Brian,

On reading your post I went to have a look at one of my Parvalux motors which runs a 'Scotchbrite' mop. I have several of the fractional hp motors with gearboxes, unfortunately not to hand at the moment.

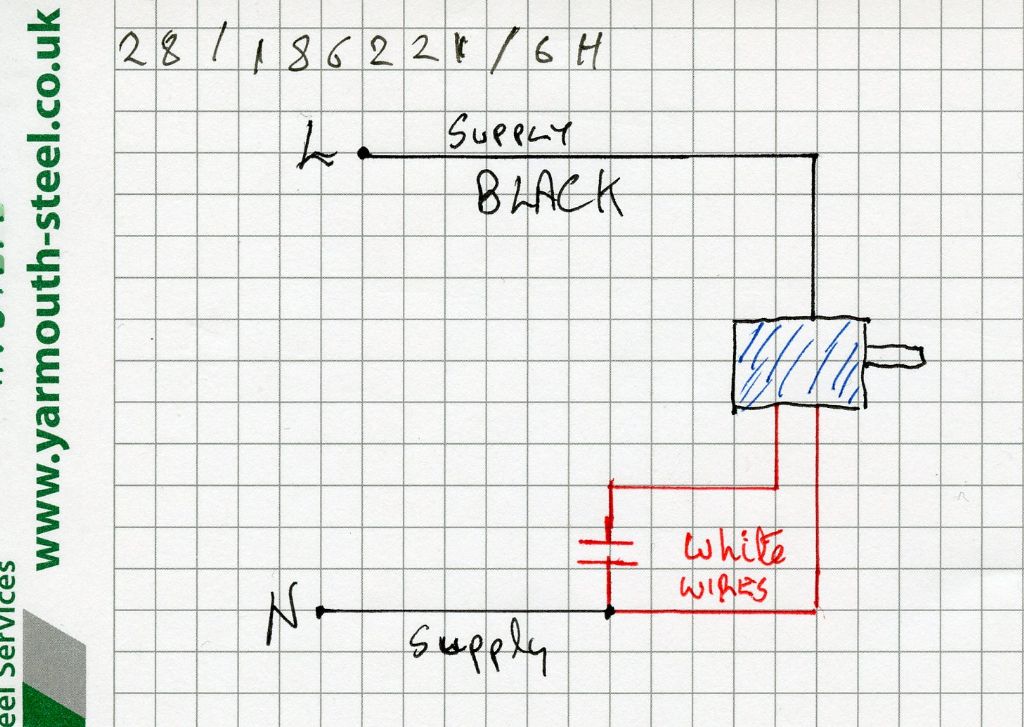

The 'mop' motor is a 240V 50Hz single phase 2800 rpm motor with cap start. The wires within the junction box are, from the motor 2 red and 2 white, the feed into the junction box from the mains is the normal blue, brown, and the earth yellow/green. the capacitor is external and is a 240VAC 50/60Hz 10uFd item.

The connections are as follows:

Mains Blue to White, Mains Brown to Red, whilst the remaining Red and White internal wires are joined together. This leads me to assume it is a 2 pole motor and the 2 poles are in series by way of the Red/White connector. The capacitor sits across the power 'inlet' i.e one side to the mains blue and one on the mains brown. This makes me think it is a cap start / cap run system. There is however a centrifugal 'switch' which can be heard to click in as the motor slows down when switched off. The mains earth connection is grounded to the motor body by a screw inside the junction box.

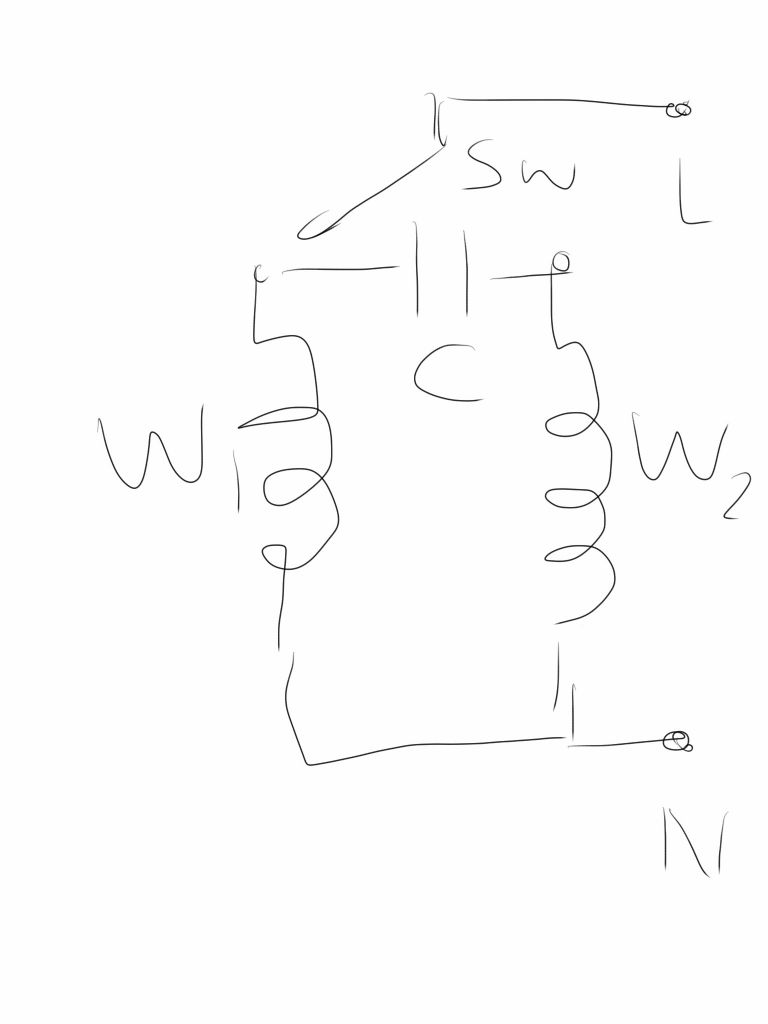

With your 2 smaller wires I wonder if these are 'centrifugal switch' connections for taking the cap out of circuit. hence i would expect them to be wired in one side to the cap and one side to one of the 'infeeds' from the mains. This would presumably make it a cap start only motor.

I will dig out the gearbox motors to see if they are anything like your wiring – from memory they are 1/16hp and the gearboxes give a 12rpm speed. I have another motor without gearbox which is similar to the above but 1/8th hp and is fitted with a 4uFd capacitor.

Can you detail your motor parameters, and a photograph would also help. I would be interested what hp rating it is (or Wattage), motor rpm, and whether it has an external cap.

A Happy (and Healthy) New Year to all,

Martin

Brian Pritchard.