The easy way is to let the lathe do the maths for you!

1) Assuming the work is already turned to the thread outside diameter bring the tool up to touch the work and set both cross and top slide dials to zero.

2) Move the tool back a touch to clear the work then rack the saddle along until the point is past the end of the work.

3) Feed the cross slide forward past zero by the depth of thread to be cut.

4) Re-set the cross slide dial to zero. The tool point is now at the final depth of cut with both dials readin zero.

5) Pull the top-slide back until it clears the work then move forward to sufficiently to make the first scribe cut to verify that settings are correct.

6) After making scribe cut wind the cross slide back past zero and move saddle back past the end of the work.

7) Re-set cross slide to zero and apply first cut with the topslide.

8) Make first cut and repeat wind back cross slide, move saddle to end of work, set cross- slide back to zero and apply next cut process.

9) Repeat until both dials read zero at the end of the cut and all spring has been worked out. The thread depth will now be what you set in step 3.

If you set the book depth of cut the results will only be correct if the tool tip radius is correct or at least very close to book value. This is rarely the case in a model engineers workshop so it's usually necessary to cut a bit deeper before things screw together. I prefer to apply any extra cuts via the cross slide so when the correct fit has been achieved on either a test piece or the first of several parts I can simply re-set the cross slide zero to match the corrected final depth and all subsequent parts will be correct at zero-zero.

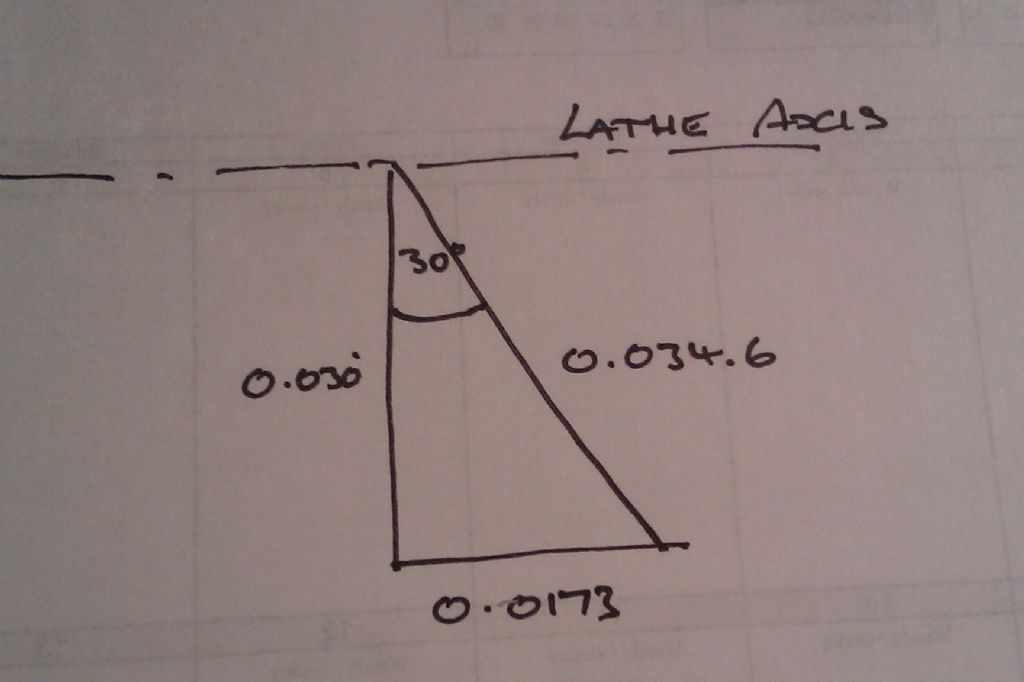

A major advantage of this process over mathermatical calculations it that it works fine for any reasonably sane top slide angle. If calculations are to be correct your set-over angle needs to be closer to correct than is easily achieved with the usual graduations, especially on small machines.

I was taught the method as "zero to zero" also seen it as zero-2-zero and similar variant names can be found by Google search. Geo. H Thomas has also described it both in Model Engineer and in his book "Model Engineers Workshop Manual". I imagine its described in other places. Its so easy and effective that I bemused by it not being the standard textbook way.

Clive

Edited By Clive Foster on 06/02/2014 23:00:19

Edited By Clive Foster on 06/02/2014 23:01:17

ChrisH.