Here is the context driving my interest in the matter. It may be helpful to the discussion to mention it.

My workshop functions around Schaublin W20. There are two 102 lathes which use W20 collets and chucks (M37.6 x 3 spindle thread). My milling machine also uses W20 collets, and its accessories accept W20 collets and lathe chucks. The Ceriani is the only lathe I know of that is available with this spindle option. Even if I found a Schaublin 102-VM or 102N-VM, getting it into my basement shop is not in my future.

One of my 102's is set up for thread cutting. It uses a watchmakers' type telescoping shaft to drive the top slide. There are a few issues that are less than ideal. The longest thread I can cut is 70 mm without having to move the compound slide and pick up the thread again. The cutting tool advancement is only able to be advanced straight in (90 degrees) to the work.

The final issue that an engine lathe such as the Ceriani would alleviate is longer turning operations. Anything longer than 150 mm requires the compound to be moved laterally along the bed. Then the cut must be accurately picked up at the same diameter. Here is an example: a drawbar I made.

Hence, the main focus for another lathe in my shop is turning and screw cutting longer diameter work. To a lesser extent, it would also allow faster, simpler threading operations. When feeding a cutting tool directly in during threading operations is problematic, an engine lathe would be a useful option.

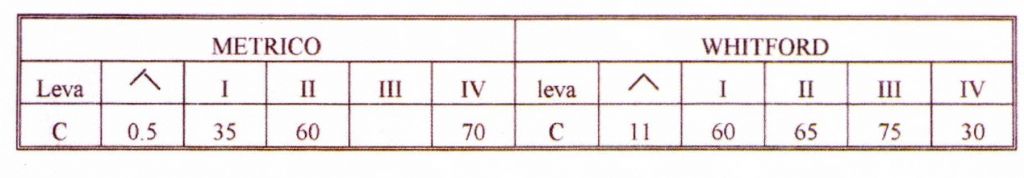

While most of my work is metric — as is my preference — it seems inch threads are required often enough to warrant the attention to accuracy. To a far lesser point, I also like that the Ceriani is truly metric on its cross slide, top slide and tailstock screws. I am in North America, and finding a native metric hobby lathe is very limiting. (Yes, a DRO is an option here)

Having a lathe that is native W20 would mean work could be transferred in one chucking between lathe/lathe or lathe/mill. Being able to use my existing array of collets and lathe chucks is practical too.

Those are the draws that keep bringing me back to considering the Ceriani David. I've always found myself, though, a little underwhelmed by its draw. I don't know what to say beyond that.

Edited By MyrtleLake on 12/04/2016 21:05:34

JasonB.

JasonB.