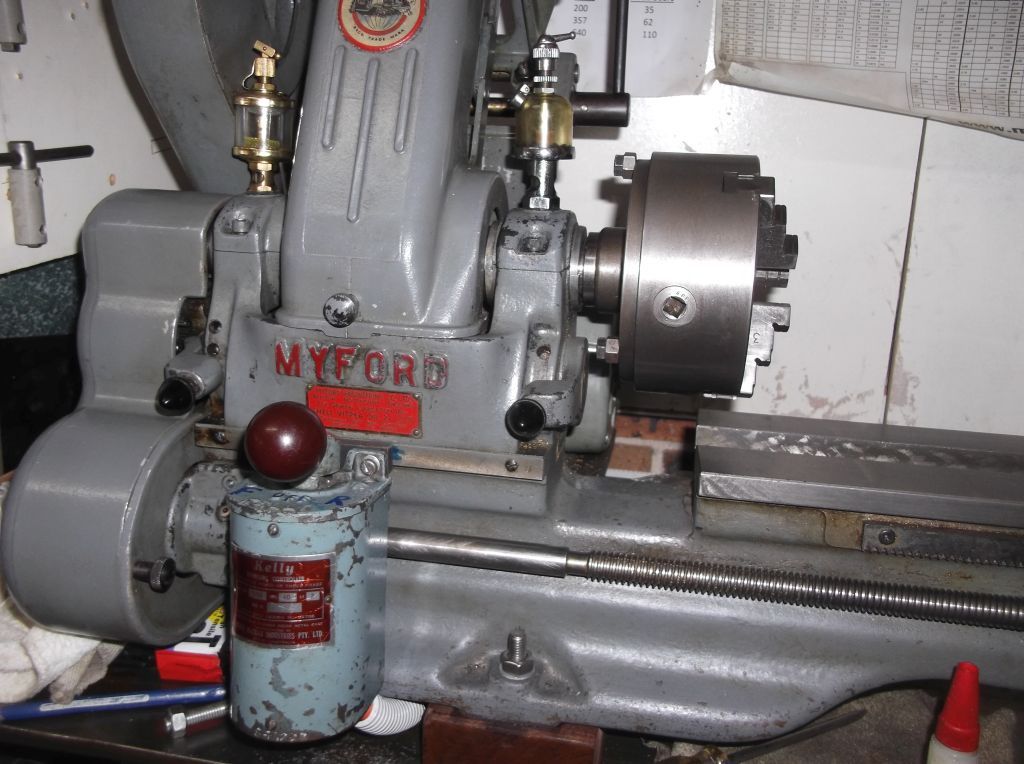

Not today only but finished milling the 'steps' (recesses?) in the buffer bars for my Cracker build. This required me to knock up a quick carriage lock as the milling cutter kept dragging the carriage along and ruining the piece…

Once that was fitted I set about milling the ends of the bars. Please note, my workholding set-up is very rudimentary and the finish is not to a high standard but the parts have ended up far squarer and to-dimension than I could manage by hand.

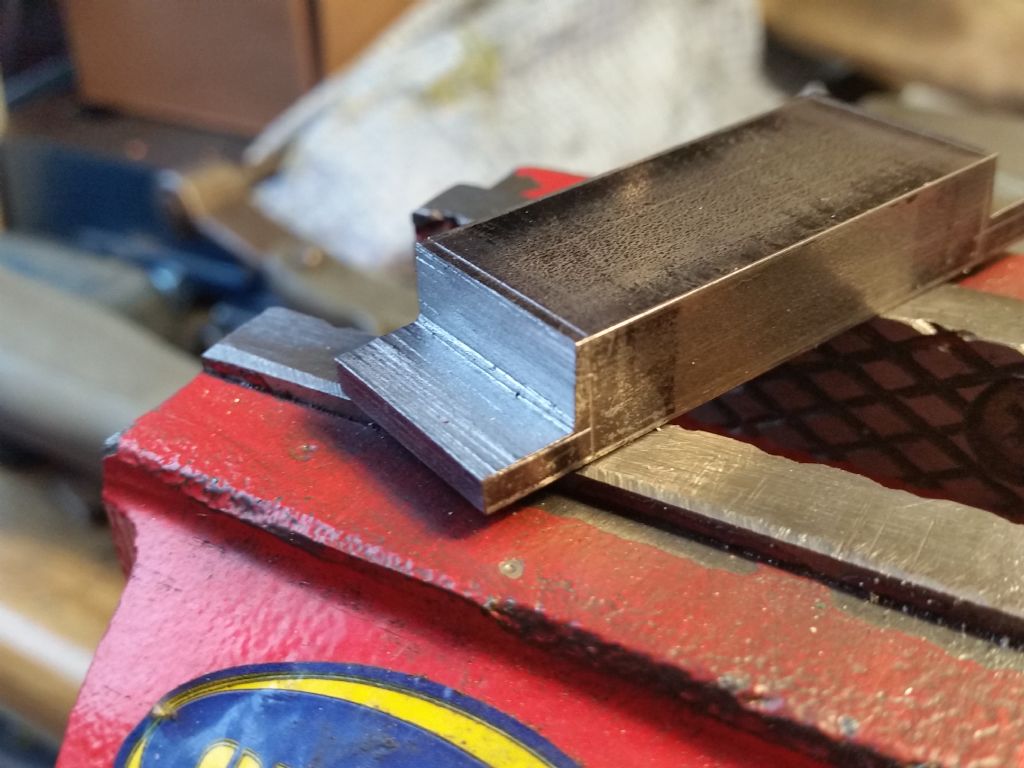

Marked out and rouged out with a hacksaw (this one was actually a ruined piece but you get the idea)…

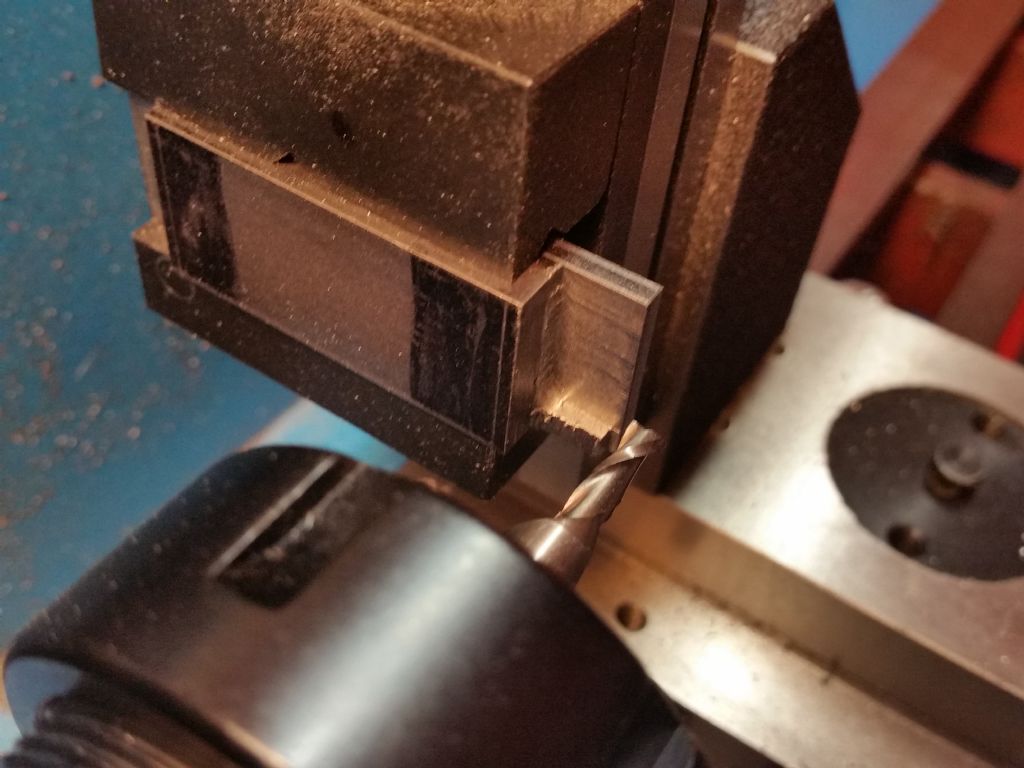

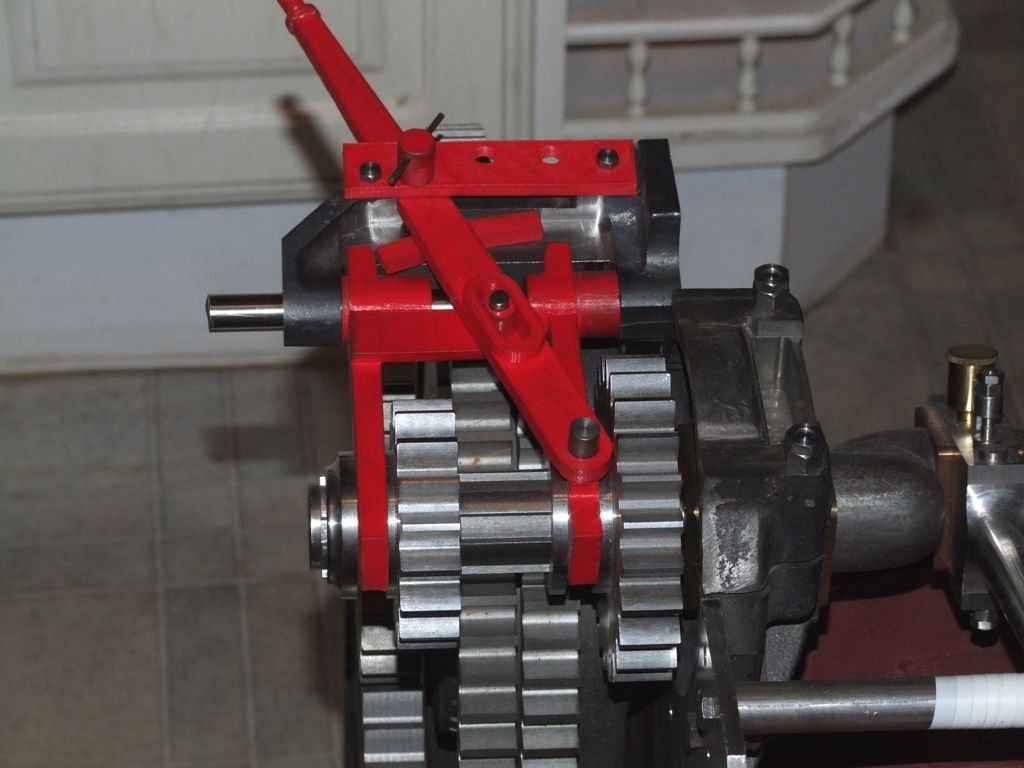

Then into the milling vice…

I have no idea if the 2-flute, 4mm cutter I used was right for the job. I tried to make sure the work was always fed 'at' the cutting flutes (climbing?) and used Tubal Cain's guide of 1/4 cutter diameter for 'plunge' depth and 1 diameter for maximum side cutting depth. Sometimes it 'felt' ok and sometimes it didn't. I settled on 2150 rpm. Cross-slide and vertical slide gibs are significantly tighter than when I started, as I kept tweaking them up a bit to keep it all moving in one plane only. So my fingers are a bit sore from turning the hand-wheels now.

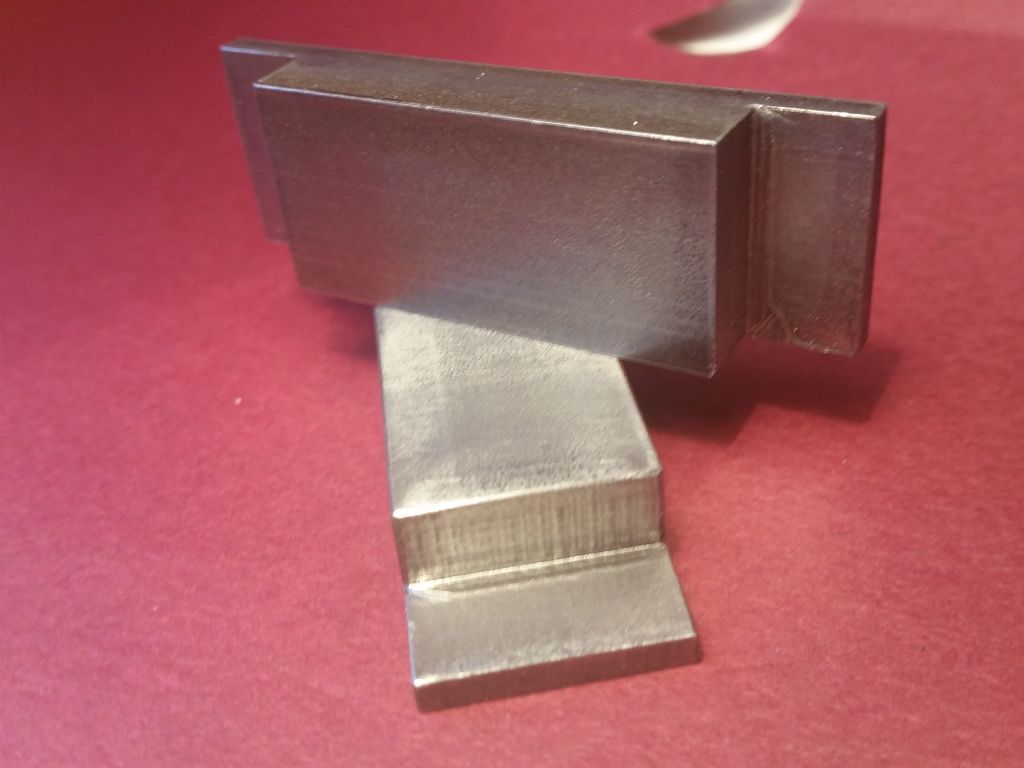

Eventually, and after 2 scrappages, I ended up with two matching (well, very close, much better than I could have hoped to do by hand) buffer bars…

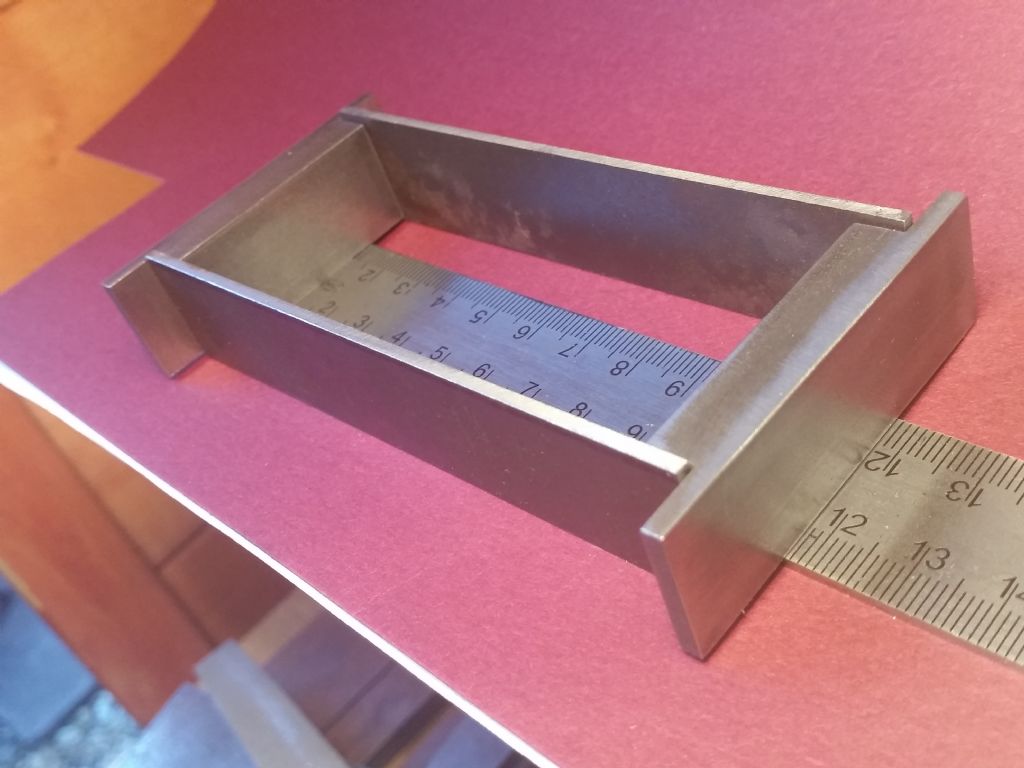

After that I couldn't resist a quick mock-up of the frames…

I've altered from the original design slightly. In the plan the buffers are only 10mm deep (instead of the 10X20 I used) and the frames are scalloped (?) to half depth for roughly their first and last third. I wanted to simplify the marking and cutting of the frames, and I think the end look will have a more British industrial NG vibe about it. Possibly.

Next will be drilling the frames, wheels/bushes/axles/gears(bought I'm afraid…), then I'll make a start on the oscillating motor. For those who don't know the model, it has a single, single-acting oscillating cylinder, mounded vertically on one side with a flywheel on the other.

I start my passenger hauling 2-10 Austerity next week…. Yeah in my dreams

to be .1599 on one side and .155 on the other !! The best I could do to satisfy this requirement, for press fitting pins, was to make a test bar accordingly, then use the lead-in of a hand reamer to achieve the nearest agreement. In practice, it worked out pretty well, the tiny taper in the holes being immeasurable.

to be .1599 on one side and .155 on the other !! The best I could do to satisfy this requirement, for press fitting pins, was to make a test bar accordingly, then use the lead-in of a hand reamer to achieve the nearest agreement. In practice, it worked out pretty well, the tiny taper in the holes being immeasurable.