Many thanks to everyone for your replies.

I think the blade is almost certainly the problem, as Jason and others with experience of these things clearly sensed.

I took off the blade used in the video, located the weld seam and emeried it as smooth as I could get it, even though it was pretty smooth to begin with.

After refitting I expected at least some improvement, but there was none; it still jerked downwards disconcertingly. [In the video the jerking and clunking is more noticeable in the last half].

Fortunately, Aldi supply two blades with this saw [M42-grade steel, so perhaps a bit better than bargain bucket territory in their material at least?]. I fitted the second blade. There is a slight detectable deviation downwards once per rev., but this is much less than with the first blade, and there is no audible clunk.

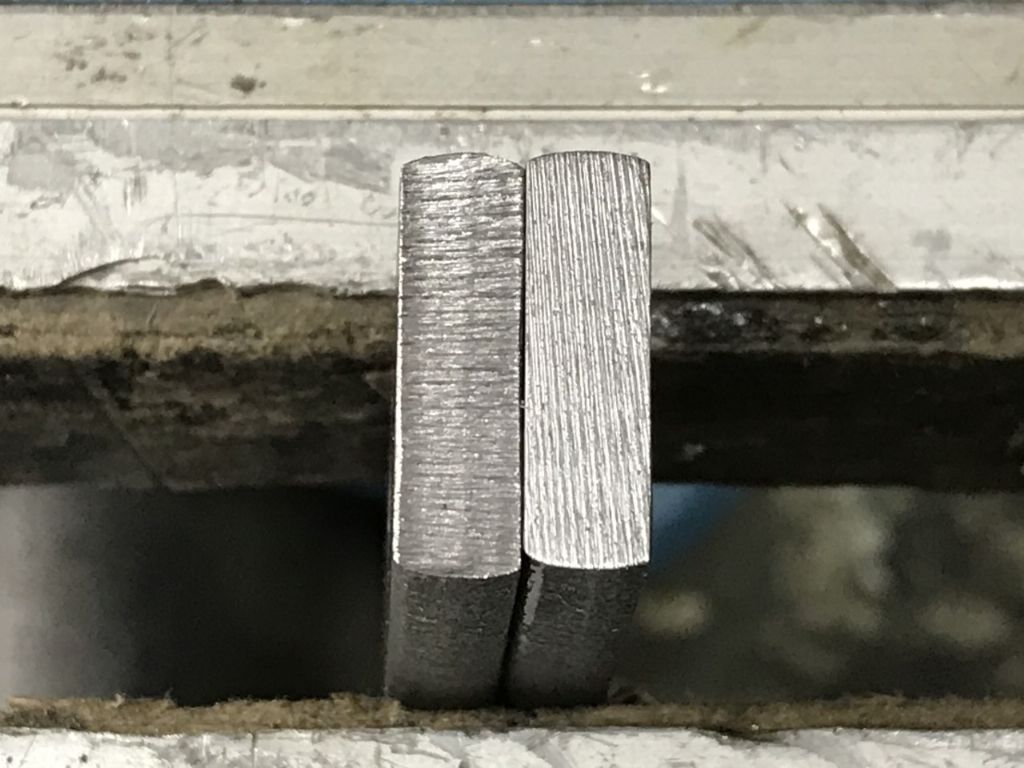

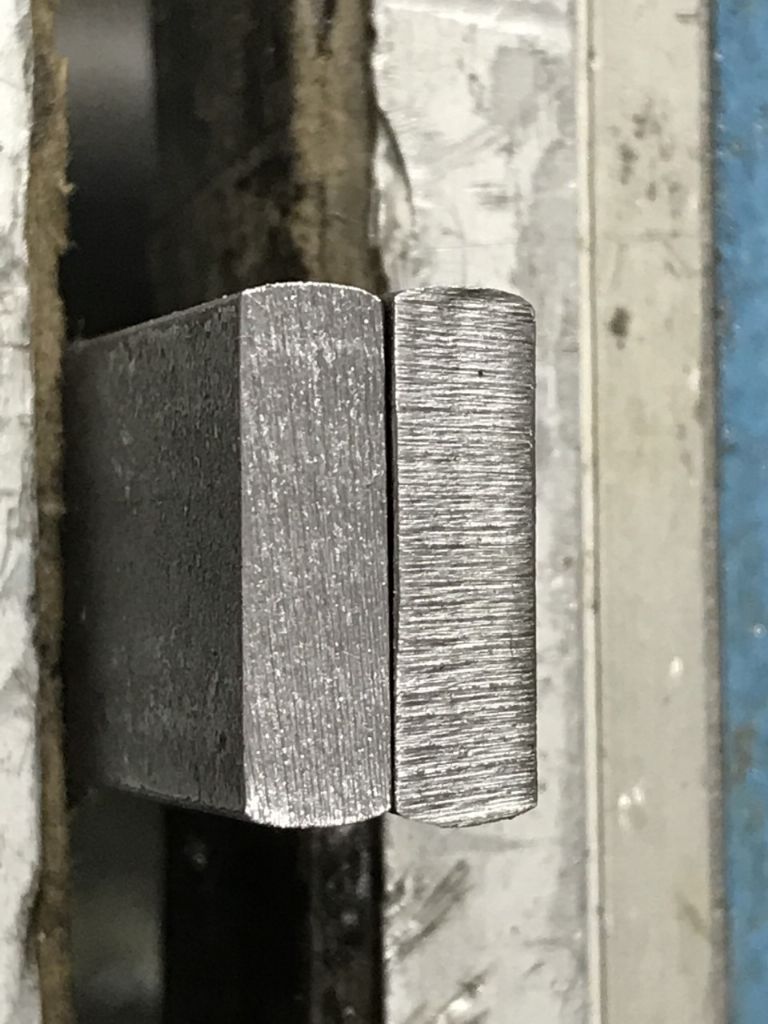

As for cut quality, I've uploaded a couple of photos of steel bar showing the difference between cutting with the bar flat and cutting with it standing on edge, as initially. Lying it flat produces an obviously better cut.

There are still two minor issues. The picture of the brass bar [in the first image and 3/8" x 2", I think] shows the first: the two short patches near each end of the bar. I can't detect any difference in surface height with my finger at these points, so I'm not too concerned by it, but does anyone have a suggestion as to why these markings have occurred? There is nothing on the surface of the bar either side to explain their existence, and further cuts produced exactly the same result. The bar was cut lying flat.

The second issue is that now I have shimmed the vice on one side with washers [around 1.25 mm thick], the plastic guard on the inner side of the saw slightly fouls the angled side of the vice at the bottom of the cut. I can probably resolve this fairly easily, but why the clearance between the edge of the vice and the body of the saw has to be so small I don't know.

John Baron, there are no missing teeth.

John Haine, if you click on the second link in my opening post you should find my post about the Femi on that page.

Ady, the user manual shows the blade tension lever pointing almost vertically downwards when the blade is tightened according to the instructions ["to the stop"]. Are you saying it would be OK to use the saw with the lever backed off part way? I will back it off when not in use.

Robin.