Posted by John Stevenson on 21/10/2016 20:09:14:

Both values swap over. In Gearotic you can lay out this problem that Andrew has and animate it whilst playing "what if"

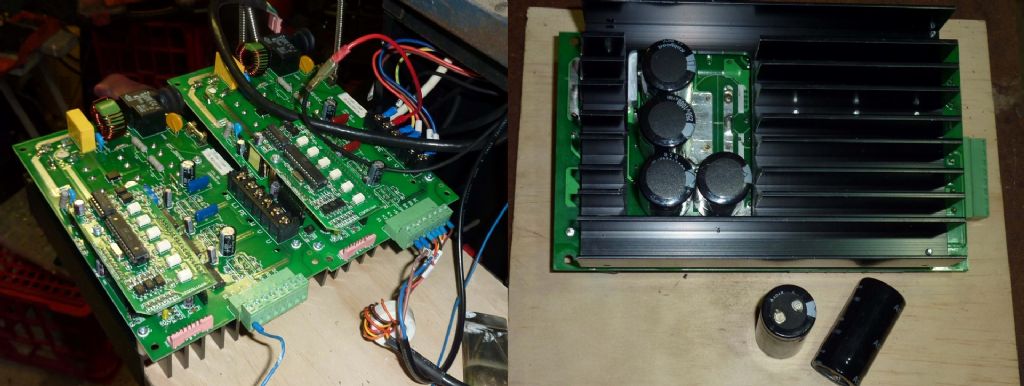

Quite so; I got Gearotic to generate an internal gear and pinion last night, having loaded it onto the new computer. I also managed to generate a helical gear. And then everything disappeared; whatever I did I just got a blank canvas.

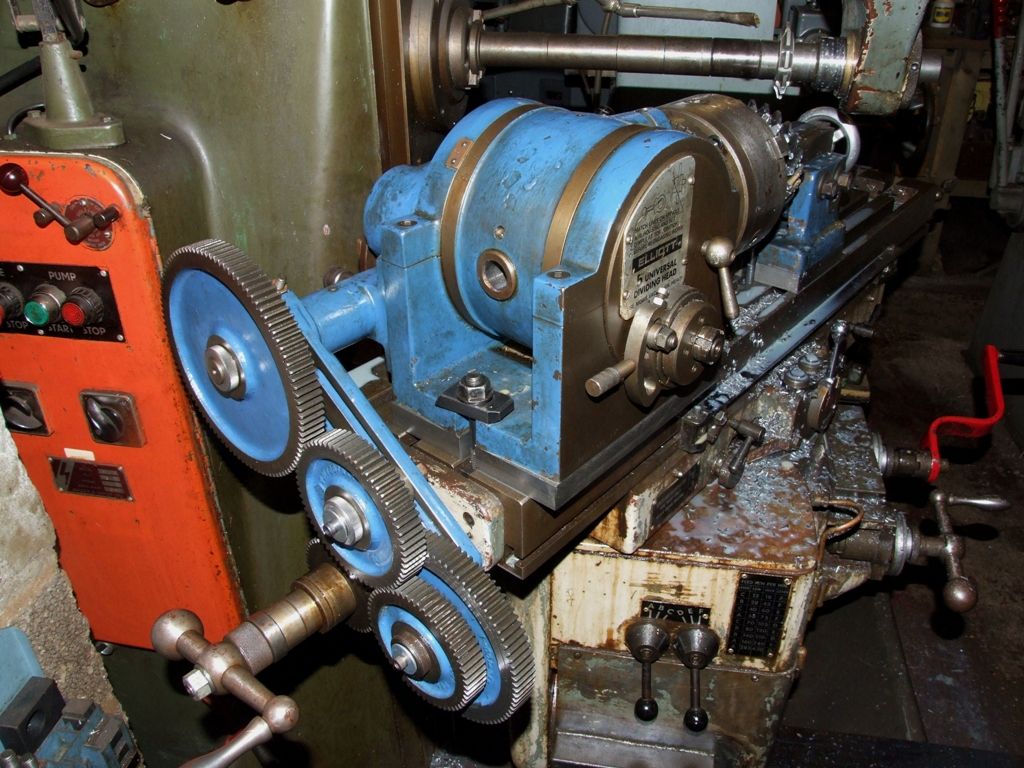

On a more practical note I took this afternoon off from working on the electronics for non-dispersive infrared sources and detectors and made the mating helical gear to my previous effort. For the gears to mate on parallel shafts the second gear needs to be lefthand rather than righthand. This involves swivelling the mill table in the opposite direction, and adding an idler gear to the gear train so that the dividing head rotates in the opposite direction. The idler gear can be clearly seen in the picture:

The setup was a right (or should that be left) faff. In order to maintain clearances I had to move the dividing head one set of T-slots over, move the cutter towards the overarm support and use my home made riser blocks so the division plate didn't clash with the table. Even then it was tricky to access the division plate to index the gear. It was made easier by having made the stop for the plunger on the division plate, so that I could lock it in the out position. That meant I was much less likely to accidentally move the indexing arms. All went well and the second gear appeared, on the left naturally:

They seem to mesh smoothly, and the centre to centre distance is as it should be, at least as measured with a rule.

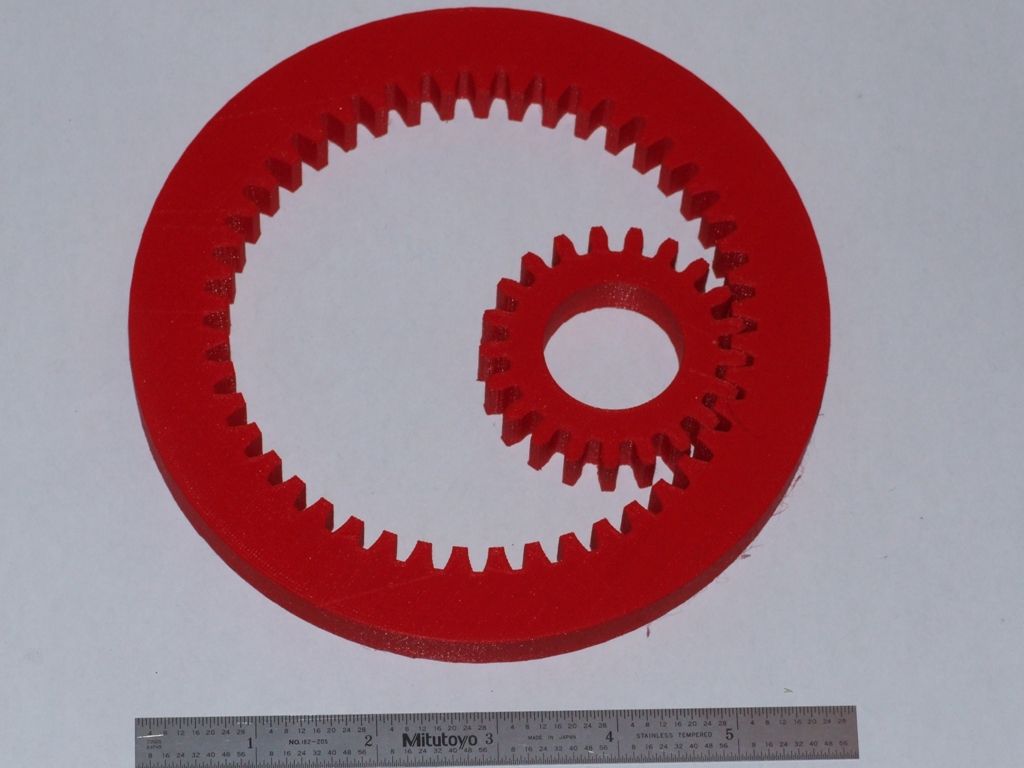

Tomorrow the plan is to do some 3D printing of internal gears and pinions, and have a play with the gearing on the dividing head to explore low leads. Sunday will be admin, and then I'm afternoon tug pilot.

Andrew

JasonB.

JasonB.

helical gear. The lead is about 164mm; it's too much for the table drive, it just stalls. However, it is quite hard work turning everything from the division plate. So I may play with the gear parameters before committing to machining. The exercise is just to make a high helix angle gear, it doesn't matter much what the actual parameters are. The other issue is that the cutter is all over the place. I'm not sure if that's because it's a cheap cutter, or I have a problem with the right angle head and/or arbor. Investigation needed.

helical gear. The lead is about 164mm; it's too much for the table drive, it just stalls. However, it is quite hard work turning everything from the division plate. So I may play with the gear parameters before committing to machining. The exercise is just to make a high helix angle gear, it doesn't matter much what the actual parameters are. The other issue is that the cutter is all over the place. I'm not sure if that's because it's a cheap cutter, or I have a problem with the right angle head and/or arbor. Investigation needed.