tailstock casting

Finally, I added a washer to spread the load a bit better since the nut was getting marks in it.

This also raised the nut so the spanner fit in a better position for locking. Not too sure how to explain that properly, but it works very well now!

Anyway, back to Herman

Was the Headstock very heavy once emptied Herman? Were you able to lift it by yourself?

Reading your most recent write up post, I also really struggled to remove the gearbox selector screws that hold the comb thing. Lots of penetrating oil and they still took a lot of force, with a very loud snap they came out. Clearly from your picture in here you managed to get them out

Edited By Richard Kirkman 1 on 21/05/2020 19:09:49

Phil Whitley.