… and before some Smart Alec complains, yes, the alliteration is deliberate!

.

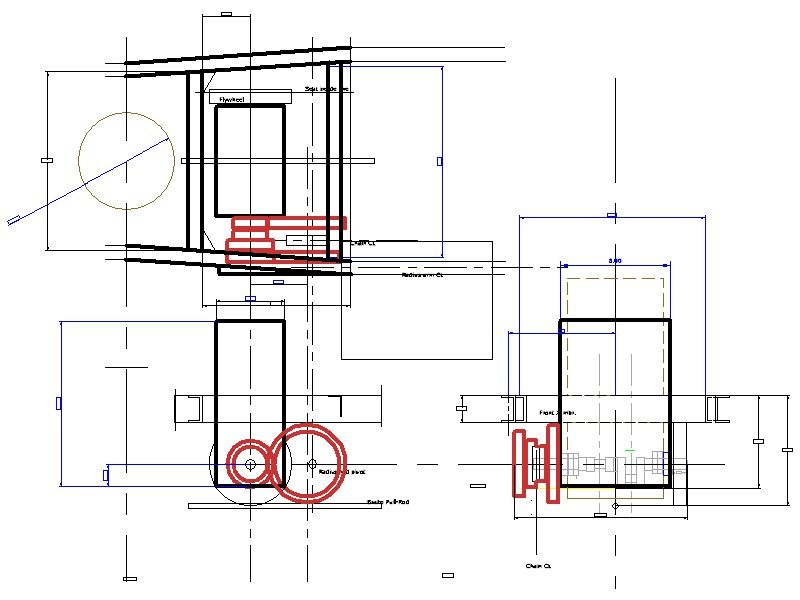

Designing my steam-wagon's two-speed, two-shaft gearing, I found that a long-saved pinion and gear set could give a reasonable low gear, allied to the sprocket reduction of the final drive, and will fit the chassis fairly well.

The wheels carry no identity marks, but careful measuring revealed metric dimensions, and 2 MOD size. So we need make the high gear also 2 MOD.

The existing wheels' tooth counts are 32 and 72, so the high-gear tooth-count sum needs also be 104.

So far so good.

'

Before buying the other wheels, equally obviously I need again verify the tooth counts, by physically counting using a felt-tip pen to "tick" them off and highlight the tens.

Also, I thought, test it by running the pinion, with one gullet marked, round its mate with one tooth marked.

'

That's where the fun starts.

The pinion's start gullet should meet main wheel tooth 64, remainder 8 left to go. Only it doesn't!

No end of repeats brought no solution; but revealed they reunite on the pinion's Circuit Number 4; again at 8, again at 12.

'

So I synthesised the problem by a simple spreadsheet consisting of a column of 1-32 repeats, alongside a column of 1-72 repeats.

That showed the pinion's start gullet should collect the main wheel start tooth on every 9th complete orbit of pinion round wheel. There, the accumulated main wheel tooth is the 288th by spreadsheet row number, an integer multiple of both 32 and 72. (By 9 and 4 respectively)

Only that does not happen when physically running the pinion round the wheel, on the table: it happens every 4 orbits.

I wondered if in fact the two wheels, of uncertain origin but apparently unused, are perhaps of MOD and DP formats, but they would run out of pitch only a short way round.

Or is the wheel of 71 teeth, my first count? That would not give this strange every-4 orbits behaviour, and the spreadsheet's 71s columns reveal the hunting action.

Count physically yet again: 72 teeth.

Then put the wheels away and go for a pint!

.

This matters because I am trying to verify what I need buy for the accompanying two gears for equal centres, yet these anomalies suggest my arithmetic is totally wrong.

So where am I going wrong, please?

.

[Yes I know I'd gain extra Brownie Points by cutting the wretched things myself but I want to finish the damn' vehicle before Nature finishes me, and I want the gears to work. The whole project has taken a ridiculously excessive time as it is! Besides, many professional engineering companies use stock gears, and probably did 100+ years ago, so if it's good enough for them….)

.

Oh, and there are such things as "cogs". Millwright-speak for the inserted teeth in mill gears, not the complete wheels. In flour mills they are of hardwood, running against cast, all-iron, pinions; a combination that crucially cannot spark, but as a by-product is also very smooth and quiet.

Nigel Graham 2.