Martin,

Can I suggest you do the following?

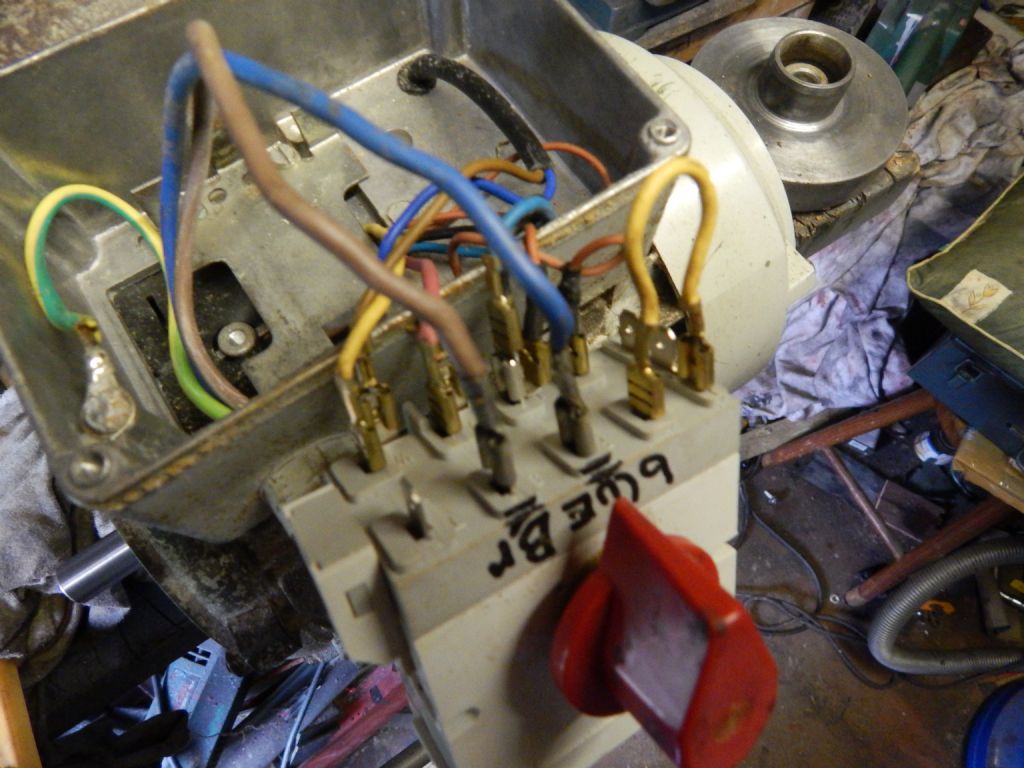

Determine the Main windings wires, these should be connected to the main supply coming in, permanently connected….you can do this by measuring the resistance of the winding, it will be low.

Determine the Start winding, one end will go to the Start cap, the other connected to one side of the Mains wiring. The resistance will be higher than that of the Main winding.

Having determined which winding is which, get the motor to run in a direction whereby it isnt getting hot.

Once it runs in this direction, note which ends of the start winding go where….now swap the connections.

The motor should now run in the opposite way round.

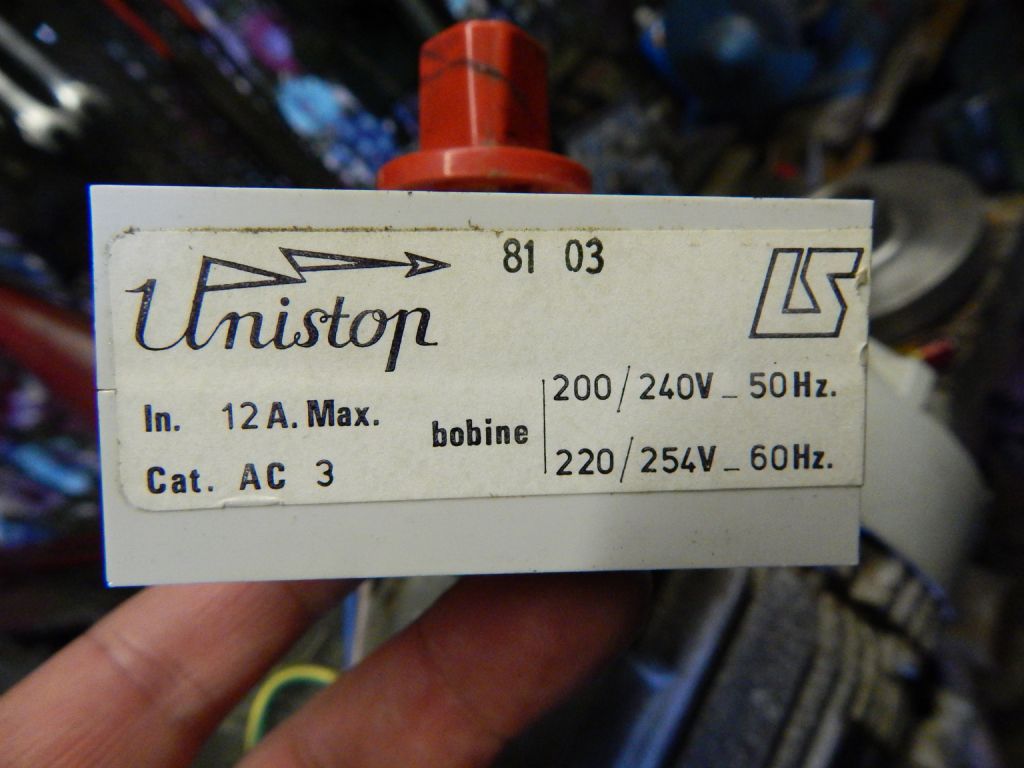

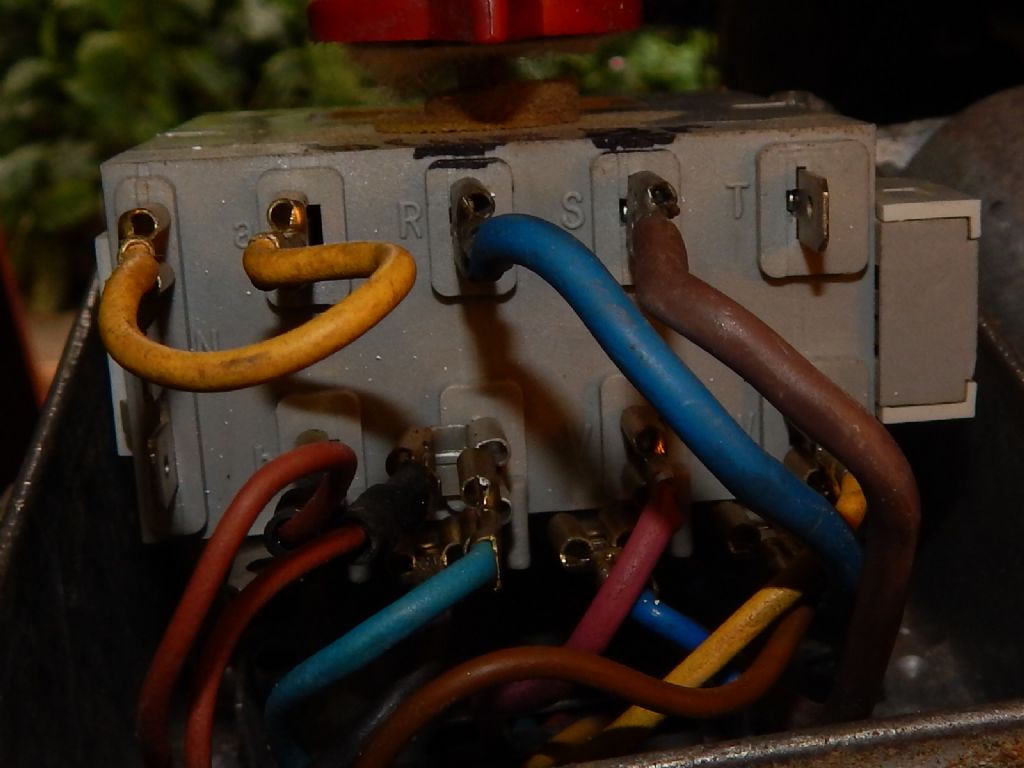

The switch only provides an On-Off function, a double pole isolation switch if you like…. Mains Neutral on one side accompanied by the Live adjacent to it.

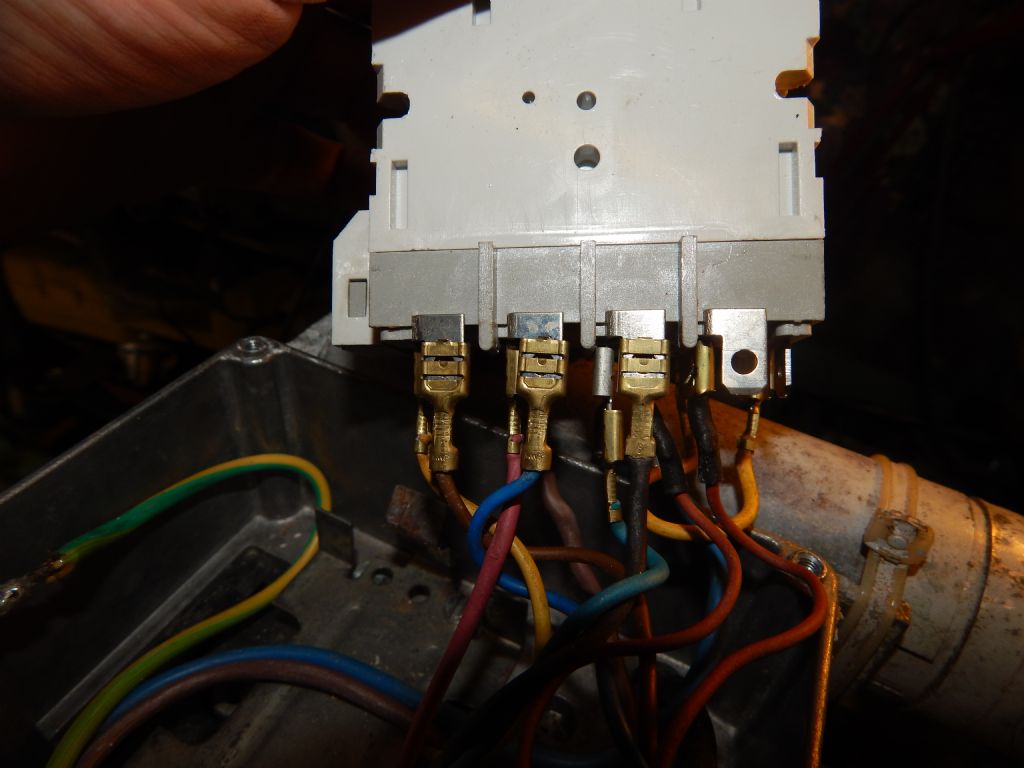

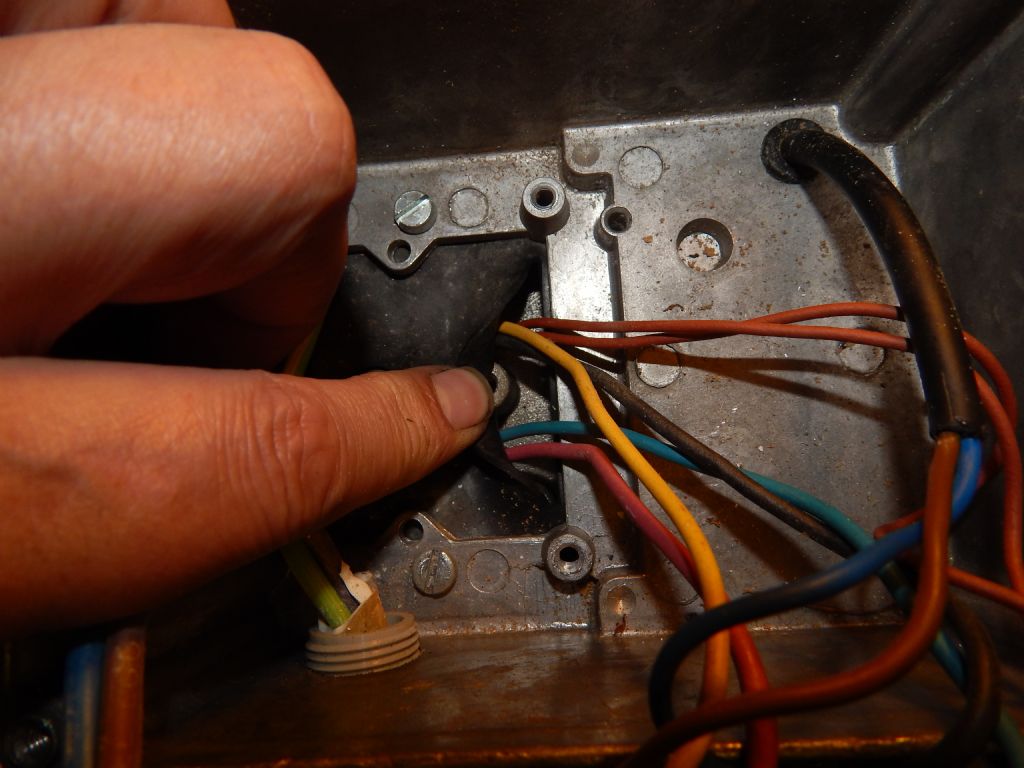

On the other side, you should have 1 wire from the Main winding, with one wire from the

start winding both connected to either Live ( or Neutral) .Then the other end of the Main winding and one of the wires

from the capacitor connected to Neutral ( or Live) . The remaining wire from the Start winding should be connected to the remaining wire from the capacitor..

Apologies if this going over old ground, but basics is sometimes better going back to…

Having re-read Martin C's post, I tend to agree that if there is a centrifugal switch inside, it is not going to like running backwards and perhaps this is why it is getting hot….

Edited By John Rudd on 28/06/2016 15:08:44

Neil Wyatt.

Neil Wyatt.