First time posting here but have been silently following the forum for years.

Its 2019 now and several cheaper options exist for DROs. You just need to shop around. Ebay, AliExpress, etc.

Magnetic DRO packages are a lot cheaper now than they used to be a few years ago. (I am not talking about digital linear scales here but the actual magnetic scales here).

I always wanted a DRO set for my SX2P and SC2 but the size of the cheap digital scales or glass scales always put me off. But magnetic scales have a much smaller sized head and are easier to mount in tight spaces and offer almost negligible loss of travel or interference with machining activity.

LittleMachineShop has guided instructions somewhere on their website describing the optimal way of mounting it a Sieg Magnetic DRO scale to a mini lathe or a mini mill.

One of my local Sieg re-sellers had the Sieg magnetic reader heads on sale for a attractive price and I quickly bought 2 along with magnetic scales. They are out of stock now else I would have bought a few more for the SX2P Z axis and the SC2.

The magnetic reader heads had information for the various coloured wires as follows:

Yellow=A, Brown=B, Grey=Z, Red= 5VDC and White=0V

After some searching on the web I realized most of these scales have the same generic dimensions, 5 micron resolution and supported 5V TTL/RS422 signal connections.

You can find the same generic magnetic read heads sold under various brand names all over Ebay/Aliexpress.

Once I had the magnetic reader heads and scales, I started shopping around for the DRO display unit or the bluetooth tablet based DRO display option.

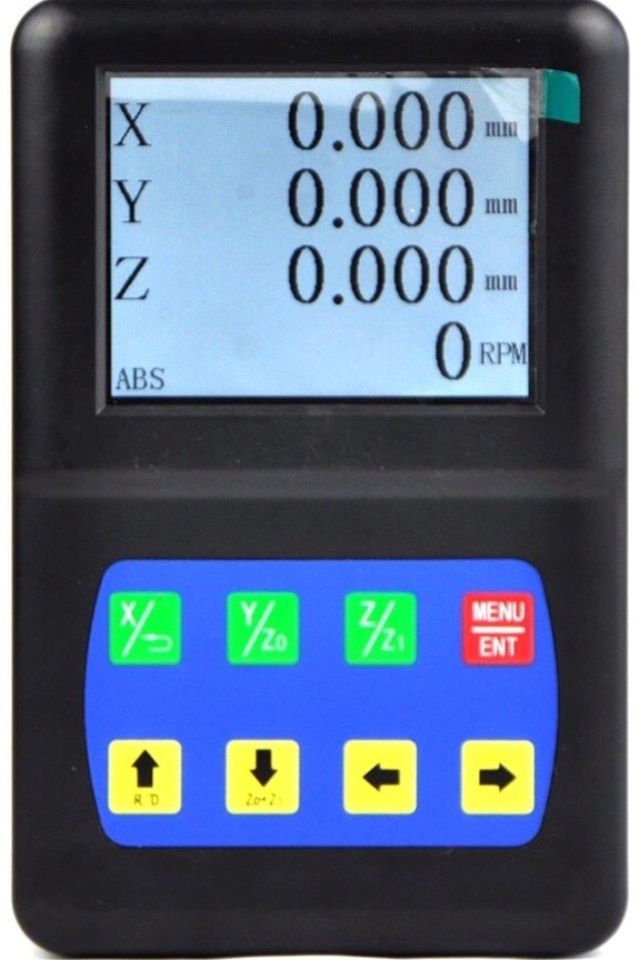

I found a Ditron D50_3V dro unit for a reasonable price on Aliexpress. It supported reading the same 5V TTL/RS422 signal but required DB9 pin serial connectors.

I then bought a pair of no weld DB9 connectors to wire the magnetic read heads with the DRO display unit.

The wiring sequence I used is: Yellow=A= Pin 6, Brown=B= Pin 8, Grey=Z= Pin 9, Red=5VDC= Pin 7 and White=0V= Pin 2.

After some quick setup of the DRO display following the instruction manual, the setup worked.

Overall the above mix and match setup was a bit of a risk but only costed me around A$ 350.

I have not mounted the DROs on my SX2P yet but I am happy with the quick tests.

Terry Howlett 1.

I guess that choosing to do it again shows what we think of it.

I guess that choosing to do it again shows what we think of it.