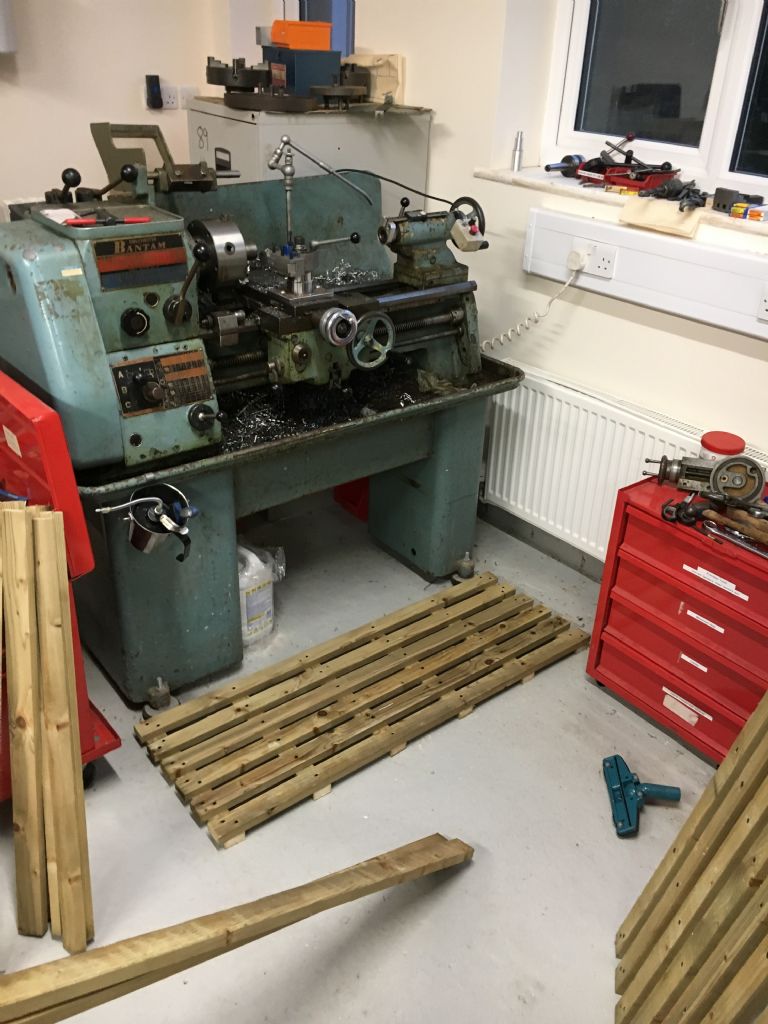

I'm afraid there was an outbreak of The Brown Stuff in the workshop this evening but I'm pleased to say I've contained it now. At the weekend I was at B&Q getting some bags of concrete and picked up sixteen 2.4m lengths of 2"x1" treated battens with a view to finally making up some duckboards for the machines. I have to admit I often (usually) end up wearing my slippers in the workshop. Yes, more M&S than H&S but worst of all so far has been the swarf that gets embedded in the soles and ends up all over the house. The domestic manager hadn't twigged yet but it would be only a matter of time.

Although completely and totally unnecessary, I modelled them up in Fusion as an exercise in using the parameter table to drive the configuration and dimensions. I was also trying to sus out how to create a series of near-duplicate 2D drawings with slightly different base parts. I set it up with user parameters that specified the number of longitudinal and lateral slats, along with the width and depth dimensions. Then created a 2D drawing for each showing the centre positions, slat lengths etc. Saved me measuring and marking ten times and still cutting and drilling in the wrong places.

Fusion is still not there when it comes to copying models and their associated drawings. To create a duplicate set, you have to archive the 2D drawing (using the A360 cloud control panel), then upload it again, back into Fusion. At that point you can rename the new files and create your alternative models / drawings. I'm sure they will get there at some point but right now it needs this work around.

The actual chopping up and screwing together was simple and quick in comparison, using a circular saw to cut bundles to the same length and a collated screwdriver (bandoliers of screws) to slap drywall screws in. I'm hopeful that these screws will be moderately rustproof.

Job done, finally!

Murray

Another JohnS.