I've got a SIEG mini mill (SX2.7) and have recently been struggling with machined features ending up ~ 0.1mm off center (shifted towards the column) even though they were carefully picked up with a dial test indicator or a wobbler + DRO.

I then checked the column squareness and let's just say it wasn't square so the center picked up at 200mm would not be the same after lowering the head to make the cut. This issue is still not fixed but it's not what I want to ask about.

While troubleshooting I started checking the head movements with an indicator and discovered that when using the head lock, the entire thing would tilt up by as much as 0.12mm measured at 50mm distance. That's obviously unacceptable as squaring the column will be pointless with the head and therefore spindle being off anyway as soon as I use the lock.

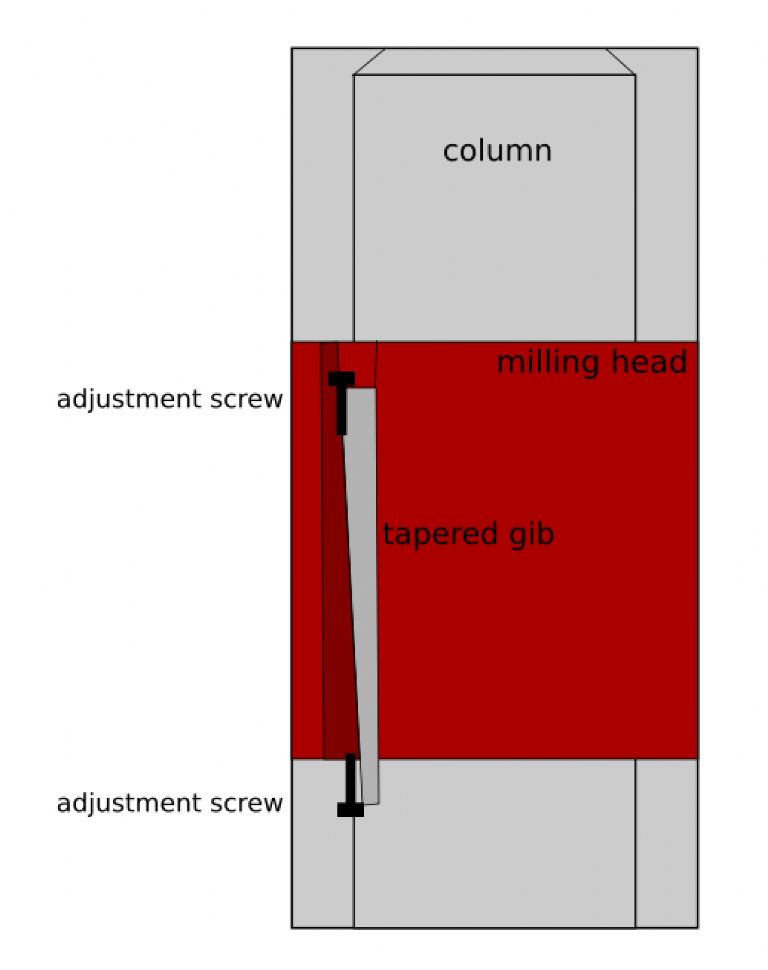

I then tried adjusting the gib but it was already sitting quite hard. I put a piece of wood under the head, lowered it and removed the gib and both the adjustment screws. I cleaned it and put it back in without the screws. I then found out that the gib can be pushed almost all the way through, way beyond the adjustment screw travel, see drawing:

Am I not getting how a tapered gib should work or is already that worn after a few dozen uses, maybe it was bad from the beginning? In my understanding the bottom screw is there only to prevent jamming, and not stop it from falling out, the taper should do that.

I'm considering making a new gib, but before I go for that I want to make sure there is no simpler way. I tried searching for information about tapered gibs, but it's very sparse. I checked the MEW index and I don't think it was ever covered?

Piotr.