Neat way of doing it, Nick. Thank you for the tip.

'

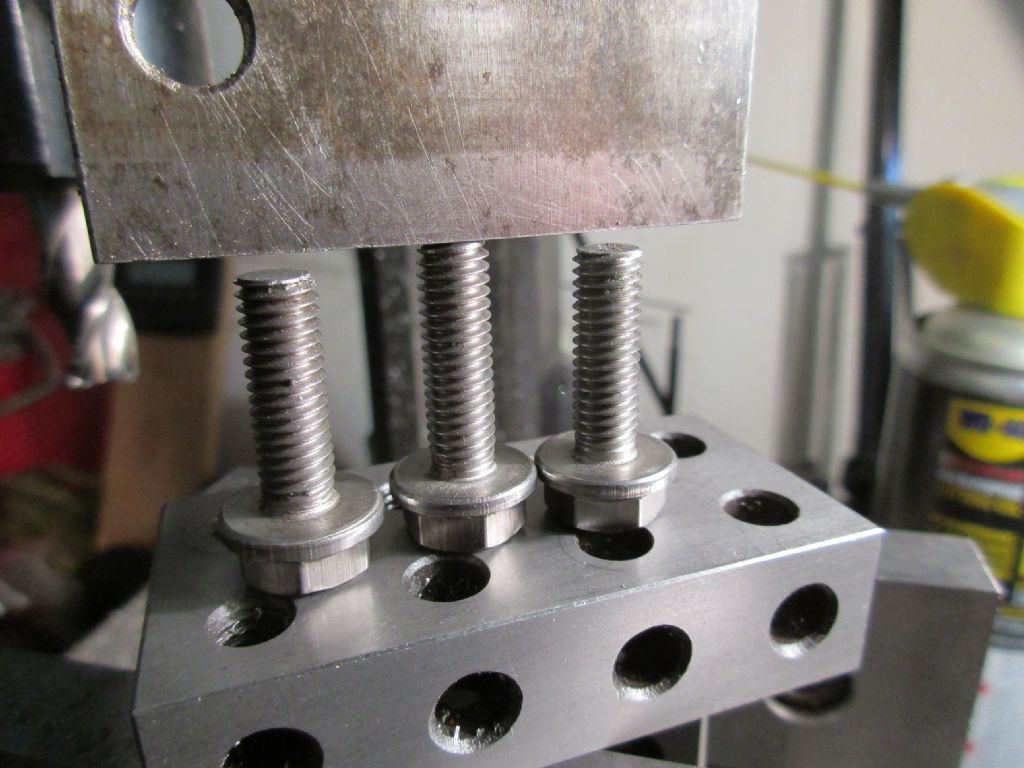

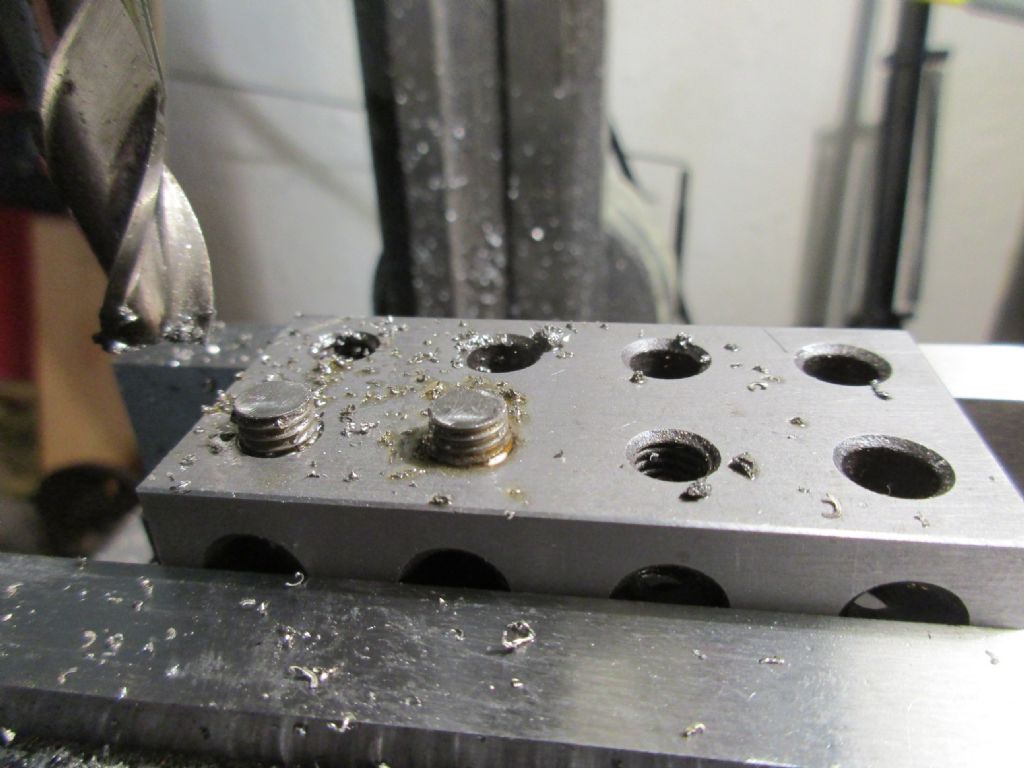

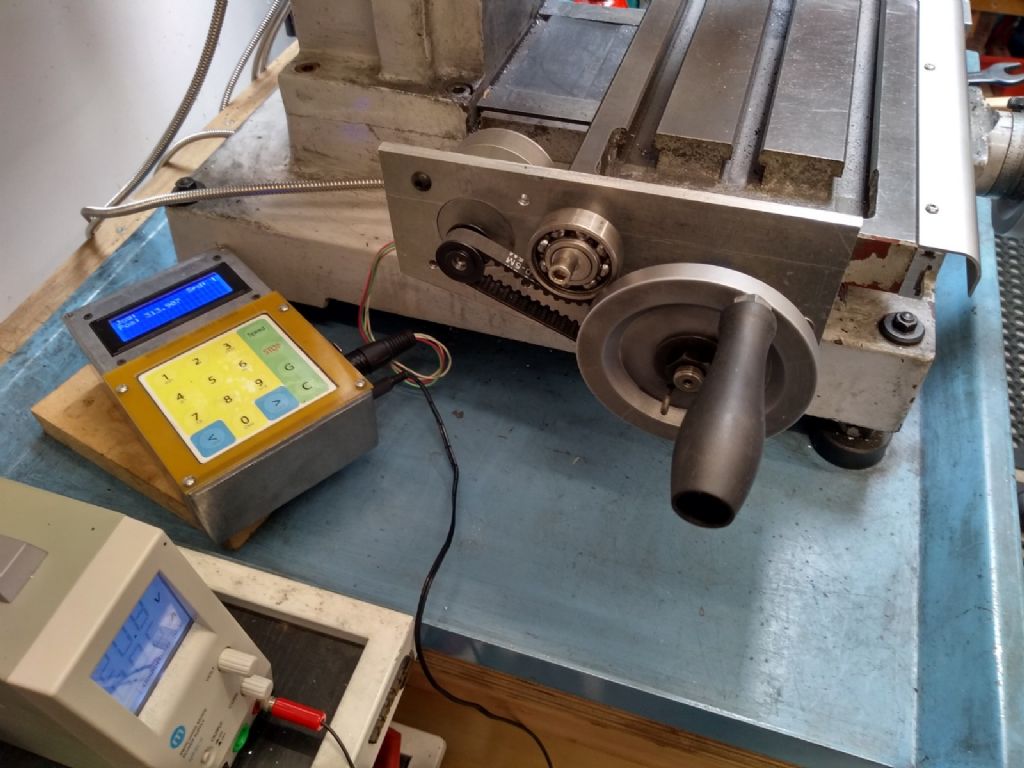

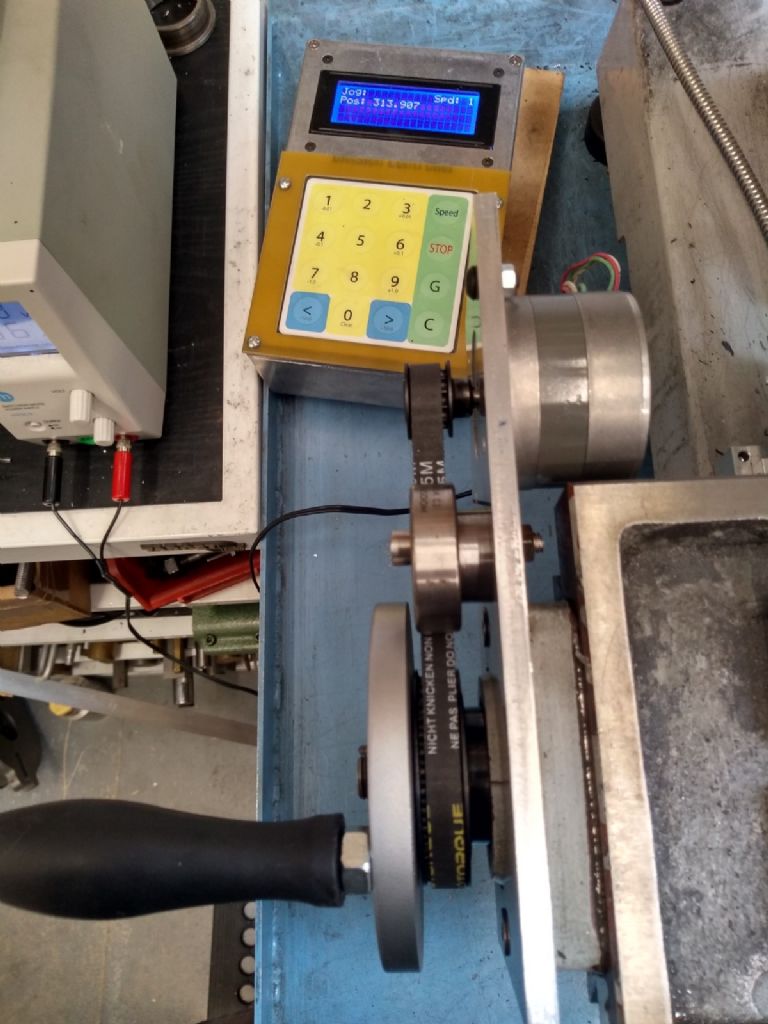

Me today? Continued with the steam-wagon but hit more problems, some from cumulative errors despite all care with handed-pair components; or from spotted-through bolt-holes having drifted. Others from having to design the thing as I go, often finding bits I made earlier (several years earlier!) interfere with the bits I am making now.

I'd envisaged the boiler sub-frame being also its lifting-frame but realised that would not be as straightforward as it seemed, so I am making a new tool for that purpose.

One unexpected snag will arise in making the new footplates necessary – 3 pieces of 16swg steel. I can cut it, by angle-grinder or manual sheet-saw if necessary, but the problem comes if I want to flange it. For the lock-down and travel restrictions bar me from a shared folder…. about 30 miles away.

My 'Warco' 3-in-1 tool is not designed for steel that thick. It may be pushing it to use the jenny I bought but have not yet used, though it's stated as up to 1.5mm. I could try MIG-welding flanges, but have limited welding skill and am worried about distortion.

'

Broke off in mid-afternoon for the usual cuppa but made something of it with appropriate props, to stage a humorous photo for my caving friends with whom I spend most normal Saturday afternoons underground then enjoying tea and cakes back at the club-house.

Our last caving session would have been seven weeks ago – my model-engineering club stopped earlier still, by some two or three weeks. Our track and club-room, and a public sports-centre, are in the grounds of a school that locked out external organisations earlier than the real lock-down. Leaves on the line? It'll be a linear compost-heap… Some of the society's ' Sixteen-Millers ' have been circulating videos of their own garden railways, which helps us all keep in at least some contact.

'

I do like what the good folk of Settle did for RNLI funds: a ' Bathe At Home Day '. Note – bathe not bath! A friend who lives in that fair town sent me a photo of her in cossie and brightly-coloured knitted bobble-hat, standing up to her tummy in the garden pond. She told me of another who used an old grow-bag filled with water.

Nigel Graham 2.