Chain Hoist Tripod in MEW 264

Chain Hoist Tripod in MEW 264

Home › Forums › Workshop Tools and Tooling › Chain Hoist Tripod in MEW 264

- This topic has 54 replies, 18 voices, and was last updated 11 August 2018 at 21:44 by

Meunier.

-

AuthorPosts

-

5 August 2018 at 14:29 #365706

Anonymous

I'm darn glad I don't live in Australia, and they've got the cheek to call us whinging Poms.

I take it the OP isn't an engineer, or he'd be capable of doing the basic calculations. In these sort of structures buckling failure is most likely. As Martin says the Euler formula gives the basics.

Andrew

5 August 2018 at 16:10 #365718Clive Foster

Participant@clivefoster55965The obvious theoretical weakness in this design of tripod is the reliance of simple welds between tubes and a flat plate to carry all the compound stresses in use. Given decent welding its obviously amply strong enough but in a design for publication its probably inappropriate to rely on professional, or at least good, welding.

All objections would be answered if the simple flat plate were replaced by a flanged structure comprising three flat sides welded tangentially to the outside of the short tubes, forming a basic open top triangle, and the flat plate subsequently welded on top. It would also be prudent to make the hanger as a U bolt rather than plain rod so nuts could be screwed on, acting as a positive retainer, before welding in place. Assuming anything reasonable underfoot it ain't going anywhere.

Apologies for reiteration but at loads of a ton and below any remotely rational structure will bend or deflect in a most alarming manner long before actual failure. Consider the humble scaffold hoist, whether ex Lidl or more professional, usually hung from the freely upstanding part of a scaffold pole a few feet above the uppermost walkway. The pole bends but it doesn't break. But the builder of my extension wasn't amused when told in no uncertain terms to properly brace the scaffold before lifting a 15 ft RSJ. My hoist, my extension, my beam, my scaffolding bill, my rules.

Rational of course means avoiding direct tensile or bending loads on simple welded joints and not putting compression loads through slender sections. Above a ton or so you'd better start engineering or sections start getting silly large.

For anyone with an interest in this sort structural strength thing I would commend the book "Why Buildings Fall Down" by Matthys Level and Mario Salvadori along, although to a lesser extent, its companion volume "Why Buildings Stand Up" by Mario Salvadori alone. The first book in particular not only gives eye opening examples of the sort of unthinking lunacy that can be perpetuated by so called professional engineers but also, if you care to run the numbers, some surprising illustrations of just how strong things can be. Although structures seriously aren't my field I'm not exactly a lay person in this area but no way would I dream of working to the safe loadings specified. The description of lift-slab building methods and the weld-on wedge technique used to temporarily keep things in place before installing the walls got my eyebrows raised so far that they almost disappeared down my back collar! Definitely a McEnroe "You cannot be serious" moment for me but, apparently, it works. Usually!

Clive.

5 August 2018 at 16:16 #365720not done it yet

Participant@notdoneityetIf I were to make something myself, I would test it to a considerable margin beyond what I would normally load it. That goes for anything I buy in, second hand, if I consider it necessary.

My air receiver was tested, hydraulically, to twice its operating pressure before I trusted it. Time to test it again, I suppose.

All the air receivers, at work, used to be checked and assessed for insurance on a regular basis. All the lifting gear was also regularly inspected by a responsible person. All the cranes were checked for insurance reasons, too. All electrical items were checked regularly for safety – particularly extension leads and work lights!

If a design gives a lifting capacity, it should be designed for rather more. These items are not shop-bought, which are a diffeent matter entirely. I’ve not seen the design, to which this thread relates, so am unable to comment on that particular item, but there may well be better ways to carry out the construction and these should be highlighted as appropriate.

5 August 2018 at 16:47 #365727SillyOldDuffer

Moderator@sillyolddufferPosted by Andrew Johnston on 05/08/2018 14:29:28:…

In these sort of structures buckling failure is most likely.

…

Andrew

No criticism intended of the article but it's often interesting to list the possible causes of failure in a structure. Best done with a numerate approach, but Euler and Bow's Notation are beyond me. Too hot today to even try.

My list for Stan's tripod would include failure of the:

- U-bolt

- U-bolt fixing, especially if threaded rather than welded

- 1/4" mild steel triangular plate by bending or pull-through of the u-bolt.

- welds, especially if done badly, or damaged by levering

- scaffold poles by buckling

- footings, if one sinks more than the others creating an eccentric load sufficient to cause buckling, or disturbs the centre of gravity sufficient for the tripod to fall over.

- footings, if friction is unable to resist the force tending to push the legs apart at ground level. (This force will be largish, and splaying is likely on a slippery hard surface.)

- adaptor plate by torsion, if subjected to an eccentric load.

Assuming the feet are prevented from splaying by suitable ground conditions or rods, and given that the columns are strong scaffold poles, I feel the adaptor plate is the most vulnerable part.

Stan's tractor weighs about 200kg and my gut feel is the plate is plenty strong enough for that, and it could easily be uprated. It would be enormous fun to test one of these to destruction, assuming that is you could get the necessary weight inside the tripod!

As always use anything you make yourself at your own risk. Fortunately forum members are intelligent customers and I don't think they'd get into danger with one of these because the risks are obvious. More dangerous I think, is people dabbling with the unknown, like powerful chemicals, radioactivity, electricity, or bio-hazards, all of which present non-obvious hazards. Chap on Radio 4 warning this week about the need to react quickly if you get sepsis. Most people don't recognise the symptoms. Poor man is a multiple amputee after being 'nipped by my dog…'

Dave

5 August 2018 at 17:16 #365733 JasonBModerator@jasonb

JasonBModerator@jasonbI think the biggest risk of failure is as per the first post using it of a smooth concrete surface and the legs spreading. Even if the welds held it would easily bend the 1/4 x 3/4 to 1" corner of the triangle. I know I could bend it easy enough with a 10ft scaffold pole as a lever.

That's if the scabby bit of nylon rope did not fail first.

Edited By JasonB on 05/08/2018 17:17:30

6 August 2018 at 00:18 #365781Ian Austin

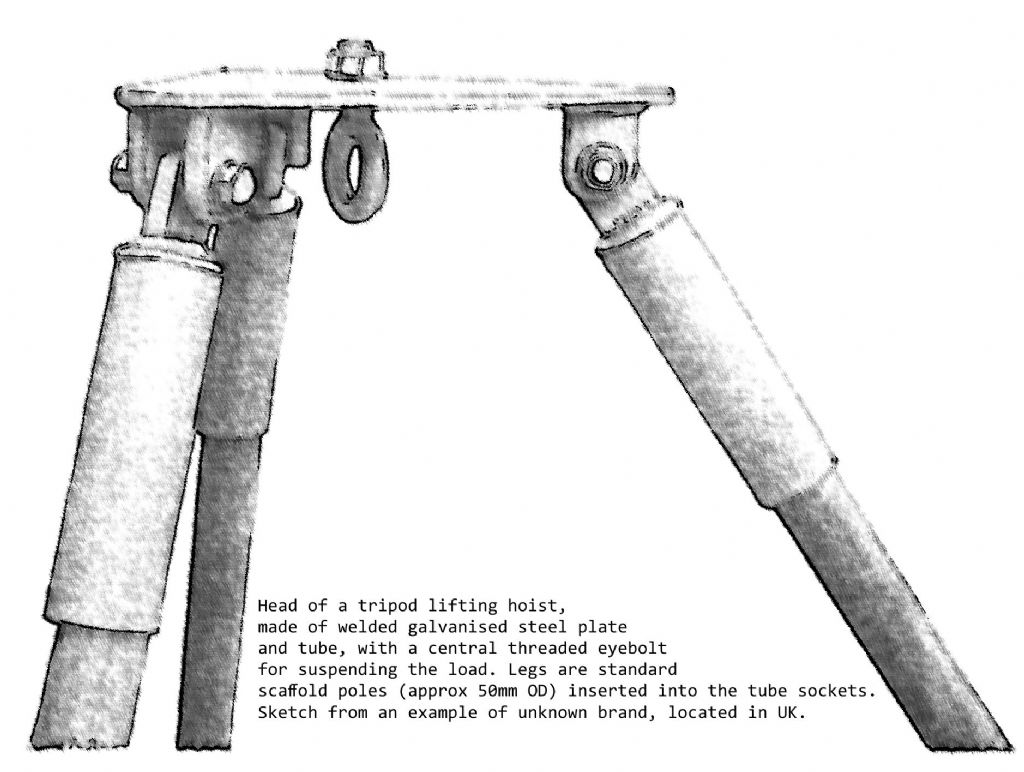

Participant@ianaustinI had a google around for images of 'scaffold pole tripod', 'tripod hoist', 'tripod lifting crane' etc.

Here are just a few of what to me are the most interesting results, showing the tripod head in commercial products of about the same type we have been discussing:

Vestil:

https://www.vestil.com/products/mhequip/tripod_hoist_stands.htmCisco-Eagle:

http://www.cisco-eagle.com/catalog/product/166339/aluminum-tripod-gantry-crane-1-ton-cap-8-7-max-lifting-htLifting Safety UK:

https://www.liftingsafety.co.uk/product/aluminium-tripod-crane-1000kg-3090.htmlUnknown brand:

https://www.preloved.co.uk/adverts/show/114580540/lifting-tripod-head.html To me the first two websites both from USA) show the most interesting design of tripod head. Two different brands (Cisco-Eagle and Vestil), but similar thinking. The Lifting Safety UK design looks for difficult to fabricate but this is a UK forum so I've linked it.

The last image is from a current UK second-hand advert, (the link will die fairly soon so take a screenshot while you can), but is possibly most like what various participants in this thread here might be thinking of, and is also very interesting.

All seem to use a threaded eyebolt for the suspension point. Note also the style of feet on the US designs, and the use of an anti-spreading safety chain or rope, either at mid-height or at the feet.

I think its great that MEW will take a second look at design of this handy type of equipment, and I'll be interested to see what Neil comes up with.

Although I suppose I've been contentious and offputting for a first-time poster, I won't be convinced that the bar for safety on lifting equipment is anything but high, and any diy construction or design discussion needs to reflect that.

Edited By Ian Austin on 06/08/2018 00:25:22

Edited By Ian Austin on 06/08/2018 00:28:21

6 August 2018 at 08:35 #365800Ian Austin

Participant@ianaustin6 August 2018 at 09:03 #365802Clive Foster

Participant@clivefoster55965Interesting links.

The scaffold-pole tripod head system is structurally incomplete on its own. Needs a triangle of horizontal poles to stop the legs splaying out and causing the whole thing to collapse.

Other links are interesting. Demonstrate that normal commercial practice is to use a cap style head of finite depth rather than a simple plate. Which clearly adds considerable extra resistance to leg splaying.

The outrageously expensive aluminium version from Lifting Safety clearly shows that simple rubber pads coupled with a cap type top are considered entirely adequate to prevent splaying. Even on a smooth floor. Putting some numbers in the splay forces for a nominal one ton / 1000 kg load are around 250 lb / 120 kg per leg in round numbers.

With pin joints on top as per the scaffold pole system all the splay forces would have to be resisted at the bottom of the leg unless horizontal stays are added.

With a cap most of the splay force is taken at the top so only residual forces need to be absorbed at the bottom of the leg. The simple welded on flat plate used in the original article is clearly going to be weaker but obviously is adequate in practice on normally non-smooth surfaces.

Given that the scaffolding system used in the original design has welded on loops on each section specifically provided for bracing cables adding extra bracing to resist splay if desired would be easy. A couple of loops of common agricultural plastic binder twine would be ample.

Perhaps the OP should have suggested this in the first place. But then this thread wouldn't have been as much fun.

Clive.

PS Live links showed up just fine on my computer last night but this morning they have reverted to text strings. Weird!

Edited By Clive Foster on 06/08/2018 09:04:44

6 August 2018 at 10:47 #365821duncan webster 1

Participant@duncanwebster1Posted by Ian Austin on 06/08/2018 08:35:23:Here is a sketch of the scaffold-pole tripod head that appeared in a second-hand advert, mentioned above.

That's not a structure, it's a mechanism. Even with the bottoms of the legs tied together it can all move.

Edited By duncan webster on 06/08/2018 11:07:50

6 August 2018 at 10:47 #365822SillyOldDuffer

Moderator@sillyolddufferPosted by Clive Foster on 06/08/2018 09:03:54:Interesting links.

…

The outrageously expensive aluminium version from Lifting Safety clearly shows that simple rubber pads coupled with a cap type top are considered entirely adequate to prevent splaying. Even on a smooth floor. Putting some numbers in the splay forces for a nominal one ton / 1000 kg load are around 250 lb / 120 kg per leg in round numbers.

…

We have probably all seen splay in action on a ladder. I expect most of us have seen one slip.

On the smooth concrete paving making up my back patio, my ladder normally shows no signs of slipping. However, it did slip one wet day, fortunately not when I was at the top! The slabs were slimy due to some sort of growth. Helping my dad as a skinny teenager, I once slid gently down a wall from gutter height. Luckily for me, the feet were on grass, which acted as a brake with comic results. Now I'm a chubster, I like to tie ladders at the top, pay close attention to the ground, always put concrete blocks down to discourage sliding, and have someone stand on the bottom rung.

I think Clive's splay force of about 120kg (260lb) for a ton lift is about right. It's a force well worth controlling and it can be done with little more than stout string. Think of what would happen if you were safely up a ladder and a boy pulled the bottom rung away from the wall. Quite a small boy could kill you.

Ladders are surely far more dangerous than Stan's tripod.

Dave

6 August 2018 at 11:07 #365828Ian Austin

Participant@ianaustinOP … should have suggested in the first place … who? moi? Oh, I'm just learning as I go — knew nothing about any of it before yesterday.

But nice interpretative commentary on the different designs, Clive.

I guess one other thing about the original design published in MEW, with its fixed-angle pole sockets, is that it will really only work on level ground, whereas, to some extent, the swinging leg types might be adjusted to uneven ground — some designs also have telescoping legs, with a series of holes along them for pins — nice for sloping ground. Telescoping legs would then have the anti-splay chain halfway up, at the base of the upper tube.

Also, it becomes clearer why the original MEW-published design is less suited to free-for-all home fabrication, because the length of weld that joins the sockets to the plate is tiny in comparison to these other types that have a longer joining surface – making the quality of the weld far more critical in the MEW design, and more redundant in the others. As well, there is the issue of leverage pointed out in an earlier post — i.e. it is fairly easy to apply a damaging lever force to the sockets on the MEW-published design – a disadvantage that is absent from the 'cap' type designs.

Edited By Ian Austin on 06/08/2018 11:09:26

Edited By Ian Austin on 06/08/2018 11:14:16

6 August 2018 at 11:09 #365831Gordon W

Participant@gordonwWe used to make lifting tripods out of 3 sticks and some light rope. Never lifted much over a body weight but had no problems. This was before I could calculate the forces involved. Learnt in the Boy Scouts.

6 August 2018 at 11:28 #365833Ian Austin

Participant@ianaustinPosted by duncan webster on 06/08/2018 10:47:16:That's not a structure, it's a mechanism. Even with the bottoms of the legs tied together it can all move.

Wouldn't that only be if the lugs holding the tube sockets bent across the plane of action? As in, two of the lug-pairs would have to bend as the third leg moved over the centre? Or am I not visualising that right?

Re scouts – yes, we made one like that at scouts too — which has just reminded me of a description of that type (rope and timber poles) in the Admiralty Manual of Seamanship 1952 edition vol2, pp 218-19, as an "extempore gyn" — I'd forgotten about that, just looking at that now.

Edited By Ian Austin on 06/08/2018 11:34:41

6 August 2018 at 12:00 #365845SillyOldDuffer

Moderator@sillyolddufferPosted by Gordon W on 06/08/2018 11:09:30:We used to make lifting tripods out of 3 sticks and some light rope. Never lifted much over a body weight but had no problems. This was before I could calculate the forces involved. Learnt in the Boy Scouts.

As Clive said earlier: 'Up to a short ton or so lifting structures tend to fall into the "if its stiff enough its strong enough" category. So long as it doesn't wobble about all over the place and looks about right on a "monkey see, monkey do" basis relative to normal practice such things are almost certain to be safe in occasional by a reasonably intelligent person.'

Stan's tripod is interesting because the chain-lift is rated to 1000kg, implying (perhaps) that the tripod is completely safe to that weight. Actually, though perhaps the tripod is plenty strong enough, we don't know that and Stan didn't claim it.

I'm very tempted to publish a truly outrageous tripod design based on the boy scout approach with extra ignorance, that claims to lift several tons while obliging the operator to stand underneath the load. I don't think anyone would be fooled by the spoof, but publishing it wouldn't exactly be responsible either.

I suggest 5 categories of lift for which a tripod might be used:

- Relatively tiny load (150kg) lifted once or twice with a tiny chance of serious injury. (Boy scouts)

- Large load lifted once dangerously in an emergency by men paid to die for their country. (Soldiers)

- Small load carefully lifted occasionally by an intelligent operator using components likely to be overrated. Clive suggests <1000kg is a small load. I'm more comfortable with 500kg, but wouldn't argue with him. This scenario suits mechanically minded practical chaps working on engines.

- Equipment designed to lift loads repeatedly and be operated by untrained operators. Design is number-crunched, with materials selected and manufactured to minimise risk. (Operated in commercial or domestic circumstances where an injury could result in a prosecution. Limitations clearly explained.)

- Difficult lifts requiring professional design, assembly and experienced operators. (As 4, plus high risk insurance complications.)

Stan's design fits category 3 and it's interesting because the design can be improved on somewhat and we can speculate about its limitations.

Dave

Edited By SillyOldDuffer on 06/08/2018 12:03:53

6 August 2018 at 14:13 #365876duncan webster 1

Participant@duncanwebster1Posted by Ian Austin on 06/08/2018 11:28:25:Posted by duncan webster on 06/08/2018 10:47:16:That's not a structure, it's a mechanism. Even with the bottoms of the legs tied together it can all move.

Wouldn't that only be if the lugs holding the tube sockets bent across the plane of action? As in, two of the lug-pairs would have to bend as the third leg moved over the centre? Or am I not visualising that right?

Re scouts – yes, we made one like that at scouts too — which has just reminded me of a description of that type (rope and timber poles) in the Admiralty Manual of Seamanship 1952 edition vol2, pp 218-19, as an "extempore gyn" — I'd forgotten about that, just looking at that now.

Edited By Ian Austin on 06/08/2018 11:34:41

the gap between the vertical lugs looks a lot wider than the blade on the end of the upright, and there will be clearance on the pin, so it will wobble until some clearance somewhere is taken up.

I too used to be a scoutleader, and have supervised the making of dozens of tripods out of rope and pioneering poles. Always either tied the bottoms of the legs together or dug a hole and buried them

7 August 2018 at 12:28 #366082Ian Austin

Participant@ianaustinWell, I eventually did make a calculation of the MEW-published tripod according to Euler's critical load formula for buckling columns. I'll copy-paste in the whole calculation below, along with a short discussion.

The executive summary is this: I used a spreadsheet, and ensured that the spreadsheet would replicate another example I found on the web — i.e. the spreadsheet does not contain any silly mistakes. I used the dimensions mentioned in the MEW article. I de-rated the Euler's calculation result by a safety factor of 2. The resulting maximum allowable load — by Euler's theory, not by field test — was 4200kg. In contrast, a similarly-sized commercial steel tripod (by Spanco) is rated at 1800kg for the heavy-duty version – with legs that look a lot chunkier than the 48mm scaffold poles here. So I would suggest that the simple Euler's calculation is not the full story.

For those that might like to see the nuts and bolts, here's my working-out and fuller discussion:

* * * * * * *

Tripod rated load – theoretical calculation by Euler’s critical load formula

As the legs on a tripod are slender columns, assume critical stress is lower than yield stress, and assume the failure mode will be buckling, where the column is subjected to a load greater than the tensile strength along the column’s long axis. Load is assumed to be purely axial without any eccentric load, so no bending stresses are calculated. This also implies that the load must not be swung in case it hits one of the legs. It is assumed that the legs are restrained from movement at their base by a lashing rope and at their head by pinned connections to a cap. The load is a suspended between the legs by an eyebolt centrally placed in the cap.

The calculation below relies on finding the critical load leading to failure, using Euler’s formula for critical load. This formula provides a value for the ultimate load, but to be sure that the structure will not fail, an ultimate factor of safety has to be applied, so that the structure will be sure to support the rated load without failing even if there are local imperfections in the materials.

Material: Standard steel scaffold poles

Modulus of Elasticity, E (approx.) = 200 GPa

Outside dia, Do = 48.3 mm

Inside dia, Di = 40.3 mm

Length of legs, L = 3.05 m

Angle of legs to ground = 70 degrees

Ultimate factor of safety (failure load/allowable load), FS = 2

Axial load capacity of one leg:

Area moment of inertia, I = (Do^4 – Di^4)*pi/64

where Do and Di are expressed in metres

I = (0.0483^4-0.0403^4)*pi/64 = 0.000000138 = 1.38*10^-7

Euler’s critical load:

Pcr = pi^2 * E * I / (K * L)^2

where

Pcr = Euler's critical load (longitudinal compression load on column),

E = modulus of elasticity of column material (200 GPa, expressed as 200*10^9 Pa),

I = minimum area moment of inertia of the cross section of the column,

L = unsupported length of column,

K = column effective length factor (take K as 1.0, i.e. both ends pinned)

Pcr = pi^2 * 200*10^9 * 1.37*10-7 / (1 * 3.05)^2 = 29214 N

Calculate the rated axial load capacity, Pax, of one leg:

(Pax is the force directed along the inclined leg)

Pax = Pcr / FS

Pax = axial load capacity of one leg = 29214 / 2 = 14607 N

Calculate Pz, the vertical component of Pax:

Pz = Pax * sin (70) = 13726 N

Calculate the total load for the three legs:

Total load Pztot = 3 * Pz = 41178 N

To obtain maximum permissible load in kilogram:

convert value for force in Newton to kilogram-force, where 1 kgf = 9.807 N

Pztot / 9.807 = 4200 kg

The result: according to the Euler buckling analysis, maximum permissible load on the tripod is 4200kg

This would need to be field tested by suspending a load 125% of rated capacity, i.e. 5250 kg to prove that 4200 kg is indeed the permissible maximum load rating.

The maximum load value changes as the legs are splayed more or less. If legs are splayed further out to a 60 degree angle, the maximum load decreases from 4200 kg to 3870 kg; whereas if the legs are moved in to an 80 degree angle the maximum load increases to 4400 kg.

In reality, commercial tripods in this size have far more conservative maximum load ratings. Spanco, an American company, sells steel tripods with legs that can adjust from 3.09m in length to 4.93m. They make the tripods in two grades, one rated to 1 ton (900kg) maximum load, and the other to 2 ton (1800kg). Incidentally, the Spanco tripod product manual states that the legs should not be splayed out to more than what works out to be about 70 degrees angle.

The comparison of the Euler's analysis to the commercial practice casts doubt on the usefulness of Euler's analysis, at least on its own, as a way to assess a load rating for a hoisting tripod.

* * * * * * *

7 August 2018 at 12:53 #366092richardandtracy

Participant@richardandtracyWhere I work the commercial practice is to use a factor of 6 rather than 2 on lifting equipment, so using the calculations by Ian above would suggest a rated load of 4200/3 = 1400 kg, which is more in line with what my 'gut feel' of 1 Tonne would suggest. I believe in the US the figure is more normally 4 (a family story goes that my grandfather apparently accidentally sank a Liberty Ship in WW2 with a tank because of this difference in safety factors between the UK & US).

For webbing slings, CE marked stuff has a factor of 7 minimum, and I have come across 10 being required for some bits of kit being used in the US, though I've never been clear whether this is a regulatory or customer requirement.

Regards,

Richard.

7 August 2018 at 13:26 #366101SillyOldDuffer

Moderator@sillyolddufferPosted by richardandtracy on 07/08/2018 12:53:42:Where I work the commercial practice is to use a factor of 6 rather than 2 on lifting equipment

…

That's in line with my understanding. The safety factor isn't just about breaking strain though, it also covers accumulative damage due to fatigue each time the equipment is used.

Most commercial airframes are scrapped when they exceed their designed number of pressurise/depressurise cycles, not because they are ever overloaded.

For the same lift, a frequently used tripod should have a higher safety factor than an infrequently used tripod. My local DIY store draws a sharp distinction between aluminium ladders sold for domestic use and those sold for trade. Although both types reach the same height, the blurb is very explicit about not using weedy domestic ladders for regular work. Nor would I want to own a 'quality' trade ladder; for occasional use I want a light ladder that doesn't cost a fortune.

I'm recreating Stan's design in Fusion 360 to see if I can get a FEM analysis to work. It's challenging my Fusion skills! However, the attempt highlighted a useful feature of Stan's design. Welding the adaptor plate as he describes simplifies construction.

Dave

7 August 2018 at 13:32 #366104Ian Austin

Participant@ianaustinGood point, Richard. That greater safety factor does bring the theory much more in line with the practice. Ta.

Dave, I hope you're going to give us screen shots of that FEM analysis! Love to see it – would be very impressive.

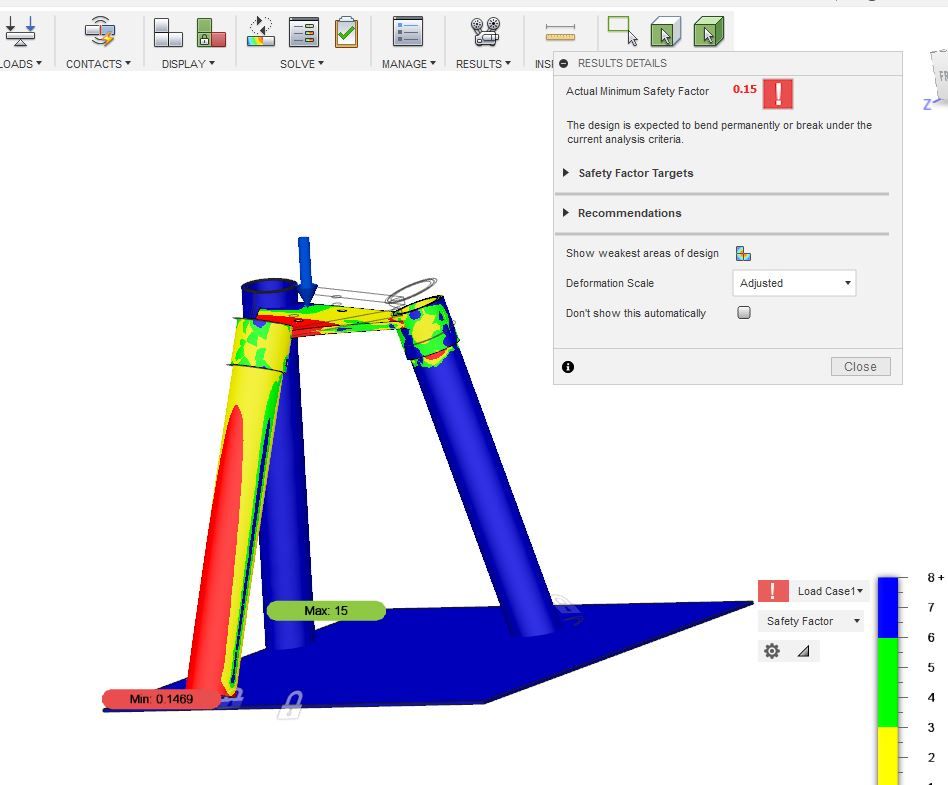

7 August 2018 at 15:53 #366135SillyOldDuffer

Moderator@sillyolddufferPosted by Ian Austin on 07/08/2018 13:32:25:…

Dave, I hope you're going to give us screen shots of that FEM analysis! Love to see it – would be very impressive.

Well, here it is. I'm sorry to say there are multiple faults with my model, so don't take it seriously:

- The material is AISI 1008, which I think is American for mild-steel, probably inferior to real scaffold pole steel

- The poles are thin walled due to me misreading the article.

- I've twisted and misaligned the tripod legs relative to the adaptor plate.

- The load may be off-centre.

- The grounding of the legs is wrong and misaligned.

- The legs are too short

- My first attempt at Fusion in inches rather than millimetres. The way I entered fractions needs checking.

- I'm very inexperienced with this part of Fusion & FEA generally; misunderstandings galore I expect.

I'll have to have another go at modelling the design; I've got some dimensions wrong, plus the way I modelled the angled tripod legs is suspect. At least one of them is at the wrong angle.

The analysis shows a 10000N (approx 1 ton) load on a badly compromised structure, which models most of the load on one undersized leg. In addition, my virtual version is weaker than Stan's actual design. Despite the mistakes, the tripod doesn't actually fail, though it's close!

I wish I'd started with a simpler example. However, provided you define the model correctly, it's straightforward to specify materials, and apply loads to the structure. Running the analysis is easy. Making sure it's set up correctly is more challenging. The colour coding and numeric output of results seems plain enough – risky bits go red! In more skilled hands, I'm sure the tripod could be modelled properly. As my mistakes all weaken the model apart from leg length, the real thing should be stronger.

Dave

Edited By SillyOldDuffer on 07/08/2018 15:55:43

7 August 2018 at 17:31 #366162duncan webster 1

Participant@duncanwebster1A lot depends on definition of safety factor. I tend to use proof stress as my criterion and apply a safety factor as defined in the BS for cranes. If you exceed the design load by a lot, it could permanently bend but you'd need even more to break it, but for buckling if it goes it goes with a wallop, hence higher safety factor. Was involved in the enquiry after a scissor lift cylinder gave way, not a pretty sight, fortunately no-one was underneath.

7 August 2018 at 22:25 #366208richardandtracy

Participant@richardandtracyWhen doing my stressing, for lifting equipment and the immediate area adjacent to the lift points it's always 4 on yield (or 0.2% proof stress for a material that shows no definite yield ) and 6 on ultimate. The load is always combined with a 10% non vertical load to accommodate swinging of the lifted equipment.

Regards

Richard.

8 August 2018 at 00:53 #366219Ian Austin

Participant@ianaustinPosted by richardandtracy on 07/08/2018 22:25:33:When doing my stressing, for lifting equipment and the immediate area adjacent to the lift points it's always 4 on yield (or 0.2% proof stress for a material that shows no definite yield ) and 6 on ultimate. The load is always combined with a 10% non vertical load to accommodate swinging of the lifted equipment.

Regards

Richard.

Richard, this is good solid info. Can you point me toward a published guideline that mentions these factors? The 'swing factor' could I suppose be modelled by subtracting a further 10 degrees or so from the leg angle (i.e. 'flatter' tripod, less strong). Do you think?

Duncan, yes good point, the risk is that an overloaded or defective tripod — or one that someone heavily knocks into — might give way by sudden buckling without the warning signs of previous gradual deflection. So a high SF makes sense.

Dave, looks promising. It would be interesting, when you get it properly set up, to apply a point load midway up to one leg to simulate an eccentric loading, just to see how vulnerable the structure is to being hit either by a swinging load or by someone slightly backing their truck into it.

8 August 2018 at 08:42 #366228duncan webster 1

Participant@duncanwebster1Richard, this is good solid info. Can you point me toward a published guideline that mentions these factors? The 'swing factor' could I suppose be modelled by subtracting a further 10 degrees or so from the leg angle (i.e. 'flatter' tripod, less strong). Do you think?

BS2573, Rules for the Design of Cranes. There is a new one whose number I can't remember because we didn't work to it (2573 still in force when I was still working). There is also one for runway beams. The factor not in the BS is allowable total deflection, which I seem to remember was 1/600 of span for beams supported both ends and 1/400 for jib cranes. Public library should be able to get hold of a copy, it's still copyright so I can't offer to scan mine

8 August 2018 at 09:41 #366235Ian Austin

Participant@ianaustinDuncan, that's great. So following the BS standard for ultimate factor of safety set at 6, Euler's analysis does a pretty good job of predicting a commercial load rating for a hoisting tripod, after all. That sequence I posted earlier just needs SF=6 and the result is 1400kg. It's a more realistic result. Just need to make one and test it at 125% rated load (is the 125% requirement also BS or just ANSI?) — if it keeps standing, it's good. Still not quite sure of the correct way to test the 10% side load though.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Workshop Tools and Tooling › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Install & commission of a Chester Cub 630 (Warco GH750)

1

2

3

Started by:

Calum in: Manual machine tools

- 22

- 73

-

21 August 2025 at 11:01

John Hinkley

John Hinkley

-

F360 stock from solid

Started by:

Roderick Jenkins

in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

Roderick Jenkins

in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 9

- 16

-

21 August 2025 at 10:44

Roderick Jenkins

Roderick Jenkins

-

The stand alone weight for tower clock

Started by:

dk0 in: Clocks and Scientific Instruments

- 9

- 25

-

21 August 2025 at 10:35

dk0

-

Granville lathe leadscrew change wheel

Started by:

JACK SIDEBOTHAM in: Help and Assistance! (Offered or Wanted)

- 7

- 9

-

21 August 2025 at 10:26

JACK SIDEBOTHAM

-

Solar panel

Started by:

duncan webster 1 in: Electronics in the Workshop

- 6

- 8

-

21 August 2025 at 09:40

Stuart Smith 5

-

Phone Phreaking

Started by:

Michael Gilligan

in: Clocks and Scientific Instruments

Michael Gilligan

in: Clocks and Scientific Instruments

- 10

- 11

-

21 August 2025 at 09:18

Chris Crew

-

Asong power feed?

Started by:

Hollowpoint in: General Questions

- 2

- 2

-

21 August 2025 at 08:46

Peter Neill 1

-

Harold Hall – 1933 -2024

Started by:

Neil Wyatt

in: Website Announcements

Neil Wyatt

in: Website Announcements

- 14

- 19

-

21 August 2025 at 00:07

Michael Gilligan

Michael Gilligan

-

Manual for Warco GH750 or Chester Cub 630

Started by:

Gavlar in: General Questions

- 7

- 16

-

20 August 2025 at 22:54

peagreenpete

-

Softening epoxy

Started by:

John Haine in: General Questions

- 14

- 20

-

20 August 2025 at 22:19

Vic

Vic

-

Greatest Model Engineer

Started by:

Juddy in: The Tea Room

- 17

- 24

-

20 August 2025 at 21:41

Nigel Graham 2

-

Material advice

Started by:

tobyonekenobi in: Materials

- 4

- 7

-

20 August 2025 at 20:34

tobyonekenobi

-

Cheap DRO

Started by:

Steve355 in: General Questions

- 11

- 24

-

20 August 2025 at 20:22

bernard towers

-

Drain Cock search

Started by:

Speedy Builder5 in: Locomotives

- 3

- 5

-

20 August 2025 at 20:20

bernard towers

-

Raab Style Heibluftmotor

Started by:

JasonB

in: Miscellaneous models

JasonB

in: Miscellaneous models

- 3

- 6

-

20 August 2025 at 18:50

JasonB

JasonB

-

Reference lines for dimensions – Fusion 360

Started by:

John McCulla in: CAD – Technical drawing & design

- 5

- 16

-

20 August 2025 at 14:39

blowlamp

-

Use of Hydrostatic lubrication in steam locomotives

Started by:

Greensands in: Locomotives

- 6

- 15

-

20 August 2025 at 14:13

Dave Wootton

-

Opposed Piston Engines

1

2

Started by:

Richard Simpson

in: The Tea Room

Richard Simpson

in: The Tea Room

- 13

- 30

-

20 August 2025 at 09:42

Howard Lewis

-

Making Unimat DB/SL Steadies

1

2

Started by:

Andy Carlson in: Workshop Techniques

- 12

- 40

-

20 August 2025 at 09:25

Michael Gilligan

Michael Gilligan

-

Steam driven air pump for brakes

Started by:

Werner Schleidt in: Locomotives

- 10

- 19

-

20 August 2025 at 08:05

Werner Schleidt

-

End Mill Sharpening Jig

Started by:

Vic

in: Workshop Tools and Tooling

Vic

in: Workshop Tools and Tooling

- 6

- 9

-

19 August 2025 at 23:02

Nigel Graham 2

-

Horwich Crab

Started by:

Michael Foster in: Locomotives

- 2

- 2

-

19 August 2025 at 22:17

Dave Wootton

-

Kuroda Boring & Facing head

Started by:

Oily Rag in: Workshop Tools and Tooling

- 7

- 13

-

19 August 2025 at 20:49

ryan.carter848

-

Any suggestions

Started by:

Vic

in: The Tea Room

Vic

in: The Tea Room

- 6

- 8

-

19 August 2025 at 17:53

DMB

-

New Compressor

Started by:

Andy Brocklehurst in: General Questions

- 16

- 23

-

19 August 2025 at 17:13

not done it yet

-

Install & commission of a Chester Cub 630 (Warco GH750)

1

2

3

-