You're overthinking things a bit (a lot) with magnifying glasses and vernier protractors and exact tip radiuses..

Machinists have been cutting fine threads like that for over a century by using a standard, good quality screwcutting gauge (eg M&W), the little sheet metal one with the V notches cut in it.

Yes, for small threads, the very very tip of the tool is in the straight clearance slot in the gauge. But that's no problem at all. If the rest of the side matches the gauge, and the side is straight, the tip must be the same angle.

Secret is to finish the tool off by rubbing it on a bench oil stone, the type used to sharpen kitchen knives etc. Rub both sides of the V on the tool bit on the stone to get it nice and flat and smooth.

And agonising over exact tip radiuses (or radii if you are one of those pedantic types) is the realm of pedantic armchair engineers and what Martin Cleeve describes as "over-zealous amateurs". All you need to do is rub the tip on the bench oil stone a few times with a nice rolling motion, just enough to take the sharp point off. The main reason for doing this is not for thread form — it really does not matter as the point will cut a handy clearance at the root of the thread — but to stop the sharp tip from tearing off under cutting load. No need to measure the exact radius. Just feel it with your finger.

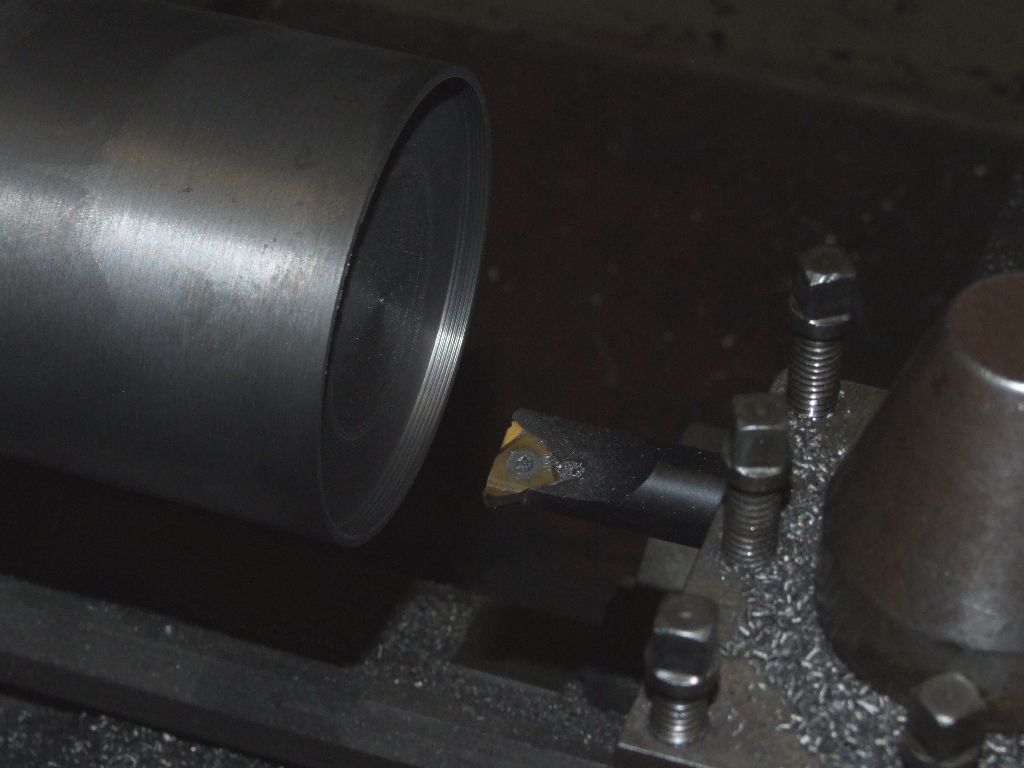

This is the way threads much finer than yours (32tpi is run of the mill average really) have been cut countless millions of times in machine shops since the days of Mr Whitworth and James Watt etc through to the late 20th Century when carbide inserts started to take over. Somehow since then, people have come to think there is something exotic about the shape of a thread cutting tool for general work.

There isn't.

Edited By Hopper on 03/02/2020 01:33:52

Michael Gilligan.

Michael Gilligan.