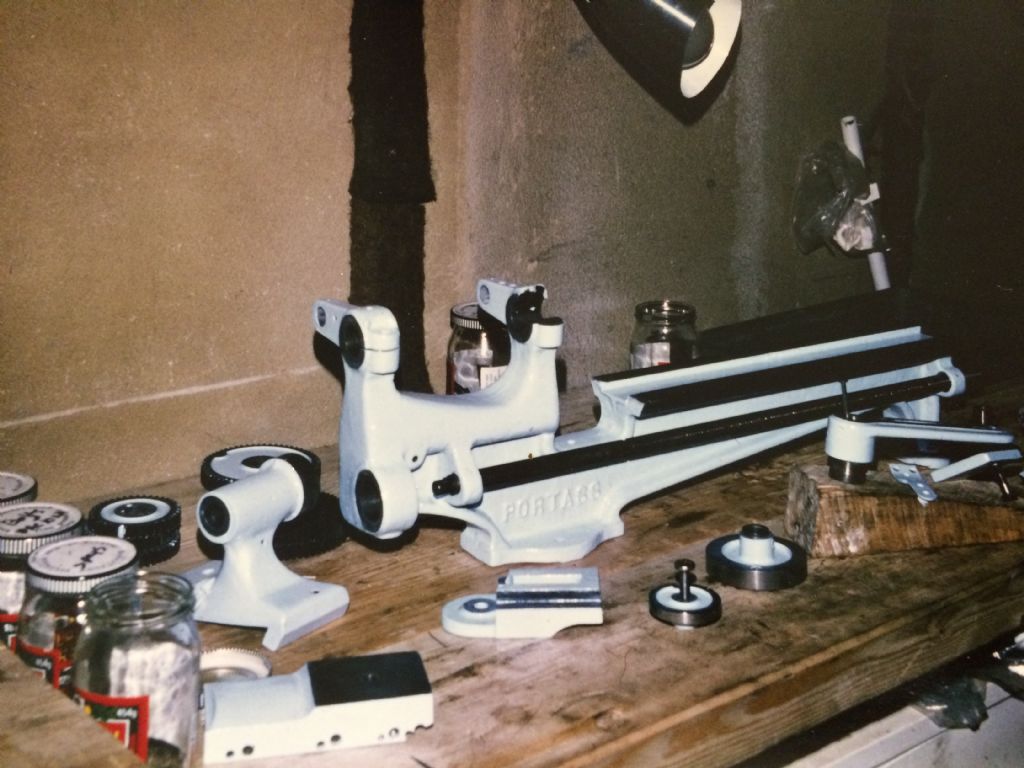

Hi John, Rod could be on the right track. Although the badge RandA didn't seem to be used on production models, I have one where the RandA badge is cast into the bed, however the headstock is a separate casting and is made of bronze or maybe gunmetal. I have no idea if this is how it was made like this at the factory or if someone who had it originally broke the original headstock and had a new one made and fitted it to the bed after cutting the original one off, but it was shimmed up with a W.D. & H.O. Wills Woodbine cigarette packet and a short piece of thin copper.

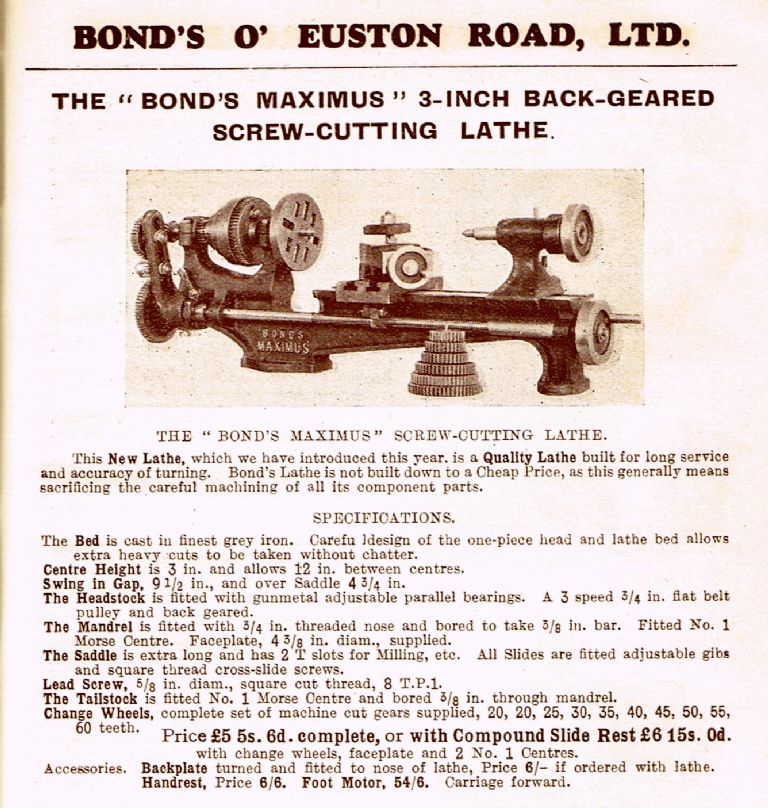

Bond's O' Euston Road did the same model and called it the "Bond's Maximus" which was apparently a slightly modified Portass Model S **LINK**

I have more photos of this RandA I have, so if you would like to see them let me know.

Regards Nick.

P. S. I don't know what year the advert for the Bond's lathe is from, but in the same catalogue castings for a few of LBSC locos where available including "Olympiade" which was described in Model Engineer from July to December 1938.

Edited By Nicholas Farr on 17/10/2015 10:24:41

Muzzer.