Posted by mark smith 20 on 29/10/2016 16:56:11:

Thanks Neil, i have alot to think about now.

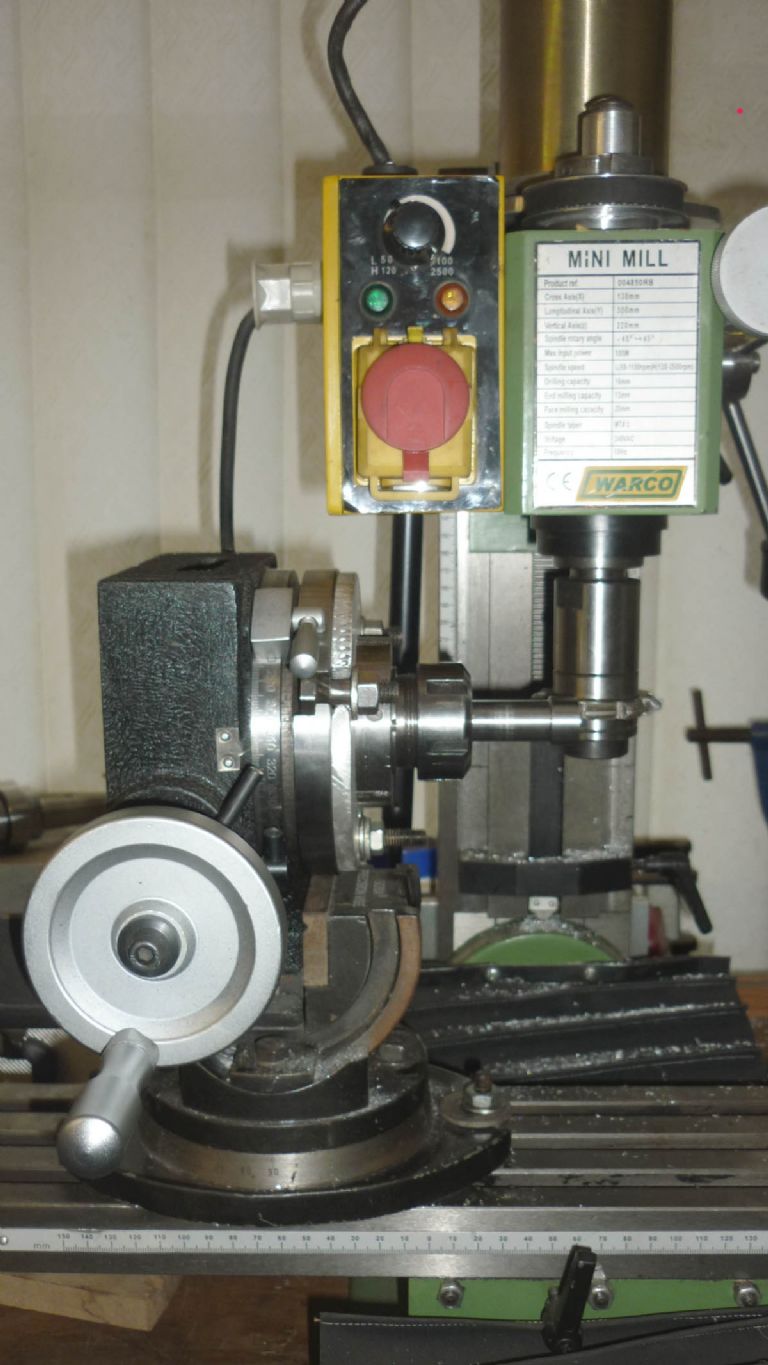

Discovered i couldnt quite mounted the table securely and havent any clamps suitable ,so set it up in the vice like picture , will this work or too unstable . I tested the cutter on some aluminium and it worked fine ,full depth with little vibration.

Problem now is im finding it hard to see the dials due to the position of the set up. It will have to wait till tomorrow now.

Edited By mark smith 20 on 29/10/2016 16:58:02

I dont want to rain on your parade but the rigidity of the whole setup is suspect.

For a start, since you have a milling machine you could make whatever is needed to mount the RT direct to the bed. Another issue is that the cutter is a long way from its bearings, Also the job itself has more overhang than ideal.

The table bearing in RTs are generally pretty basic and some appear to rely mostly on gravity to keep the one main load bearing surface in contact.

Regardless of the size of the mill, the less you have to raise the head of the milling machine the better, yours is only a small machine and it has the extra flexibility introduced by the column tilt feature.

Ian P

Michael Gilligan.

Michael Gilligan.