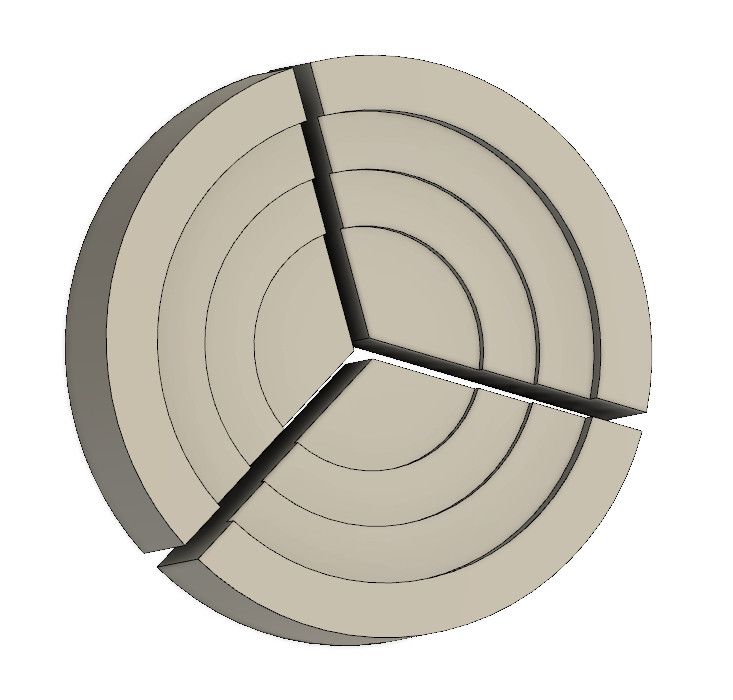

In the U.S. the commonly encountered chucks of this sort come with a 5C collet shank (as Chris Evans notes). The shank may be integral or separate. Hardinge calls theirs "Step Chucks". These have an integral 5C shank. The ones they supply of unhardened steel are called Emergency Step Chucks. You bore to the size or sizes of step(s) you need. Hardinge also supplies these hardened and ground in a variety of sizes, each with only one "step". I get the impression from their website that they are phasing out the hardened and ground ones. The O.D. of the head on these has a taper which is pulled in to a closer which Hardinge makes for either their tapered or threaded spindle nose (they may have these also for type A spindle noses as used on their CNC machines). Monarch did make a set of compatible closers for the D1-3" spindle nose on the 10EE. I was lucky to find on ebay one of these for the 3 inch step chuck.

Another U.S. company, JFK Company, makes a couple of iterations of this. One they call the "Step Collet". It has a steel shank that includes the 5C closing taper and a head to which "pads" either steel or aluminum, are attached with socket head cap screws. One then bores out to the size or sizes needed. They call their other version an "Oversize Collet". Here the head, either steel or aluminum, includes the 5C closing taper. This head then screws on to a back piece of steel which is threaded to fit the 5C drawbar.

There are additional makers of these sorts of 5C collets. They may have their own names as variations on a theme.

David

Edited By David Lindquist on 16/09/2018 02:02:32

Edited By David Lindquist on 16/09/2018 02:03:07

Edited By David Lindquist on 16/09/2018 02:04:14

David Lindquist.