Concerning connectors this picture shows the two common general purpose quick release airline connectors. I had both types floating around and made adapters as a temporary measure pending exploiting very attractive LiDL prices for Euro connectors to convert everything to Euro. As ever temporary became permanent and mumble-mumble years on I still have a mix.

Bottom is a Euro female to PCL male adapter. Note the bulge in the main stem characteristic of the standard PCL

Middle is a modern style PCL female to Euro male adapter. Note the parallel stem characteristic of the Euro.

Top is an old style PCL female.

Pull back on the sleeve to release the female coupling on both types.

Generally standard PCL females have knurled rings to assist grip whilst Euro have plain rings but you can’t assume this is true for everything.

Many PCL females are positive latching requiring the sleeve to be pushed forward to unlatch before pulling back to release the coupling. Generally if there is a gap between the sleeve and the connector entry, as per the middle one in the picture, it will be positive latching. Unless the system is completely de-pressurised it’s usually necessary to push the male connector towards the female one to get the positive lock latch to release. The whole point being that you need two hands to undo the connection which is obviously safer. Ageing positive latch PCL females can be a right pain to undo.

Euro connector has a slightly larger bore and tends to be bit easier to release. It is said they are less durable than PCL but how much of that is due to the proliferation of inexpensive import ones made to slack tolerances I know not. I seriously doubt that any member of our fraternity will use one enough to wear it out.

A major trap for the unwary is that PCL branded PCL-XL range connectors are Euro type not proper, standard PCL.

The female end is self sealing and should be fitted on the pressure side. The male goes on the tool or whatever. Should be obvious but I have encountered a hose connected the wrong way. Fortunately I had a good grip, even with only about 50 psi in it the hoes was, ahem, energetic in attempting to escape.

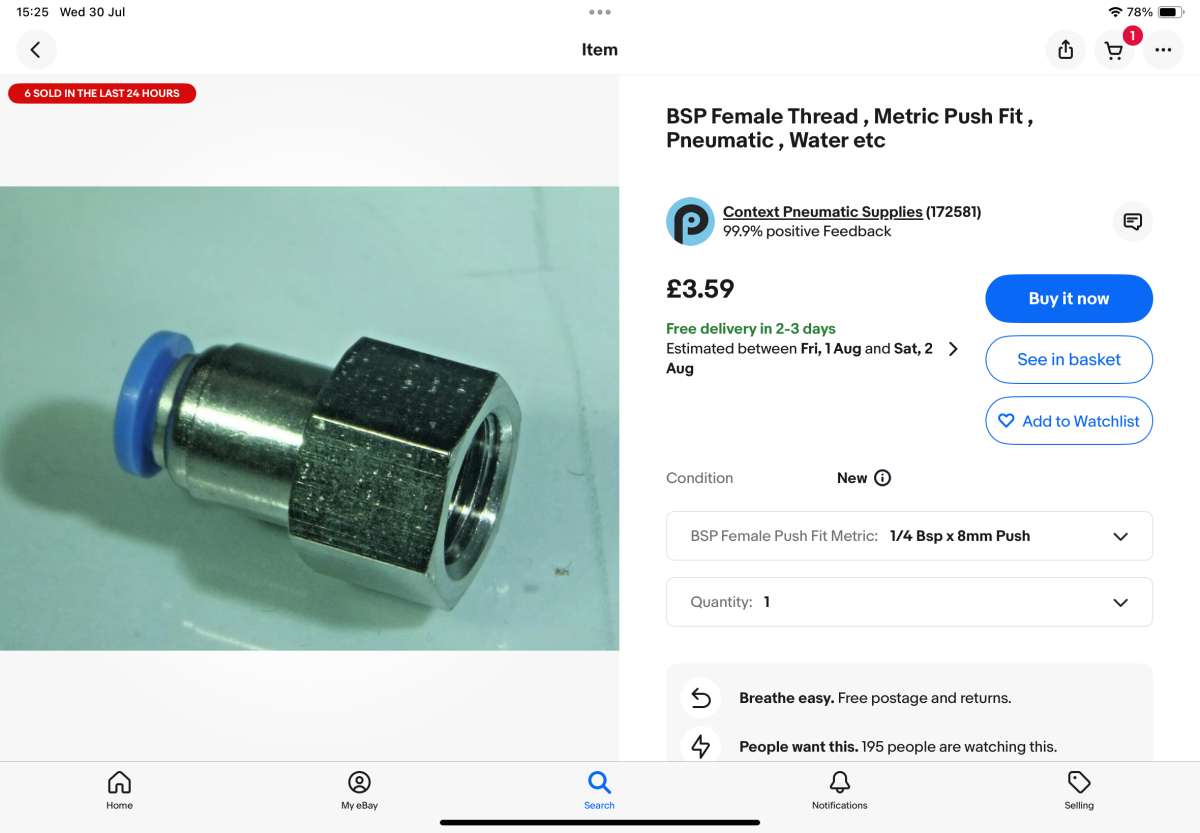

The simple nylon tube push fit types make effective quick release connections if you don’t mind de-pressuring things before you attempt to disconnect. Alternatively (better) put a tap in the line to cut off pressure.

I would consider a tap on the entry side of the very neat Euro inlet to multiple push fit outlet manifold pictured in previous posts essential.

Theoretically the push fit pipe end should be cut off and re-chamfered before re-connecting but in practice you can disconnect and re-connect several times before the nylon hose deforms where the O-ring seal(s) run leading to leaks. Industrial rated (aka expensive) ones have two O rings and are more reliable at high pressures. Watch the temperature ratings. The cheap and cheerful plastic breed don’t like getting hot. Typically maximum of 60°C. Metal bodied versions rated up to around 150°C can be found, at a price.

Nylon air pipe is generally stiffer, stronger and has higher temperature range than the (cheaper) polyurethane type.

Clive

JasonB.

JasonB.