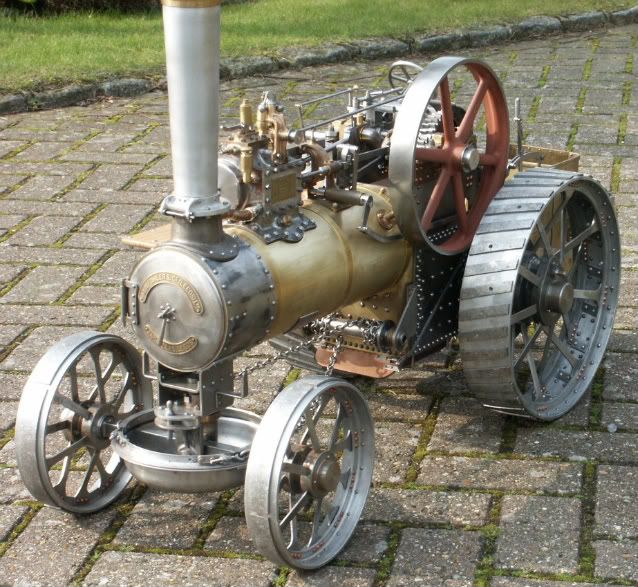

Certainly a big improvement over the previous effort.

Couple of points for future reference.

You have a lot of solder on those joints, any saving you had hoped to make by using 40% solder has been well and truely negated by the amount used. Most likely reason is that you have not got things hot enough for the sollder to flow freely, another disadvantage of 40% is it needs more heat and does not flow like 55%. Combine this with your tight joints and you won't have got it to flow well into the actual joint so have ended up with more of a brazed joint rather than silver soldered.

Another tell tale sight of it not being hot enough is the lumpy surface of teh solder, once properly heated it will flow like a liquid and just leave a very small even fillet.

If you are pickling it enough you should not need to tumble it, just a quick rub with a scotchbrite pad or wire wool when it comes out should have it looking like the first pic of the unsoldered pipe. Also don't try polishing until all soldering is complete.

J

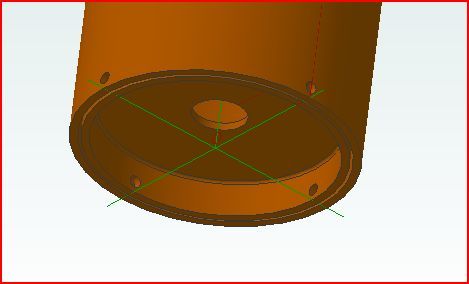

PS make sure you have a valve/feed hole in teh top plate when you come to solder the chimney into place so fumes can get out

MW.