Since my post last week and Jason's helpful tips I have done some dismantling, principally to remove the top cover and motor, which does save a little bit of weight.The dowels in the column bottom seem strange, the hole in the column is vertical whilst that in the base is at an angle, so when you have extracted them, they are bent, go figure. Having said that they went back in with no problem. I also took off a lot of the bits to aid the cleaning process, I can understand why it's necessary but it really is an awful job. I managed to happily lift the head and column off the base and lay it down but I really wouldn't want to carry it any distance.

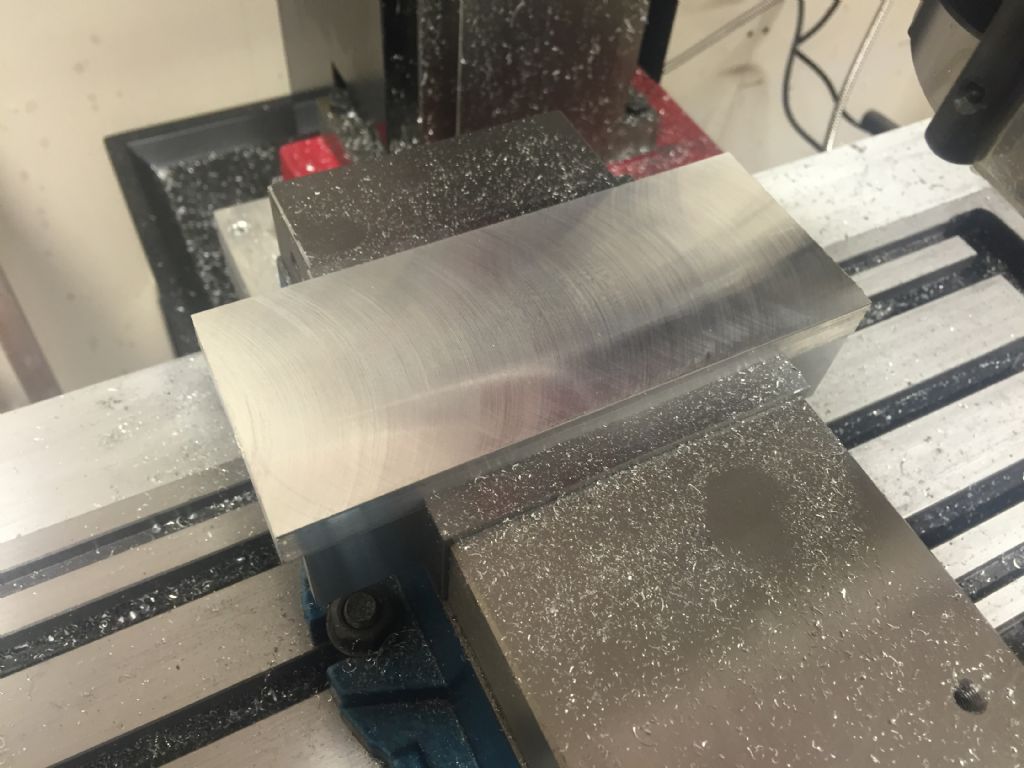

Sunday afternoon was spent very productively cleaning it all, and so yesterday my pal Derek came round. Now he is a typical west of Scotland character, shortish in stature, stockily built and with a major can do attitude, I invited him to test the weight, "nae problem pal, it'll be a scoosh", was his assured response. Actually getting it to the foot of the attic steps was easy enought, thereafter a bit of rope with me underneath it, guiding it to avoid damage and rest on alternate treads worked, it was somewhat nerve wracking, failure would cause major damage to me and the machine. Thankfully we got there, and the base was easy peasy. A picture of the machine on it's bench, which needs some additional bracing, I'm very pleased to have got here.

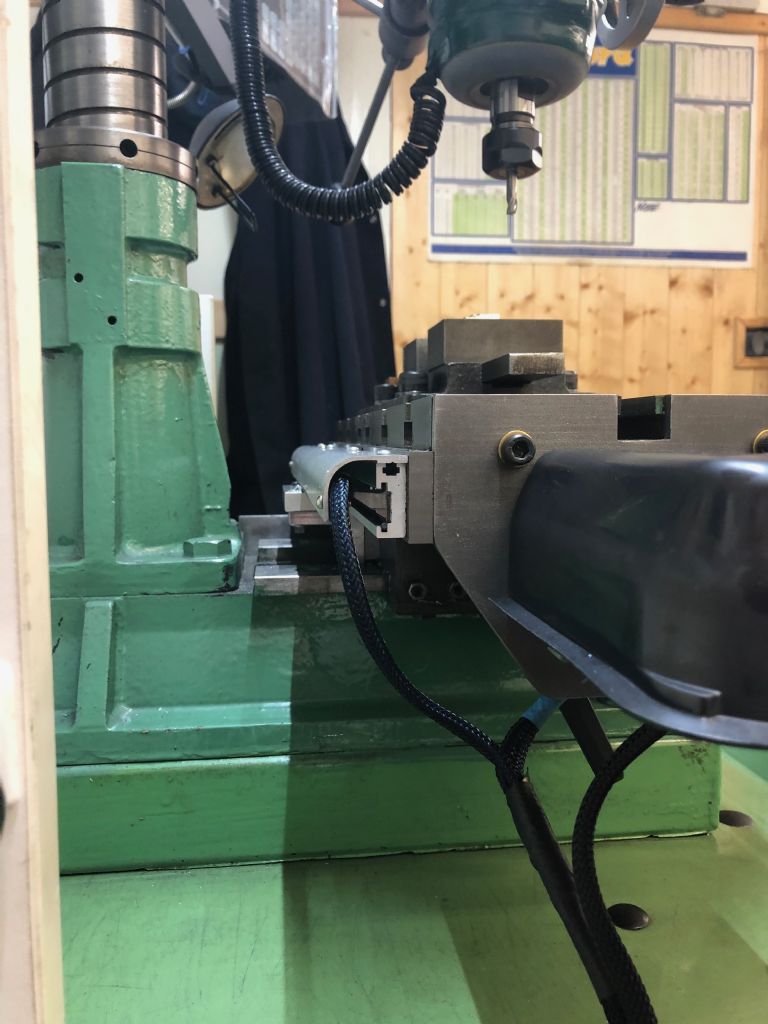

You'll notice I've gone the whole hog and fitted the Sieg X axis power feed, it works although probably not slowly enough for deep DOC in hard material, and to be fair Arc did point this out to me, but even so that's a whole less winding to do. I could I suppose have home brewed something for less money, but ultimately for me the hobby is not about machine tools, they just need to do a job, I can spend the time better.

A couple of thoughts, Sieg haven't improved their painting, the manual is riddled with errors, for example it tells me that the motor is retained by M6 by 14 screws, which in reality are M4 by 12. and that at first impressions it is a fine machine. I hope I have no cause to regret that.

Regards

Martin

geoff walker 1.