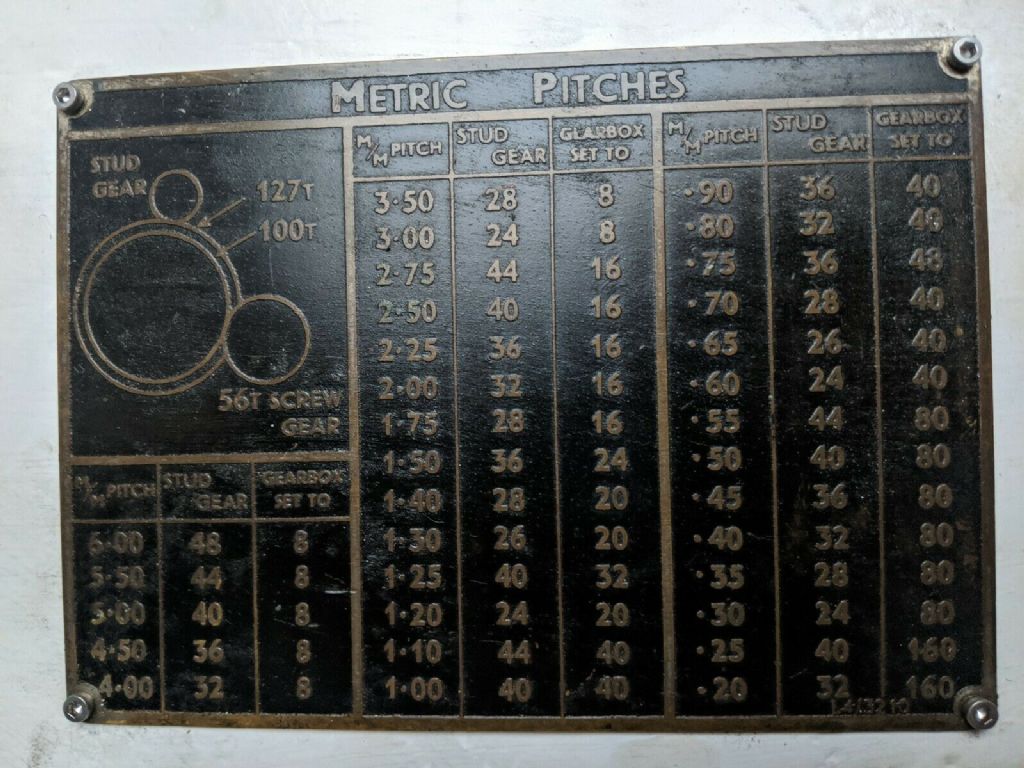

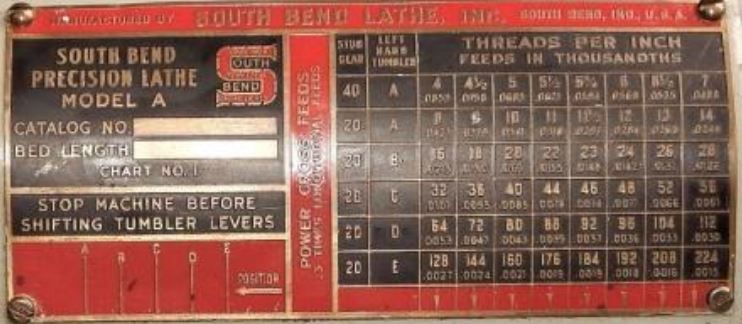

Somewhere there should be a diagram similar to this, either on the lathe or in the manual you probably don't have.

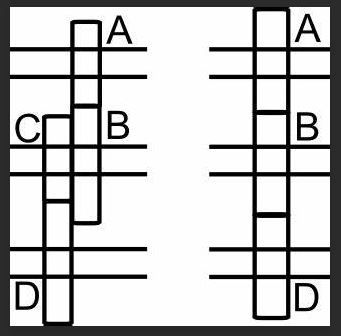

This not too clear diagram is a side view of the change gears. A is your stud gear, B is your 127 tooth gear, C is your 100 tooth gear and D is your 56 tooth screw gear. The left hand illustration shows the setup for metric thread pitches, the right hand illustration shows the setup for imperial threads per inch settings. In the right hand setup the B gear is an idler and so the tooth count is not too important, I suspect that if you have the 20 tooth stud gear in then the 127 tooth gear will work as an idler. If you had a 40 tooth stud gear then you may find you need to use the 100 tooth gear as an idler.

Anyway, from the gearbox plate we see that to do an 8tpi thread we need the stud gear (label A above) to be 20 teeth. We need the left hand gear selector to be in position A and the right hand gear selector to be in the leftmost position.

From the gearbox label we can see if we just change the left hand gear selector progressively through positions A, B, C, D and E we double the tpi count with each move. This means we are halving the lead screw revolution (relative to the spindle) with each move towards the right. This is quite typical for a lot of lathe gearboxes with two gear selectors. One selector has this halving/doubling action. The right hand lever has gears with a tooth count in ratios of 16, 18, 20, 22, 23, 24, 26, 28. We can tell this because just changing the right hand lever produces threads with these counts going from left to right on the third row. The actual number of teeth may be double this. This combination of change gears and 2 ratio selectors gives all the threads you are likely to need but is not comprehensive, BA threads for example are not included.

I don't know if you have a thread dial indicator but luckily for you an 8 tpi thread and an 8 tpi leadscrew means you can engage the half nuts anywhere on the leadscrew and be in the correct position for multiple passes to cut the thread.

Martin C

Jim Beagley.