Hi Muzzer

First the warning – I'm a hammer yielding mechanical engineer; the finer points of CNC control are certainly beyond me, so I arrived at a working solution by good luck and perseverance rather than skill !!

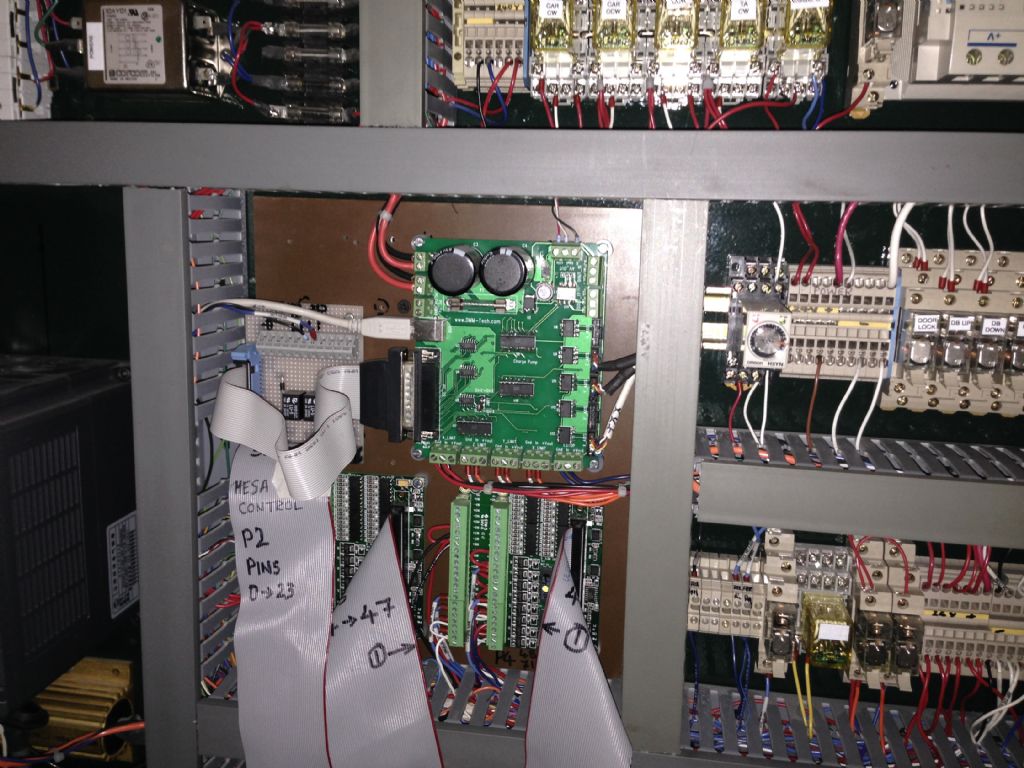

So to answer the MESA question, I don't use either to control the motors. I used the DMM controller board for the motors and the emergency stop and fault functions, which seemed an easy first step, plus a Mesa 5i20 inside an old HP Pentium computer feeding a couple of MESA 7i37's for the rest of the i/os.

I suspect using the DMM board, which uses DIR and STEP is doubling up on some of the capabilities of the 5i20 and probably compromising the performance, but it works really well for me, so I don't really understand it so have not tried to optimise it – let sleeping CNC machines lie is my adage.

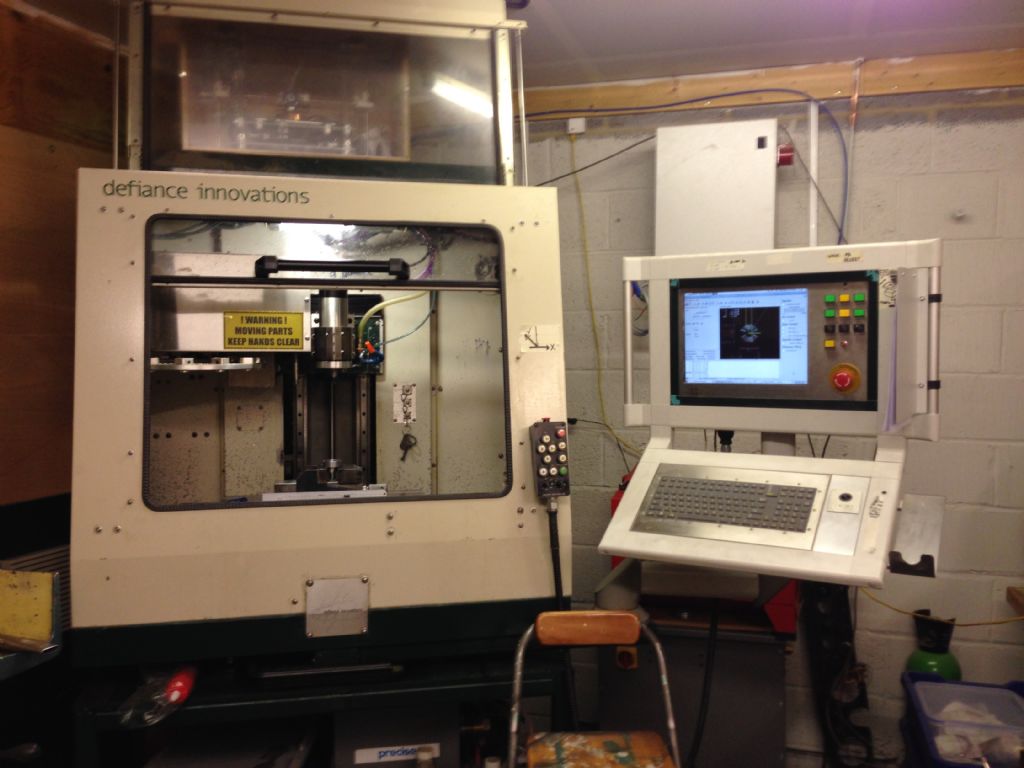

The base machine was a Defiance Innovations small high speed CNC mill, an American company that went under in the early naughties, so no support and next to zero information is available. It was a capable machine originally, fitted with some good stuff, but I ended up replacing the motors, all the control system and even the spindle (field burned out, so perhaps one day I will have it rewound and get auto tool change back) plus totally rewiring. OK, I admit, it was mostly for the fun of it.

The photo below shows the machine (note this morning I removed one of the bellows for repair as it had become torn and I am paranoid about keeping motors dry now).

The nice thing about the Defiance is it's an accurately built machine with proper ball screws, slides and lubrication and even with the refit it is cutting very accurately. I run it quite slowly though, with the maximum velocity at 500mm/min and generally cut no more than 350, which means that so far I have been able to run it off a 13A domestic socket without having to put a bolt back in the plug fuse holder ***

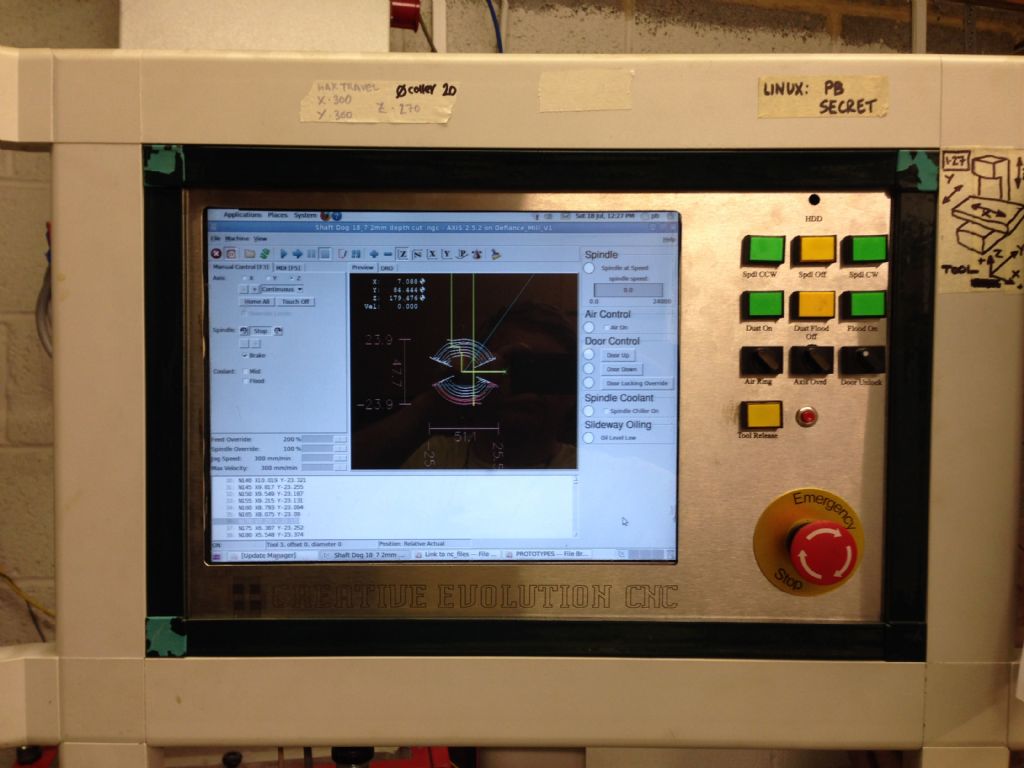

Linux was OK to set up and once I'd got my head around how the program was structured, the I/Os were straight forward to add. You are more than welcome to have set up files if you want them.

Using the machine is easy – I also use Fusion 360 to do the CAM bit and it writes G code in almost perfect LinuxCNC without any code manipulation, unlike another big CAM system that I previously had access to. I never leave it running alone, but It's got to the stage where I trust the code and I'm so confident I don't normally do a dry run of new code, just let it go straight into cutting metal. You watch, later today, having made that claim, I'll plough a big jagged channel into the bed …

Lastly, I am aware that I still have not got adequate fault protection and it's surprising how many IOs are required for a half decent set-up. Obviously the DMM board has a watchdog and other fault protection, but I still need to be more clever on the spindle side. If this stops rotating for any non obvious reason, I will be caught out and the Chinese spindle does not have sensors as did the original. I am starting to work out what signals I need from the VFD to catch more faults, which I will sort shortly.

Cheers Will

*** DEAR SAFETY ELVES, ONLY JOKING ABOUT THE BOLT, HONEST

Muzzer.