Thanks to everyone for your replies.

My post in this thread:

https://www.model-engineer.co.uk/forums/postings.asp?th=177296&p=2

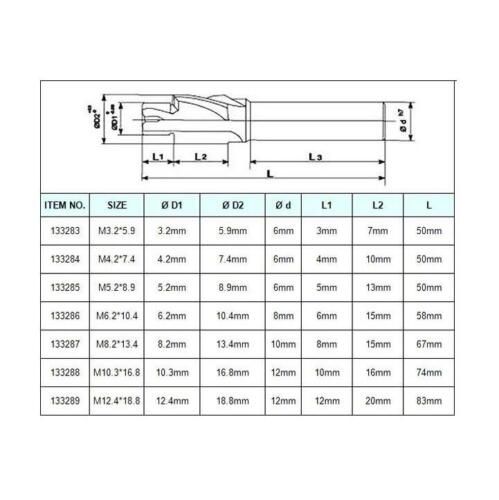

will explain why the DIN433 cheese-head screw washers Jason and others are referring to will not fit my counterbores. The metric counterbores I use aren’t rare anomalies dimensionally speaking but are widely available in the marketplace. Their closer clearances (e.g. 13.4mm for the 13mm head of an M8 cap screw) give a much better appearance, I think, than the standard ones Jason refers to.

Michael’s mention of imperial cap screws led me to look into the relative dimensions of imperial cap screw heads and the counterbores that exist to accommodate them. Obviously what I’ve unearthed in a brief search isn’t the whole picture, but…

Mc-Master-Carr’s 5/16” cap screws have 15/32” (11.90625mm) diameter heads. Mc-Master-Carr’s standard 5/16” counterbores have a cutter diameter of 0.475” (12.065mm). Their 1/64” and 1/32” oversized counterbores, for “when the screw holes in sheets or layers of material are misaligned”, have cutter diameters of 0.491” (12.4714mm) and 0.506” (12.8524mm) respectively.

Hence, with their standard counterbore, a 5/16” cap screw head’s diameter is 98.7% of the diameter of the counterbore.

With the 1/64” oversized counterbore, the 5/16” cap screw head is 95.5% of the diameter of the counterbore.

With the 1/32” oversized counterbore, the 5/16” cap screw head is 92.6% of the diameter of the counterbore.

Now let’s compare DIN 912 M8 cap screws. The head is usually 13mm diameter. Standard M8 counterbores of the kind Jason has in mind typically have cutter diameters of 15mm. This means the head of an M8 cap screw is only 86.7% of the diameter of the counterbore. When measured by the standards of typical imperial counterbores, therefore, these standard metric counterbores produce massively oversized recesses for the heads of cap screws to sit in.

The question is why they are "standard" when they are so oversized?

In the case of the apparently non-standard M8 counterbore I have chosen to use, the head of the cap screw is 97.01% of the cutter’s diameter. This puts it dimensionally about midway between Mc-Master-Carr’s standard and 1/64” oversized counterbores. Isn’t this a sensible sizing decision, far more sensible at any rate than the unaccountably “standard” M8 counterbores with 15mm cutters?

Yes, I can make plain washers to fit, and have done, but the question remains why, when square section spring washers are practically the same diameter as the cap screw heads they are intended for and commonly available, isn’t there such a thing on the market as a plain washer with essentially the same dimensions?

To answer David's suggestion of Schnorr washers, although it seems these will fit my counterbores, I wouldn’t want to use these washers very often, partly because of cost and partly because they may leave gouges on the surfaces of parts, just as spring washers do when you disassemble connections they’re used with.

Bill Phinn.