Posted by Oompa Lumpa on 31/05/2014 22:20:18:

And just to continue with the "what I did" theme. Today I learned that maybe a CNC Mill would be a good idea. Watch this space!

graham

And if you had a day like me today you would think twice

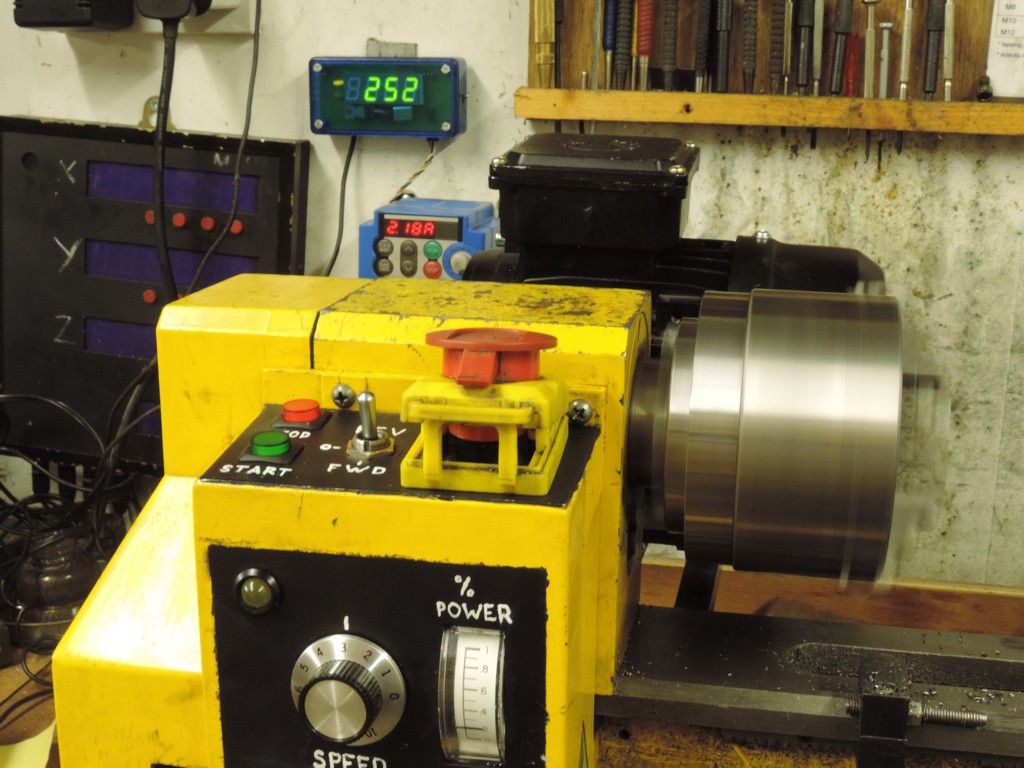

Got the prototype of the old X3 here, decent machine but mucho modified from a standard X3, things like ER32 direct into the spindle, two speed belt drive from a proper AC motor and inverter and a lot more under the hood.

It's a work horse and gets used for little production runs so today it's got to drill 5 holes in 100 pieces of pre-cut alloy plate, stupidly simple job that the code is written on the fly, no programming.

First problem is it's been that long since it was last used the computer bios has lost it's settings, so re-enter all the settings and start setting the job up. turn round and it fell over, reboot, put all the settings in and carry on.

Take a phone call and come back and it fell over again.

Drag the computer out the base, take to side off and replace the battery, re boot, enter settings a-gain [ best Forrest Gump voice ] leave switch on for 10 minutes, power down and up and it's remembered all the settings.

Yer hoo

All set up, program written and tweaked, 3 bits done and half way thru the 4th it just stops.

Shout out loud words like Oh golly gosh [ or close to ]

Boot it up and get all the relative information off it on a memory stick. drag a *new* computer from out the hay loft and configure this up for Mach. Reason I stuck with the old one was so as not to go down this path because of drivers for touch screen etc, etc.

Anyway back up and running, machined all the rest with not one problem and then ran the other computer over with the fork truck, see how you like that Mr Gates ?

John Haine.