I have a 1 Tonne arbor press and have no problems broaching metal of any size, You just need to remember to graduate the cut with bigger sizes, the same way a gun barrel was traditionally rifled by shimming the height of the cutter (albeit in a more complex mechanism).

Often times i use the arbor press to get it started square to the barrel with the appropriate collar, and if i run out of room i place the workpiece in a vice and finish the cut with a hammer, its pretty safe and it works so long as you don't hit like a madman but please dont take that as the gospel.

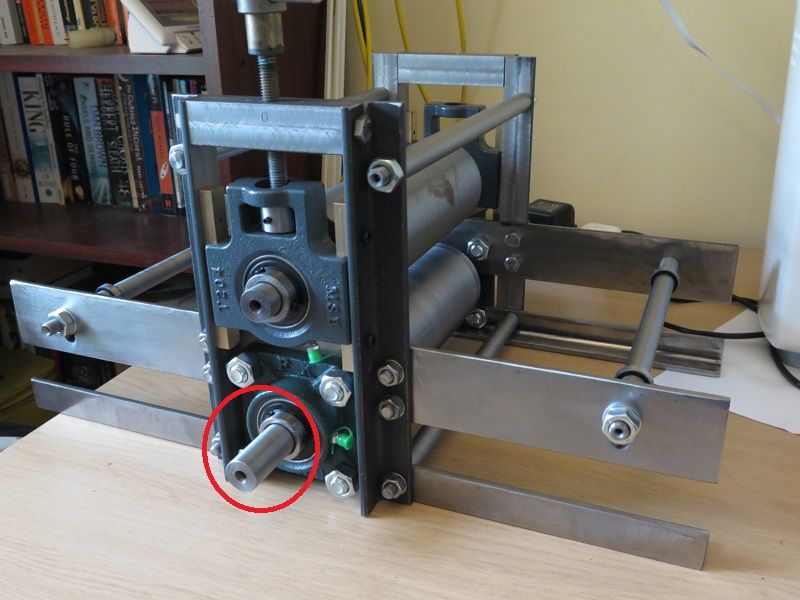

Ps. I see the image of the work piece you have kindly loaded, I can see why you would want to keyway that, may i recommend that you actually make that whole shaft square? You either file or broach the female part square and it would absolutely hold fast, it's a bit more difficult but the choice you go with will probably be the most sensible one and easier route of broaching a round shaft.

Michael W

Edited By Michael Walters on 27/03/2016 17:42:47

Anonymous.